Cathode copper ultrasonic cleaning groove

An ultrasonic wave and cleaning tank technology, applied in the field of electrolytic copper cleaning tank devices, can solve the problems of large steam loss, high steam consumption, poor hot water fluidity, etc., achieve low cleaning temperature, reduce steam consumption, and solve residual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

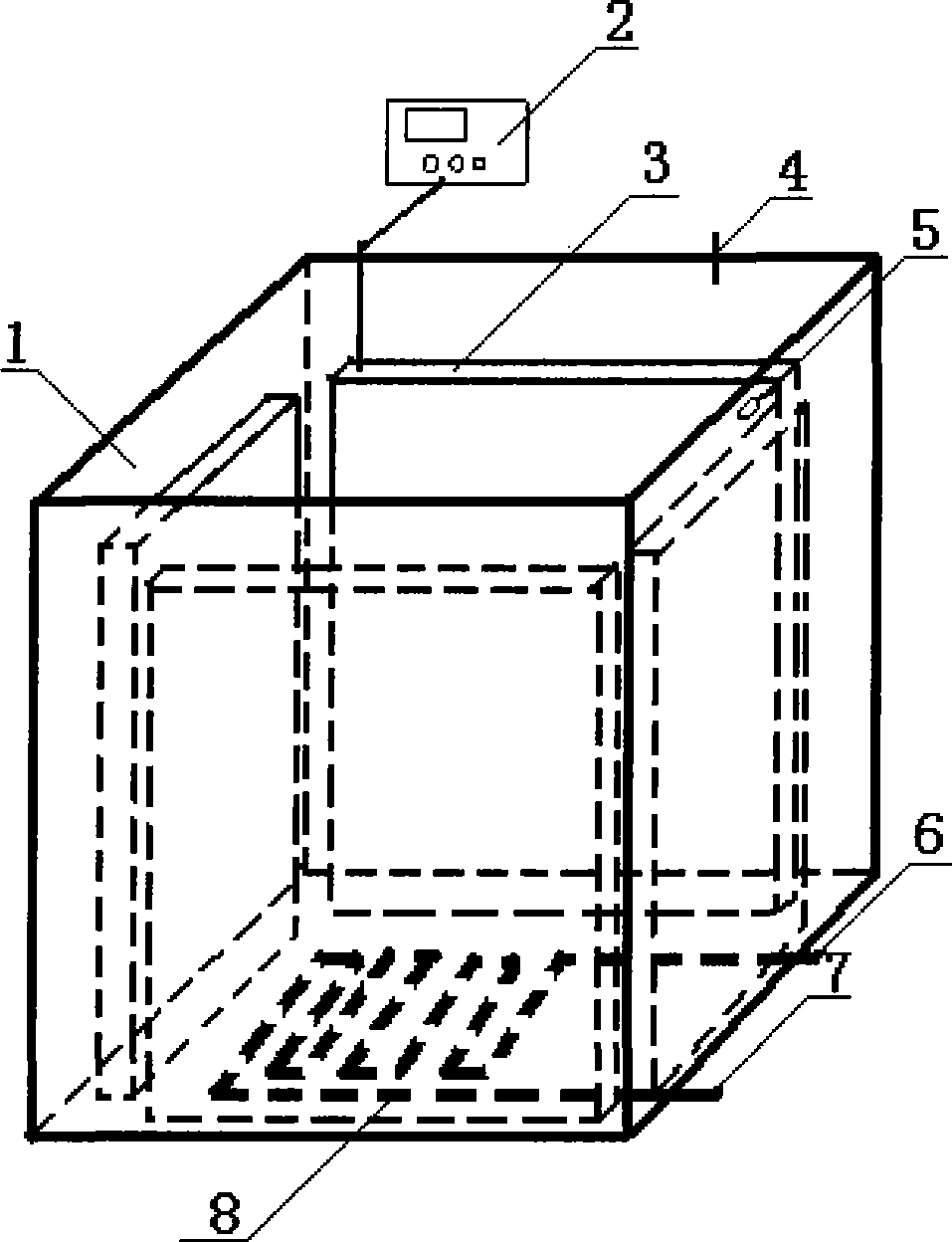

[0009] The cathode copper ultrasonic cleaning tank is mainly composed of a stainless steel cleaning tank 1, an ultrasonic vibrating plate 3, a steam coil 8, and an electric control device 2. An ultrasonic vibrating plate (ultrasonic transducer) 3 is installed on four sides of the stainless steel cleaning tank 1, Add cleaning water through the water inlet pipe 4. There is an overflow port 5 on one side of the stainless steel cleaning tank 1. When the water is full, it overflows from the overflow port 5. A steam coil 8 is installed at the bottom of the stainless steel cleaning tank 1, and steam enters from the steam inlet pipe 6. , the condensed water outlet pipe 7 discharges the condensed water to realize the heating of the cleaning water; after the water is filled and heated to 40-70°C, the cathode copper can be put in, and then the electric control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com