Process method for repairing and strengthening 17-4PH part by laser

A technology of laser repair and process method, applied in the direction of metal material coating process, coating, etc., can solve the problems of blade fracture failure, wear, harsh working conditions, etc., to achieve small impact, low dilution rate, small process heat affected zone Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of technological method of laser repair strengthening 17-4PH parts, comprises the following steps:

[0039] (1) Remove defects and oil stains on the surface of 17-4PH parts (substrates);

[0040] (2) Use (adjusted and optimized) composite laser melting deposition powder for repair and strengthening to obtain repair parts;

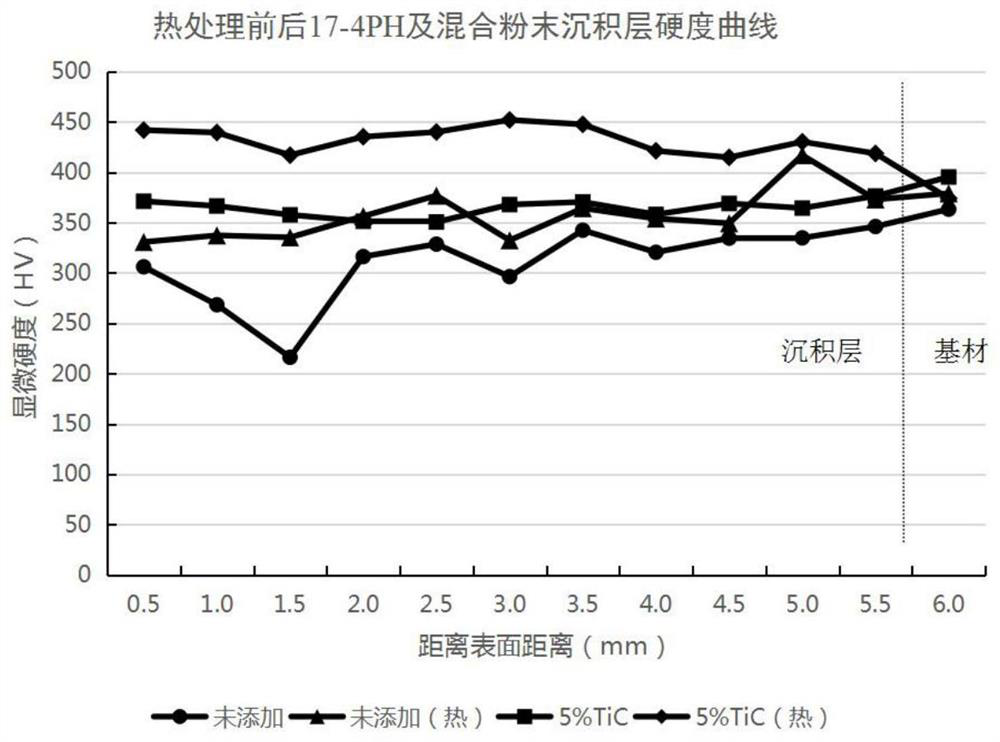

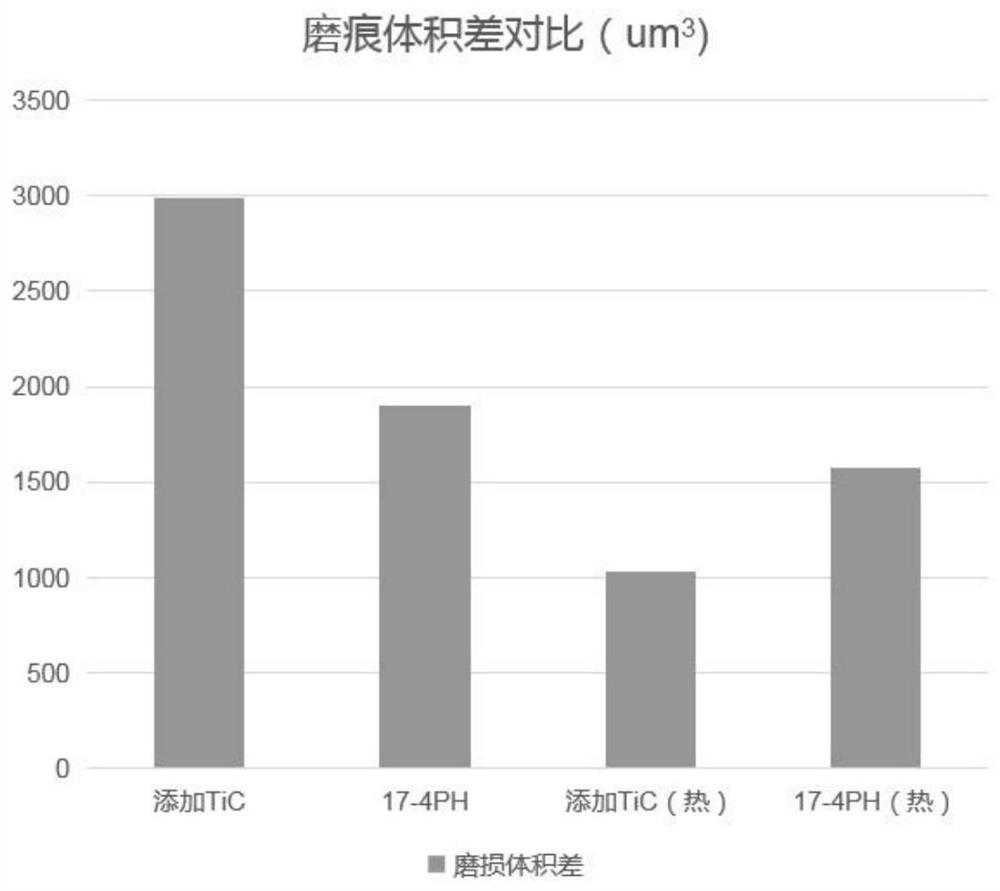

[0041] (3) Carry out aging heat treatment to described restoration, further strengthen coating performance;

[0042] (4) Finishing.

[0043] Preferably, in step (1), the 17-4PH part is clamped on a lathe, and after the oil stain is cleaned with a cleaning agent, the surface defects of the 17-4PH part are machined to expose fresh metal.

[0044] Preferably, in step (2), the dry composite laser melting deposition powder is added to a laser powder feeder, and then repaired by laser melting deposition to obtain a repaired part.

[0045] Preferably, in step (2), the dry composite laser melting deposition powder is added to the laser powder feede...

Embodiment 2

[0051] A kind of technological method of laser repair strengthening 17-4PH parts, comprises the following steps:

[0052] (1) Remove defects and oil stains on the surface of 17-4PH parts (substrates);

[0053] (2) Use (adjusted and optimized) composite laser melting deposition powder for repair and strengthening to obtain repair parts;

[0054] (3) Carry out aging heat treatment to described restoration, further strengthen coating performance;

[0055] (4) Finishing.

[0056] In this embodiment, in step (1), the 17-4PH part is clamped on the lathe, and after the oil stain is cleaned with a cleaning agent, the surface defects of the 17-4PH part are machined to expose fresh metal.

[0057] In this embodiment, in step (2), the dry composite laser melting deposition powder is added to a laser powder feeder, and then repaired by laser melting deposition to obtain a repaired part.

[0058] In this embodiment, in step (2), the dry composite laser melting deposition powder is added...

Embodiment 3

[0064] A kind of technological method of laser repair strengthening 17-4PH parts, comprises the following steps:

[0065] (1) Remove defects and oil stains on the surface of 17-4PH parts (substrates);

[0066] (2) Use (adjusted and optimized) composite laser melting deposition powder for repair and strengthening to obtain repair parts;

[0067] (3) Carry out aging heat treatment to described restoration, further strengthen coating performance;

[0068] (4) Finishing.

[0069] In this embodiment, in step (1), the 17-4PH part is clamped on the lathe, and after the oil stain is cleaned with a cleaning agent, the surface defects of the 17-4PH part are machined to expose fresh metal.

[0070] In this embodiment, in step (2), the dry composite laser melting deposition powder is added to a laser powder feeder, and then repaired by laser melting deposition to obtain a repaired part.

[0071] In this embodiment, in step (2), the dry composite laser melting deposition powder is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com