A new spring pre-strengthening and finishing compound shot peening method

A shot blasting and finishing technology, applied in the direction of abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of large surface roughness and reduce surface roughness of spring steel, achieve large residual compressive stress, improve mechanical properties, and hardness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Pre-strengthening and finishing composite shot peening

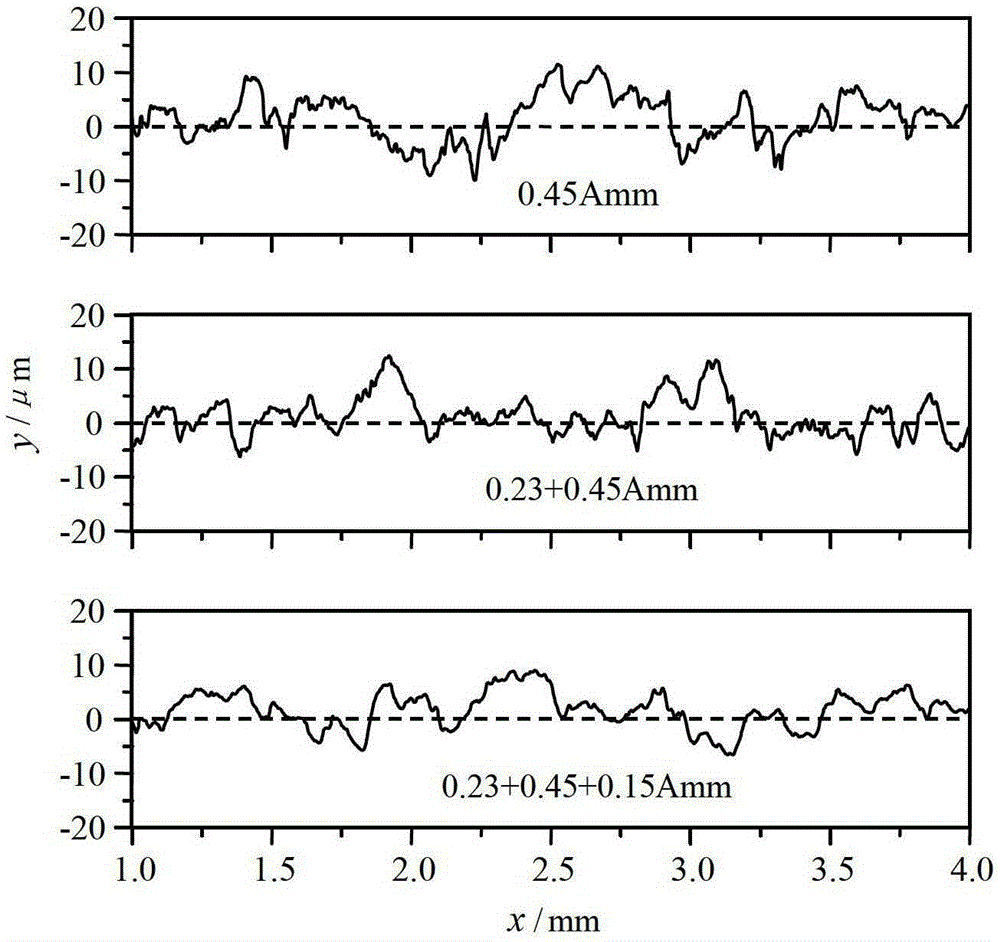

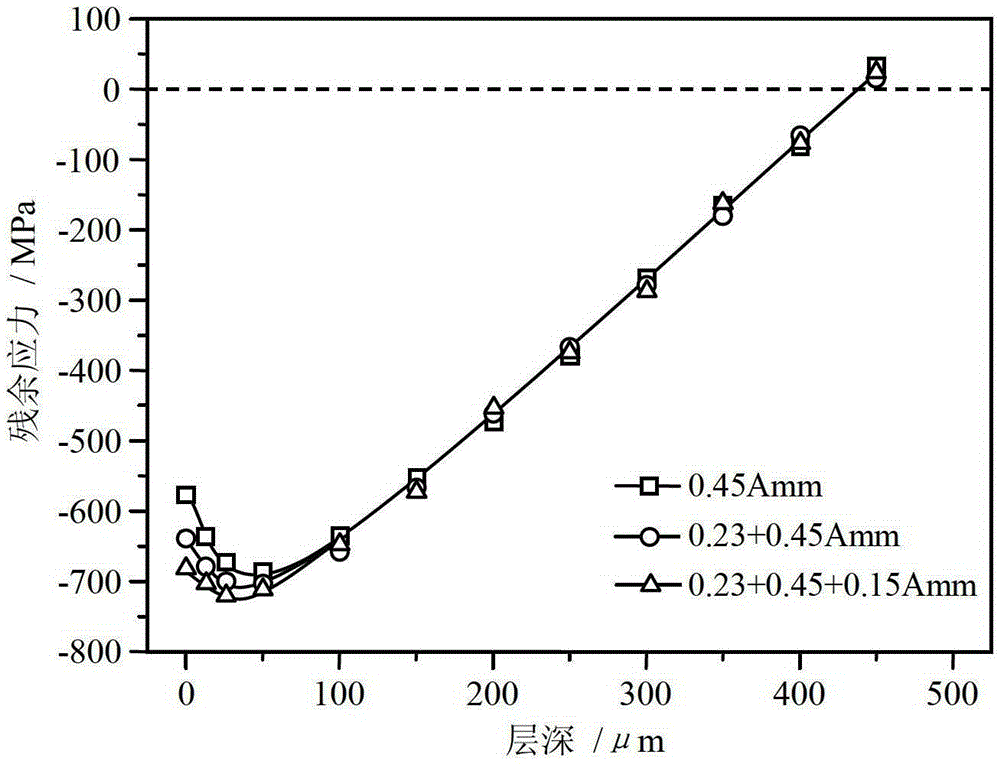

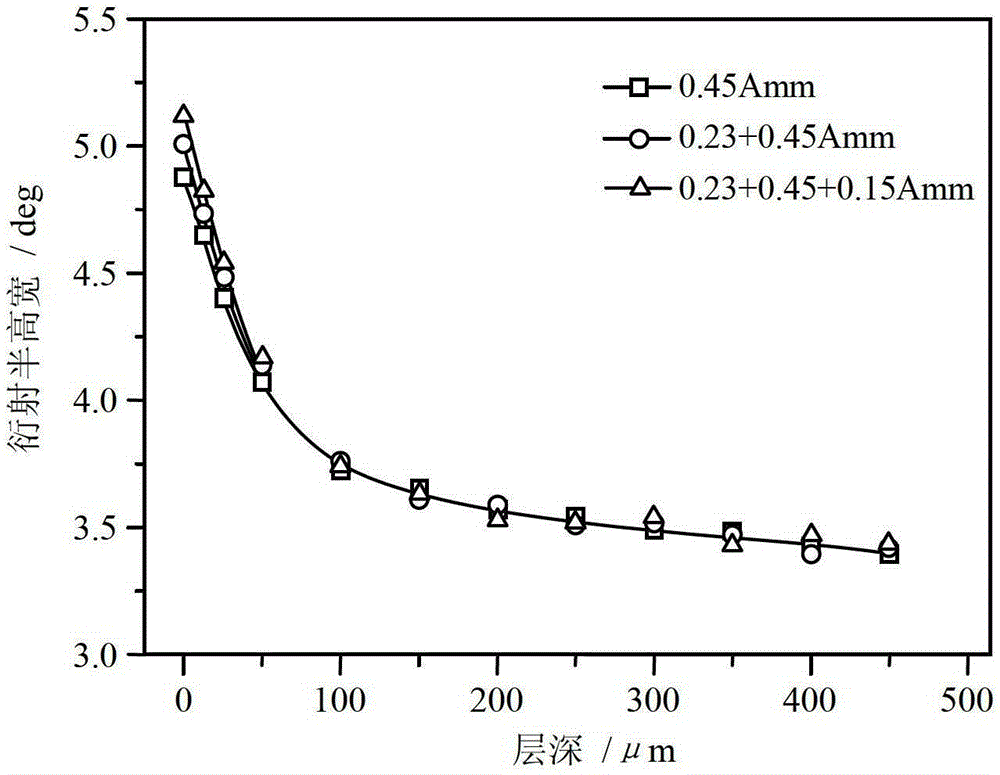

[0041] A shot peening machine is used to carry out pre-strengthening and finishing compound shot peening treatment on the spring. The pre-strengthening and finishing compound shot peening treatment includes three processes: the shot peening intensity of the first process is 0.23Amm, the shot peening intensity of the second process is 0.45Amm, and the second process is 0.45Amm. The shot peening intensity of the three processes is 0.15Amm, and the shot medium of the three shots is the same, and the third 0.15Amm finishing shot peening can further reduce the surface roughness of the shot peening to obtain a processed spring product.

[0042] The shot blasting machine is a pneumatic shot blasting machine, the shot medium used in the pneumatic shot blasting machine is G3 steel wire cut shot, the shot diameter is 0.6mm, and the shot hardness is 55HRC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com