Fluorine-free cleaning agent as well as preparation method and application thereof

A cleaning agent and water-based cleaning agent technology, applied in detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve the problems of difficult to remove by-products, long cleaning time, wafer defects, etc., to reduce cleaning High temperature, high cleaning time, and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a preparation method of the above-mentioned fluorine-free cleaning agent, comprising: mixing water, an organic solvent, an amine compound with one or more of corrosion inhibitors, acids and alcohol compounds to obtain a fluorine-free cleaning agent agent.

[0054] The present invention has no special limitation on the sources of all raw materials, which can be commercially available. The water, organic solvents, amine compounds and corrosion inhibitors are all the same as those described above, and will not be repeated here.

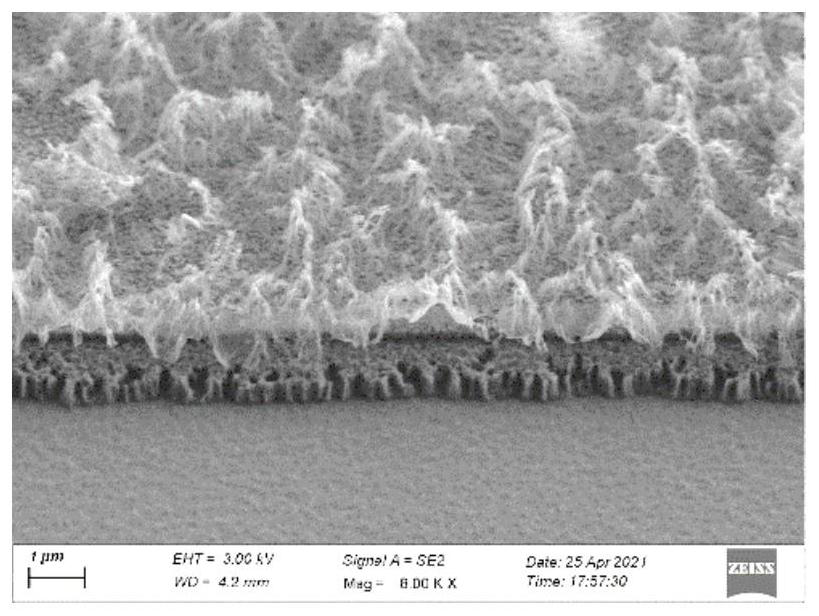

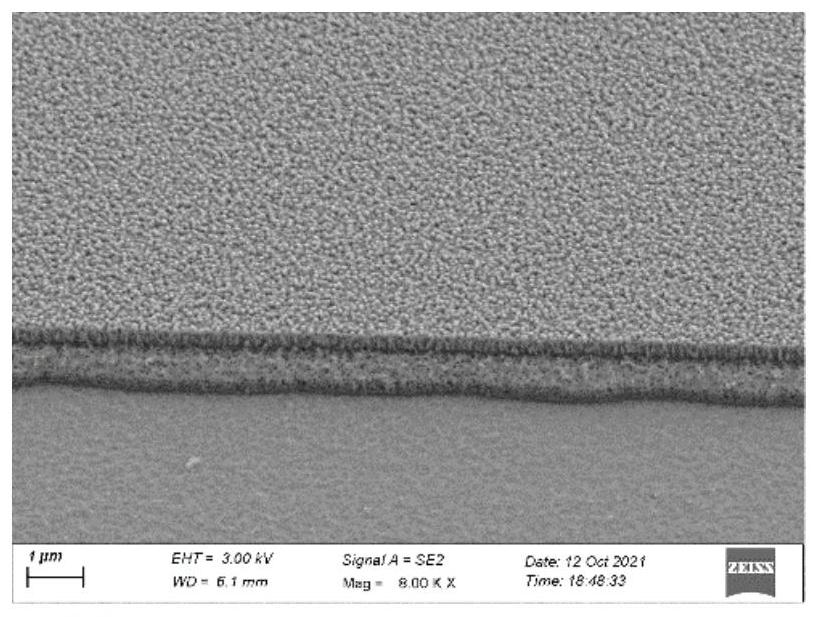

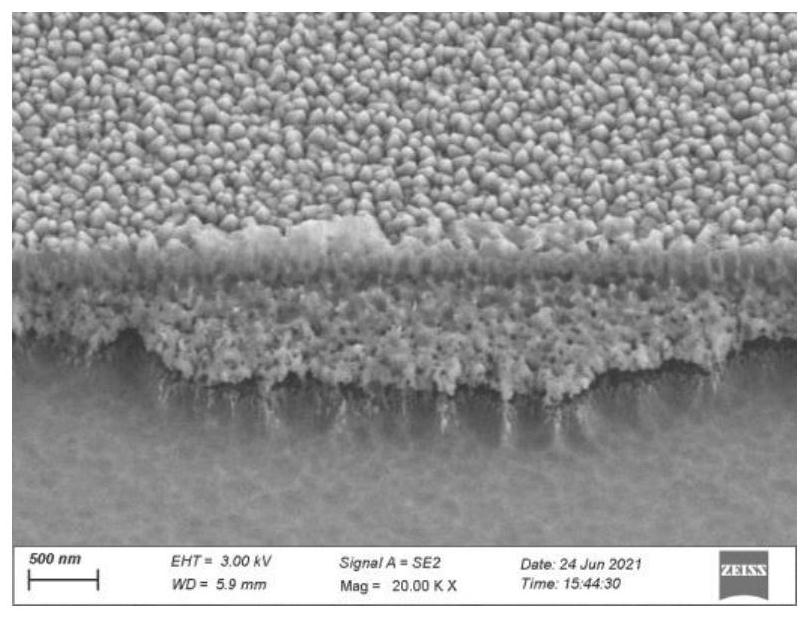

[0055] The present invention also provides a kind of application of the above-mentioned fluorine-free cleaning agent in the integrated circuits including but not limited to the semiconductor field; further preferably, the application in cleaning after the semiconductor etching process; the semiconductor etching process can be metal Etching, dielectric material etching, and etching of inorganic media such as sil...

Embodiment 1

[0063] Containing 15wt% monoethanolamine, 15wt% diethylene glycol monobutyl ether, 1wt% D-sorbitol, 1wt% benzotriazole, 2wt% ethylene glycol and the rest of ultrapure water, the total amount of each chemical reagent is 100g, and add to the beaker one by one and shake well. Among them, the solid reagent can be weighed first, and then dissolved by adding a solvent.

Embodiment 2

[0065]Containing 25wt% monoethanolamine, 15wt% diethylene glycol monobutyl ether, 1wt% D-sorbitol, 1wt% benzotriazole, 2wt% ethylene glycol and the rest of ultrapure water, the total amount of each chemical reagent is 100g, and add to the beaker one by one and shake well. Among them, the solid reagent can be weighed first, and then dissolved by adding a solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com