Hydraulic circuit arrangement, in particular for the drive of concrete distributor masts

A line layout and drive device technology, applied in the field of hydraulic loads, can solve problems such as lack of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

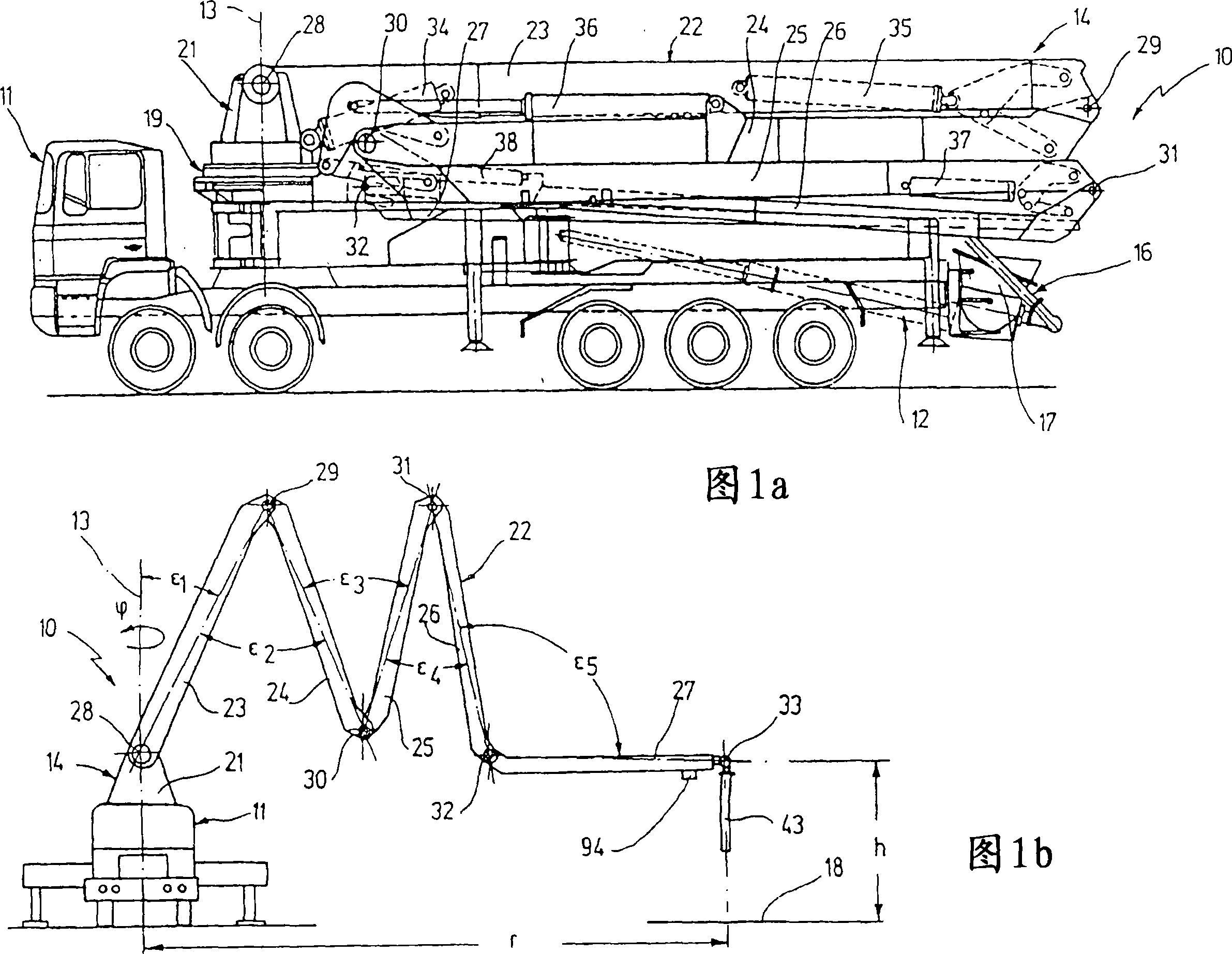

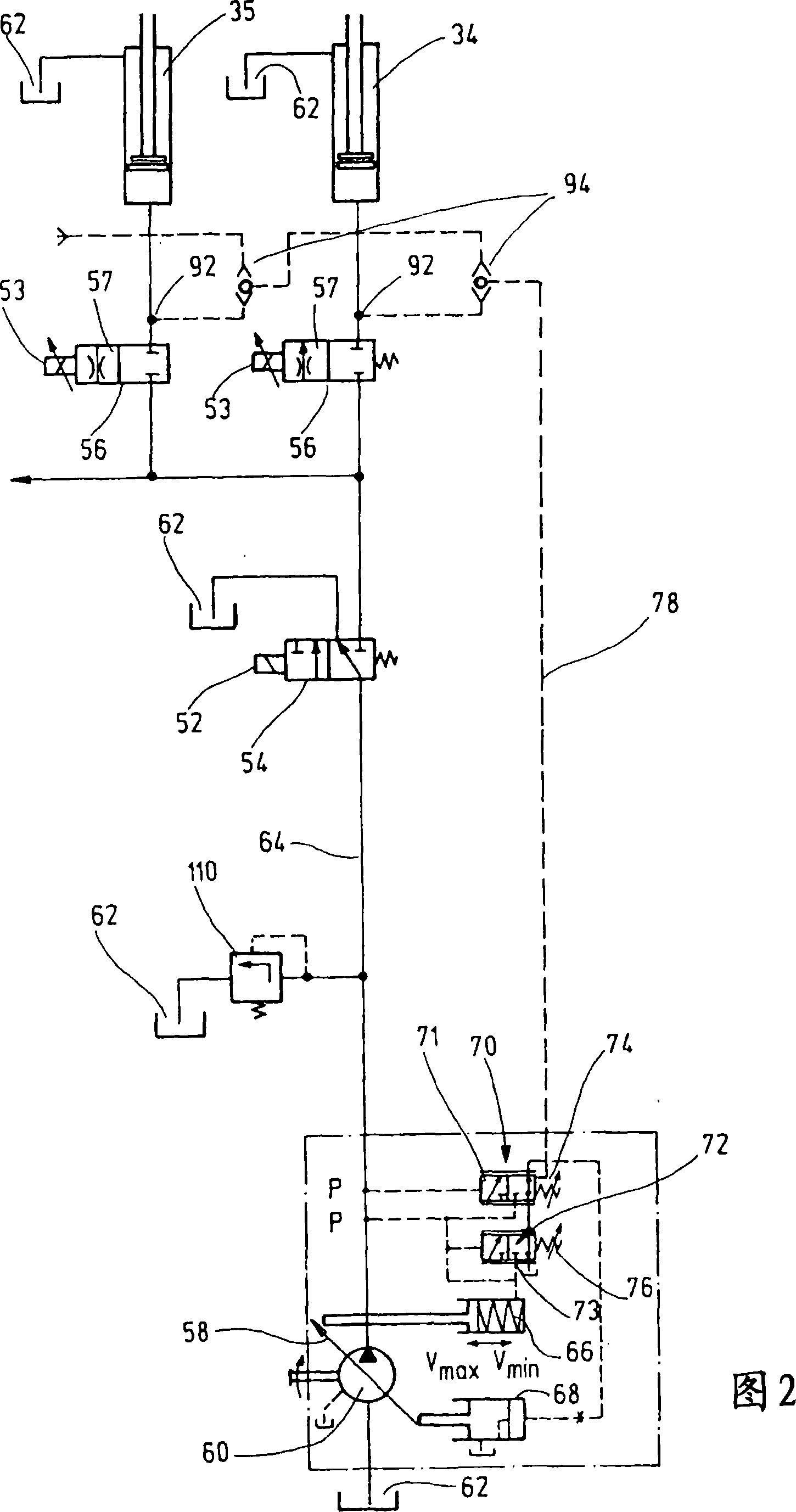

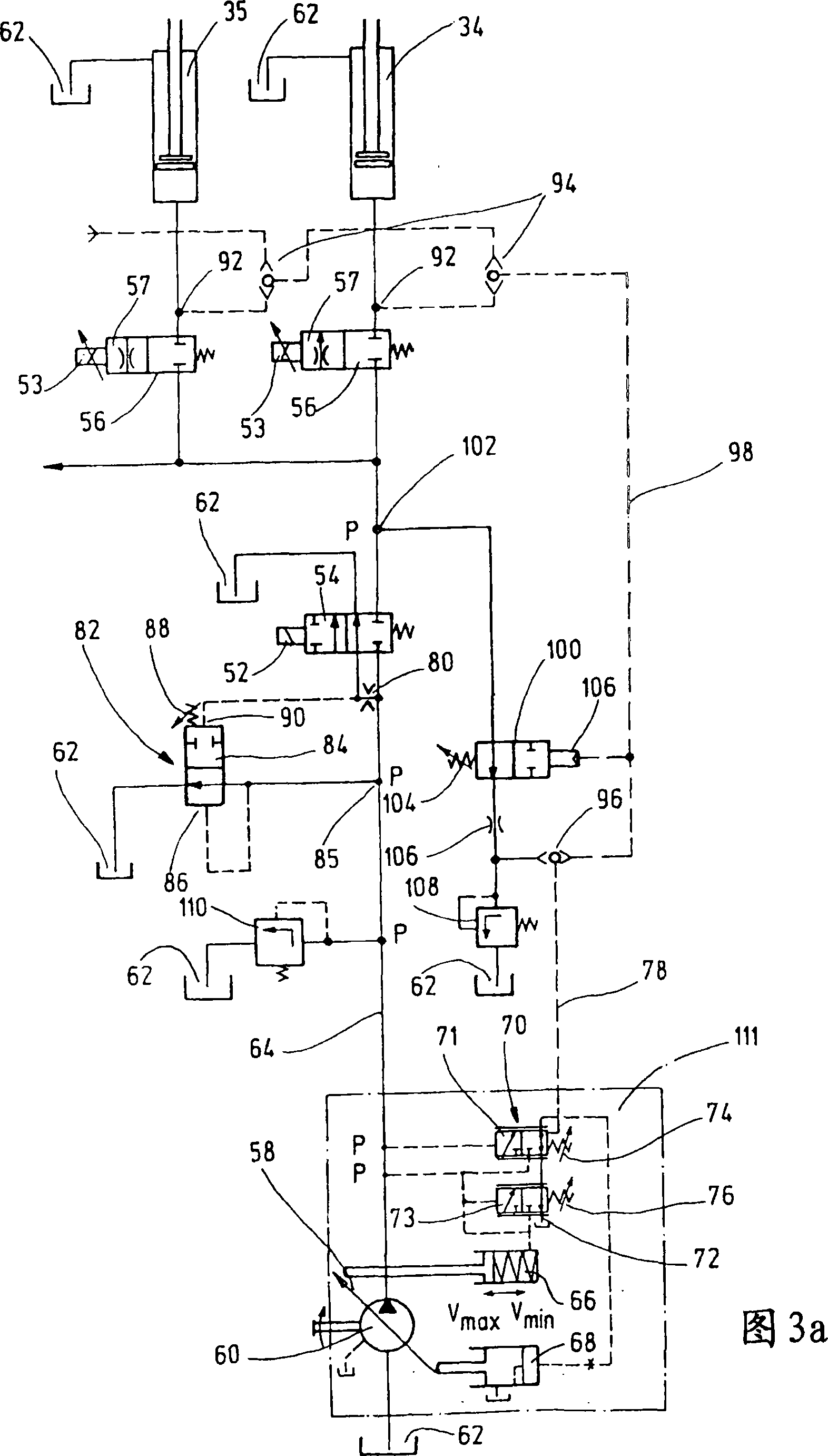

[0022] The hydraulic wiring arrangement shown in FIGS. 2 to 4 can be used, for example, to control the drive unit designed as hydraulic cylinders 34 to 38 of the self-propelled coagulation pump distribution boom 14 .

[0023] For illustration, Figures 1 a and b show an example of a self-propelled coagulation pump 10 comprising a transport vehicle 11, a mud pump 12, for example designed as a double-cylinder piston pump, and a concrete delivery pipe rotatable about a vertical axis 13 fixed on the vehicle Concrete placing boom 14 of 16 brackets. The liquid concrete that is continuously added into the feed hopper 17 during concrete pouring is delivered to a concrete pouring point 18 far away from the parking position of the vehicle 11 through the concrete delivery pipe 16 .

[0024] The distribution boom 14 is composed of a rod base 21 that can be rotated by an angle p around the vertical axis 13 by means of a hydraulic rotary drive device 19, and a hinged rod 22 that can rotate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com