High-efficiency wax removal water for metal workpieces and preparation method thereof

A technology for metal workpieces and wax removal water, which is used in the field of industrial cleaning agents in fine chemicals, which can solve the problem that dust and metal dust cannot be completely removed, the color of metal workpieces is easy to cause corrosion, and can not achieve wax removal, oil removal, and ash removal. and other problems, to achieve the effect of protecting the original color, high wax removal efficiency and good oil removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

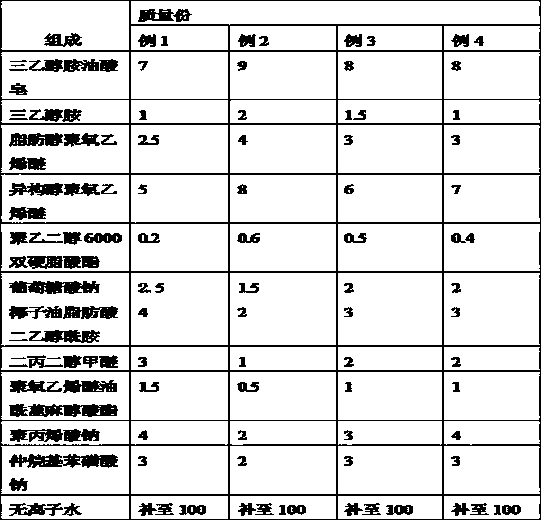

[0041] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The present invention will be further described in detail below in conjunction with the examples.

Embodiment

[0042] Embodiment: as follows

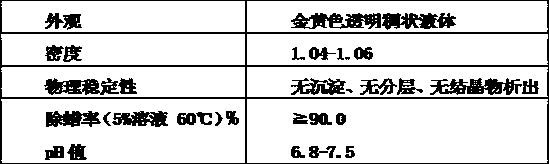

[0043]

[0044] Explanation: The sodium gluconate described in the present invention can be replaced by two components such as sodium gluconate and sodium silicate in an appropriate ratio; each of the above-mentioned components of the present invention can be obtained commercially.

[0045] Above-mentioned each embodiment of the present invention all can be prepared by following method: its specific method is as follows:

[0046] 1) At room temperature, first dissolve fatty alcohol polyoxyethylene ether in deionized water to make an aqueous solution of fatty alcohol polyoxyethylene ether;

[0047] 2), then dissolve triethanolamine oleic acid soap, triethanolamine, isomeric alcohol polyoxyethylene ether, coconut oil fatty acid diethanolamide, polyoxyethylene ether oleoyl ricinoleate in the aqueous solution of the above step 1), make a mixed solution;

[0048] 3) Dissolve sodium gluconate, dipropylene glycol methyl ether, sodium polyacrylate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com