Modular brake lining system and brake lining

A brake lining, modular technology, applied in the direction of friction lining, brake type, brake components, etc., can solve the problem of brake lining matching braking situation, etc., to improve air guide, optimize wear, and reduce wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

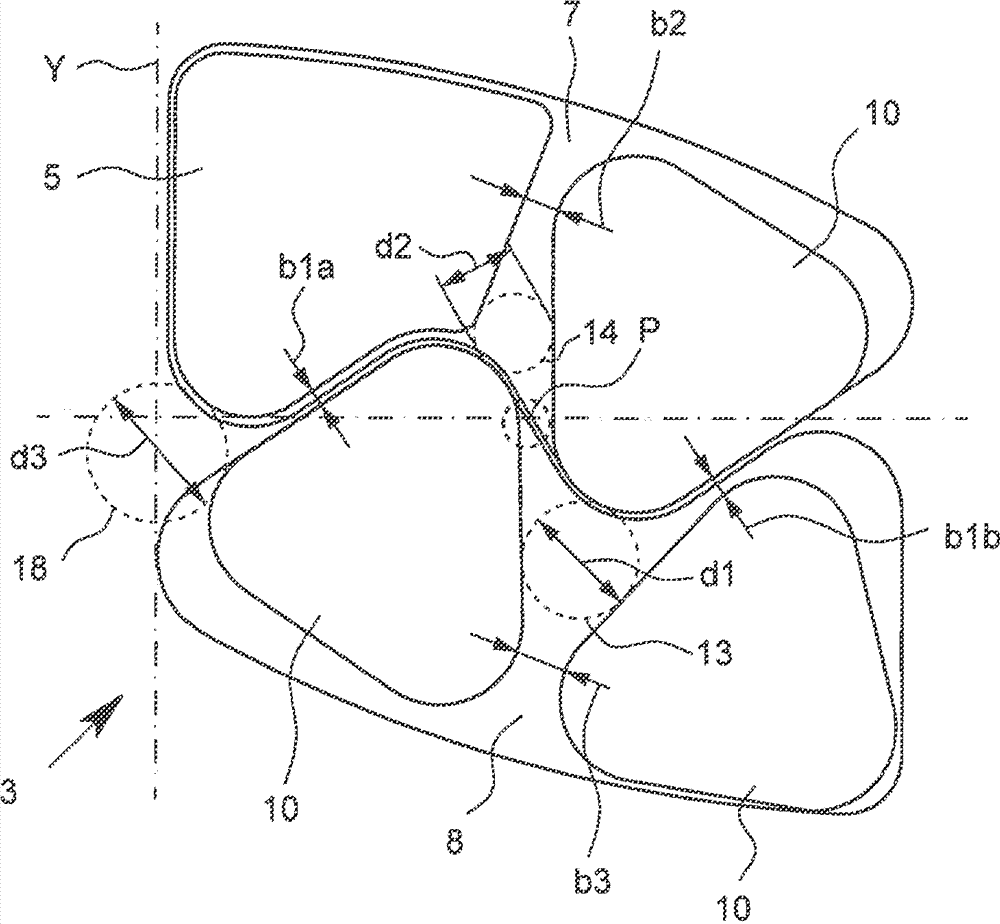

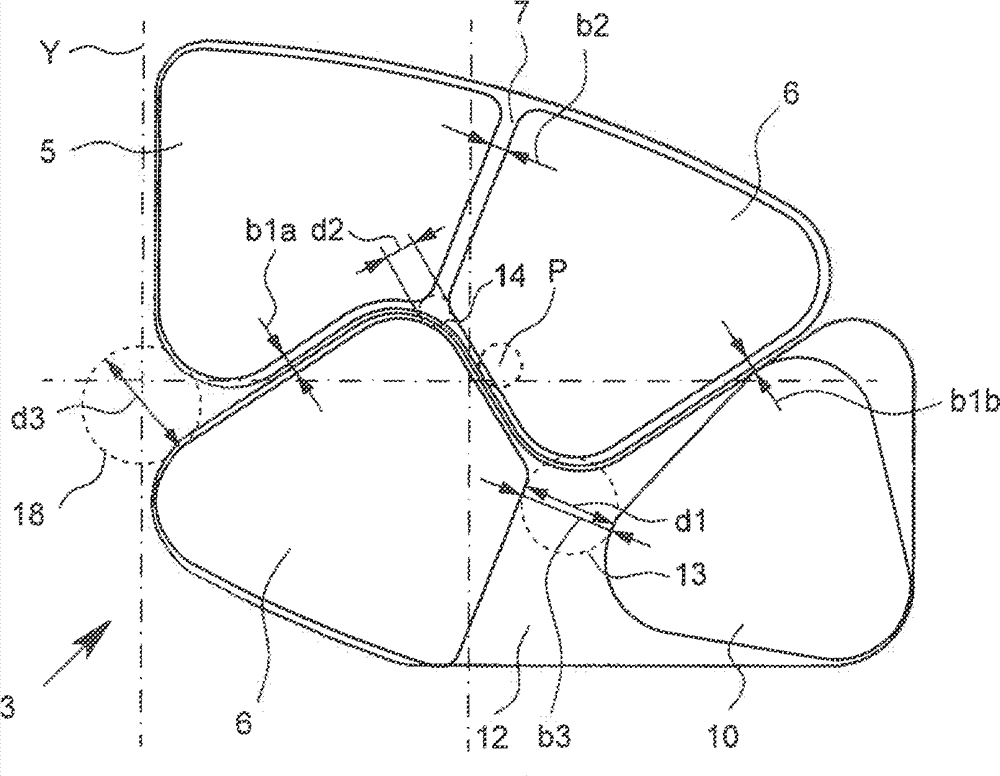

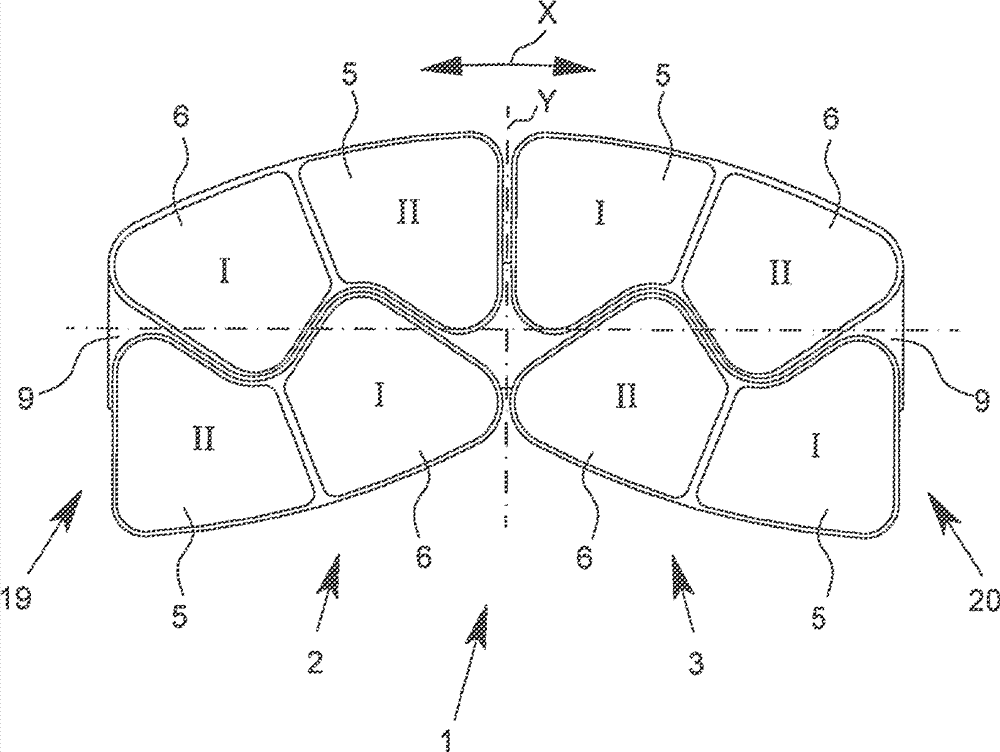

[0033] exist figure 1 shows schematically the arrangement of a brake lining 1 with two brake lining halves 2 , 3 relative to a brake disk 4 of a disk brake of a rail vehicle. The vertical plane of the brake disc 4 and the middle transverse axis Y of the brake lining 1 or the brake lining support are at figure 1 Fold in the layout scheme shown in . It is to be understood, however, that normally the horizontal axis of the brake disc 4 and the central transverse axis Y of the brake lining 1 coincide in the installed situation. In this case, the central transverse axis Y runs through the two brake lining halves 2 , 3 .

[0034] Each brake lining half 2 , 3 has up to four different friction segments 5 , 6 , wherein in each case two friction segments 5 , 6 are fastened releasably on the carrier plate 7 , 8 . The friction segment 5 and the friction segment 6 have different friction surface geometries or contours. as by Figure 14 and 15 As a result, the respective two carrier p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com