A coke cleaning method using ozone mixed gas

A technology of mixing gas and ozone, which is used in cracking, petroleum industry, non-catalytic thermal cracking and other directions to achieve the effect of reducing energy consumption, low coke cleaning temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

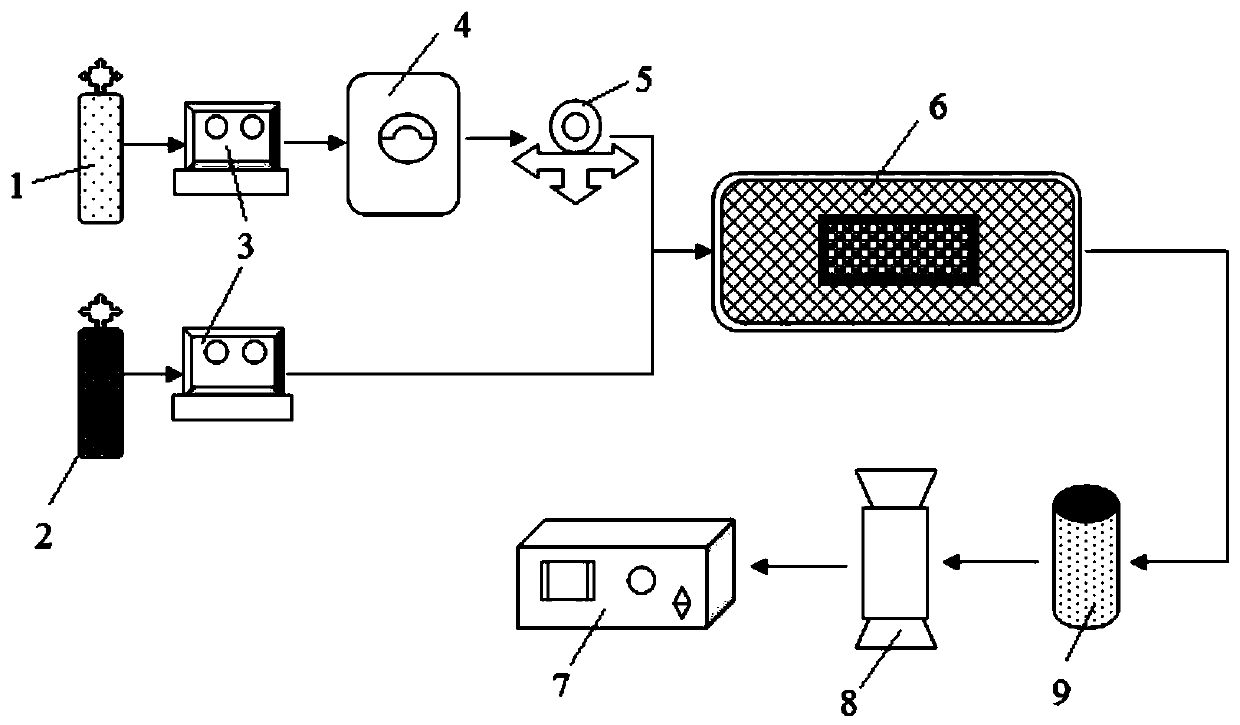

[0033] use figure 1 The device shown uses ozone mixed gas for decoking. Specific steps are as follows:

[0034] A. According to figure 1 Connect the pipeline and put the device with coke on the inner wall into the muffle furnace;

[0035] B. Raise the muffle furnace to the specified temperature of 160°C and keep the temperature constant;

[0036] C. Open N 2 Bottle valve and mass flow meter, regulating N 2 flow makes N 2 The molar percentage that accounts for described ozone mixed gas is 22%;

[0037] D. open O 2 Bottle valve and mass flow meter, regulating O 2 Flow makes O 2 Accounting for the molar percentage of the ozone mixed gas is about 74%;

[0038] E. Open O 3 generator power supply, the O 3 Generate concentration adjusted to 100%;

[0039] F. Open O 3 Concentration detector, monitoring makes O 3 The concentration is 80mg / l;

[0040] G. Open the ozone decomposer, unreacted O 3 break down;

[0041] H. Turn on the infrared detector to monitor the genera...

Embodiment 2

[0045] Among them, the muffle furnace is raised to the specified temperature of 220 ° C and kept at a constant temperature, O 3 The concentration is 60mg / l, N 2 Accounting for the mol percent of the ozone mixed gas is about 26%, O 2 Accounting for the mole percentage of the ozone mixed gas is 71%.

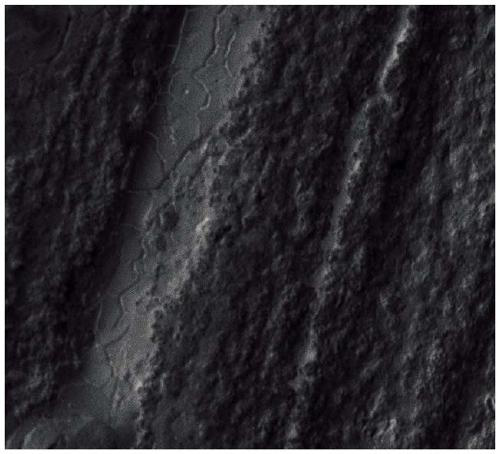

[0046] Other conditions are with embodiment 1. It takes about 60 minutes to complete the coke cleaning. After the coke cleaning is completed, the appearance of the inner wall of the device is as follows: image 3 shown. Depend on image 3 It can be seen that the coke on the inner wall of the device is relatively clean, and the inner wall of the device has a smooth surface and a high degree of integrity.

[0047]The device after decoking in this embodiment is used to continue the oil refining catalytic reaction, and then use the conditions of this embodiment to perform decoking. After repeating this 10 times, the surface of the inner wall of the device is still intact.

Embodiment 3

[0049] Among them, the muffle furnace is raised to the specified temperature of 200 ° C and kept at a constant temperature, O 3 The concentration is 74mg / l, N 2 Accounting for the mol percent of the ozone mixed gas is about 10%, O 2 The mole percentage of the ozone mixed gas is about 86%.

[0050] Other conditions are with embodiment 1. It takes about 50 minutes to complete the coke cleaning. After the coke cleaning is completed, the appearance of the inner wall of the device is as follows: Figure 4 shown. Depend on Figure 4 It can be seen that the coke on the inner wall of the device is relatively clean, and the inner wall of the device has a smooth surface and a high degree of integrity.

[0051] The device after decoking in this embodiment is used to continue the oil refining catalytic reaction, and then use the conditions of this embodiment to perform decoking. After repeating this 10 times, the surface of the inner wall of the device is still intact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com