Ceramic sliding vane

A sliding vane and ceramic technology, applied in the field of ceramic sliding vanes, can solve the problems of poor lubrication characteristics, low temperature aging and high cost, and achieve the effects of reducing wear and friction loss, good corrosion resistance and good wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] see Figure 1 to Figure 4 , the present invention provides a ceramic sliding vane for a rotary compressor.

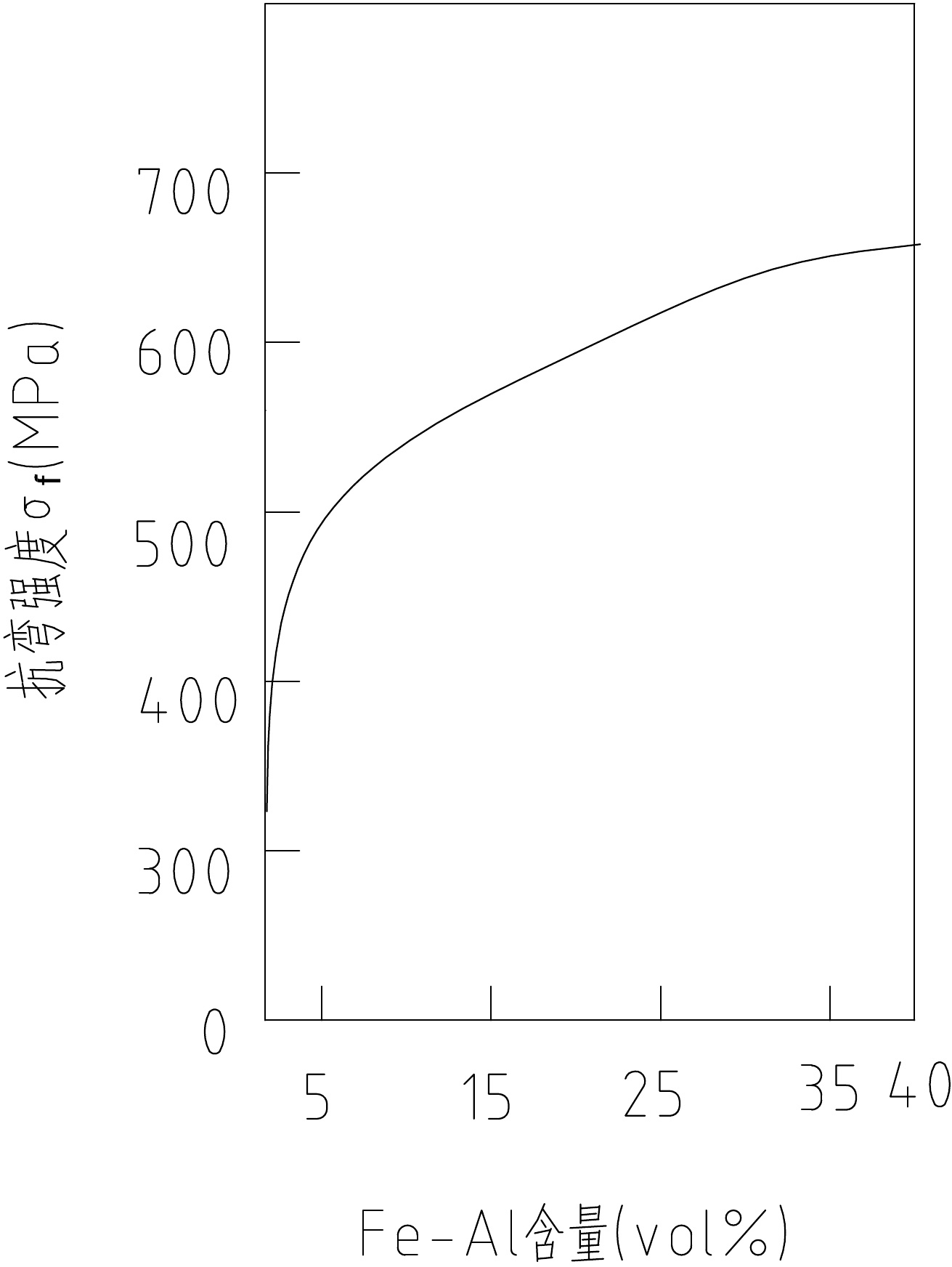

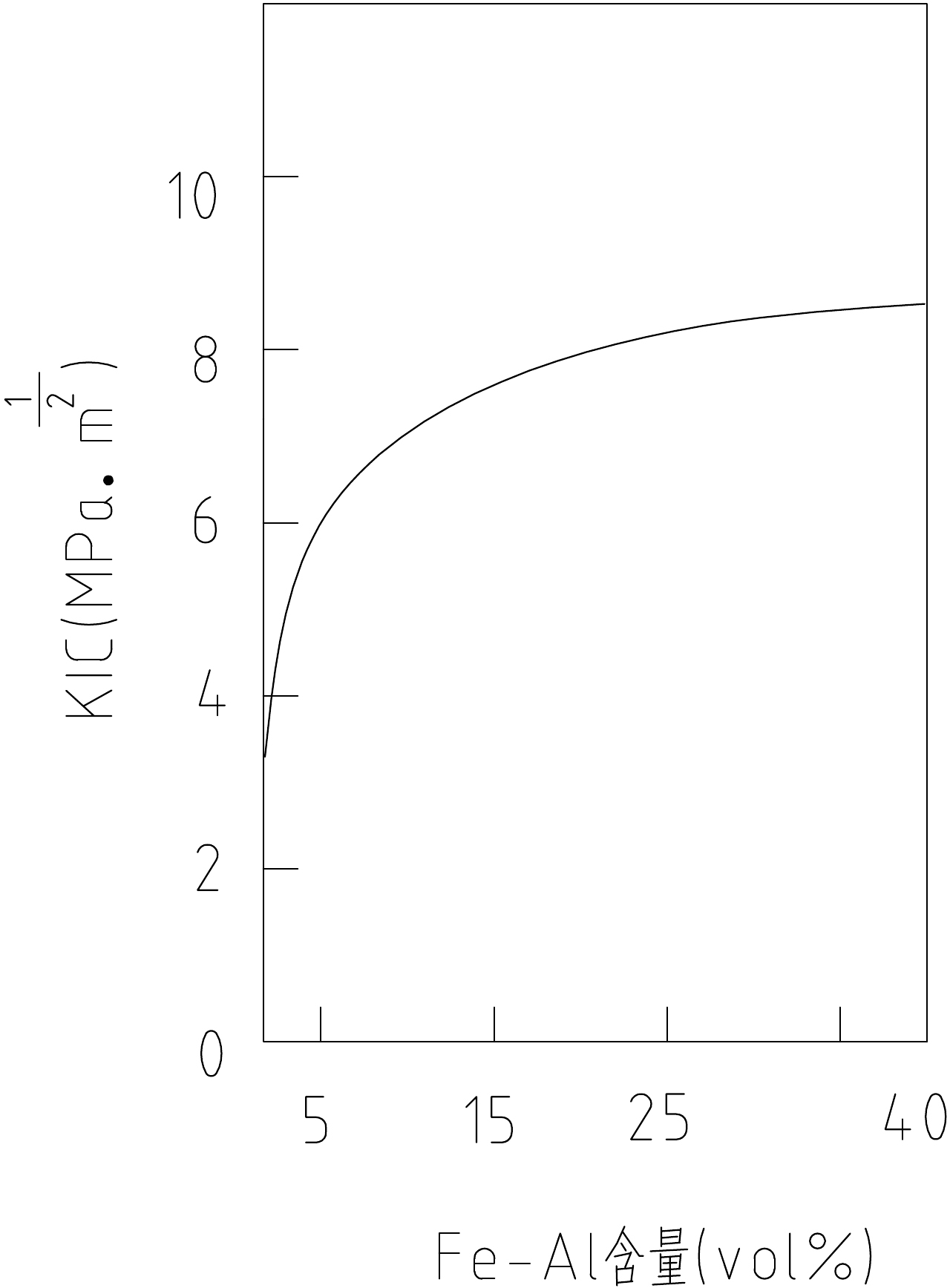

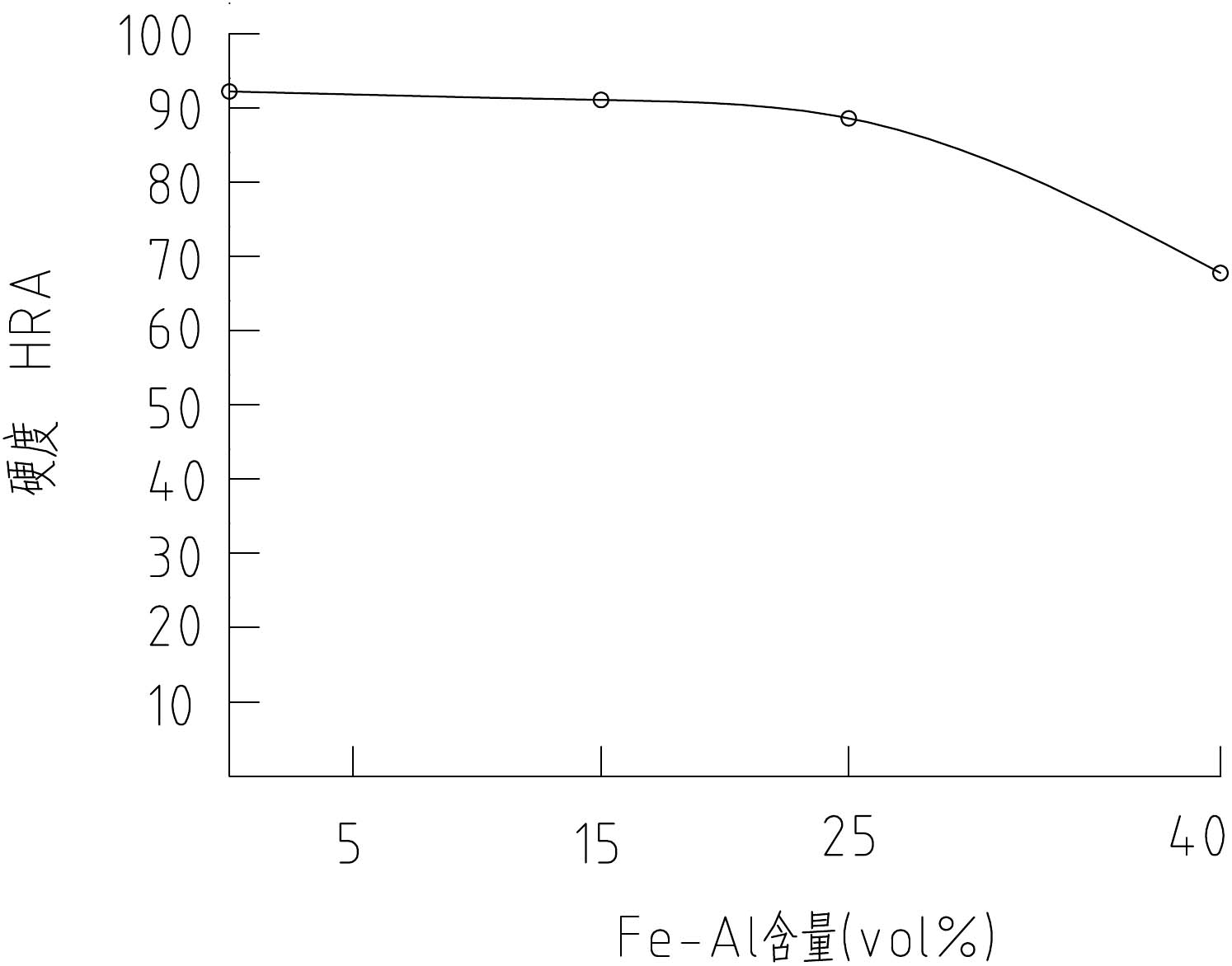

[0019] The ceramic slide includes a sintered body and a stabilizer, the sintered body includes 50% to 94.5% by weight of alumina and 5.0% to 40% by weight of Fe-Al intermetallic compound, and the stabilizer accounts for 0.5 to 10% by weight . In this example, the stabilizer includes La 2 o 3 , Y 2 o 3 、TiO 2 , MgO, Cr 2 One or more of metal oxides such as O3, SiO2, CaCO3 and BaCO3. The ceramic sliding plate of the present invention reduces the firing temperature of the sliding plate by adding a stabilizer, and suppresses the grain growth of the composite alumina ceramic to control the grain size, improve the wear resistance of the sliding plate, reduce the firing temperature and improve sintering body microstructure.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com