Cleaning method of esterifying polycondensation step for polyester preparing equipment

A technology of esterification and polycondensation, which is applied in the cleaning field of the esterification and polycondensation process of polyester plants, can solve the problems of high heat load, prolonged start-up time, and poor safety, and achieve low heat load, good cleaning effect, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

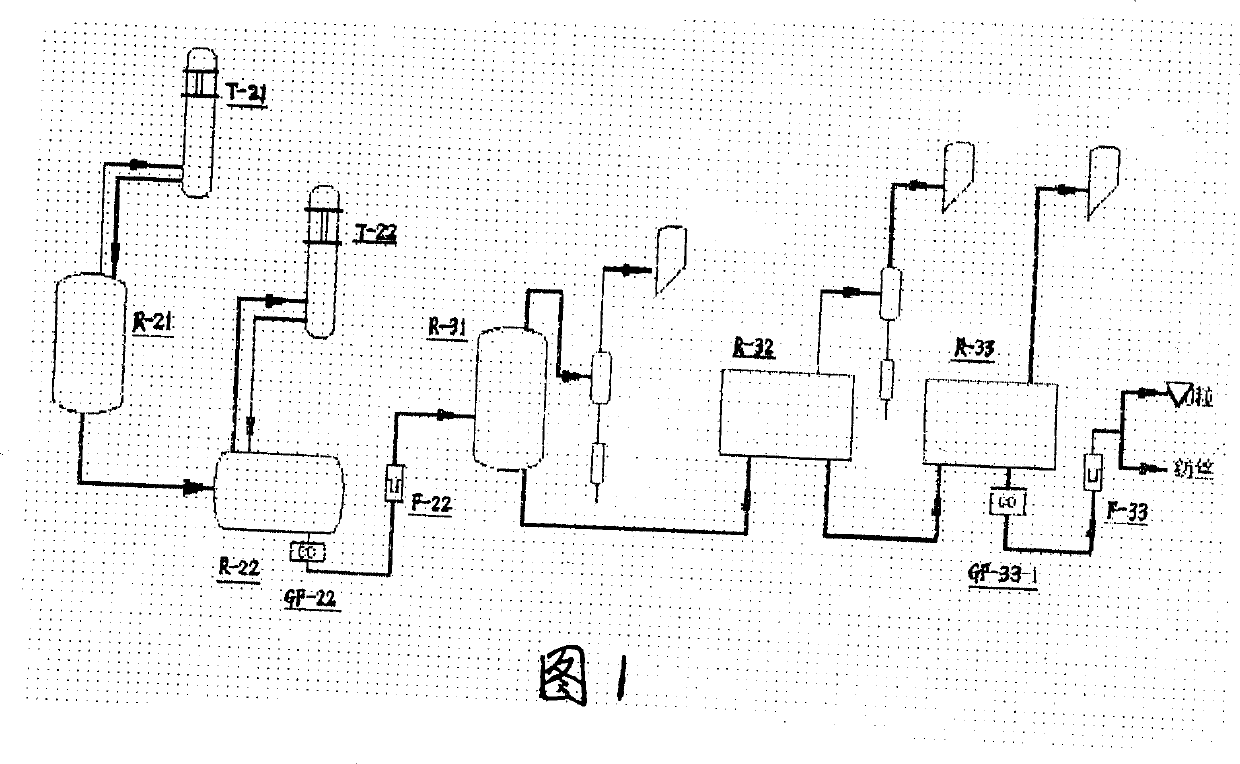

[0008] The names of equipment and chemical substances are:

[0009] R-21 The first esterification tank R-22 The second esterification tank

[0010] R-31 The first polycondensation tank R-32 The second polycondensation tank

[0011] R-33 The third polycondensation tank T-21 The first rectification tower

[0012] T-22 Second Distillation Column F-22 Melt Filter

[0013] F-33 Melt Filter GP-22 Melt Transfer Pump

[0014] GP-33-1 Melt Transfer Pump EG Glycol

[0015] KOH potassium hydroxide TEG triethylene glycol

[0016] 1. Use 1.0% KOH-EG solution for the first cleaning:

[0017] 1. Cool R-21 to 190°C, introduce 14 tons of EG, start the R-21 agitator to stir, add 140 kg of KOH, control the internal pressure of R-21 to 0.14MPa, gradually increase the temperature to 220°C, and keep the cleaning time for 3 hours. T-21 was cleaned with EG steam in R-21.

[0018] After 2.3 hours, R-21 cools down to 190°C, transfers 7.0 tons of cleaning liquid from R-21 to R-22, turns off the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com