Improved Oil Filled Cable

A technology for oil-filled cables and oil passages, which is applied in the direction of insulated cables, power cables, cables, etc., can solve the problems of complicated operation, inconvenient installation and use, and inconvenient arrangement, so as to prevent air gaps and oil immersion in a balanced and stable state. Good effect in oil immersion state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

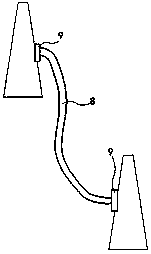

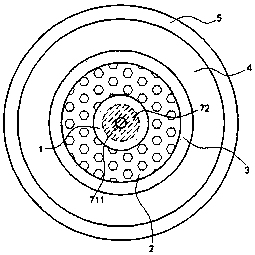

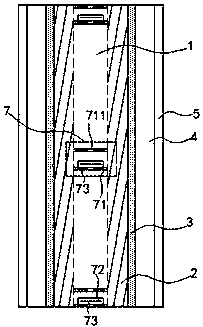

[0015] exist Figure 1 to Figure 3 In the shown embodiment, the improved oil-filled cable 8 includes an oil passage 1, a wire conduit 2, a shielding layer 3, an insulating layer 4 and a protective sheath 5 from the inside to the outside; the oil passage 1 is filled with insulating oil ; The wire conduit 2 is tightly twisted together by a metal wire, and the wire is wrapped by insulating oil-impregnated paper; two ends of the improved oil-filled cable 8 are also installed with the oil channel 1 communicated Oil storage tank 9; the oil passage 1 is made of a hard oil-immersed film, and throttle valves 7 are equidistantly installed on the axis of the oil passage 1, such as image 3 Shown in the thin dotted line frame; each of the throttle valves 7 includes two throttle plates 71 perpendicular to the axis of the oil passage 1, and a throttle hole 711 is opened on each of the throttle plates 71; A throttle plug 72 is movably installed between the throttle plates 71, and the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com