Lead-free copper slurry applied to silicon solar battery electrode and preparation method thereof

A silicon solar cell and lead-copper technology, applied in the field of solar cells, can solve the problems of increased production costs, lower application safety factors, lower silver paste prices, etc., and achieve the effects of reducing microcracks, reducing series resistance, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mixed copper powder is prepared using the following three types of copper powder:

[0033] The particle size distribution of spherical copper powder A is 0.5-2μm, the particle size distribution of flake copper powder B is 1-3μm, and the particle size distribution of spherical copper powder C is 4-7μm. The mixed copper powder adopts various mixing ratios. For specific mixing ratios, see Table 1.

[0034] Table-1 Mixing ratio of mixed copper powder

[0035] Mixed Copper Powder No.

Cu1#

Cu2#

Cu3#

Cu4#

[0036] Copper powder A(wt%)

63.6

61.5

66.7

58.3

Copper powder B(wt%)

27.3

30.8

25.0

33.3

Copper powder C(wt%)

9.1

7.7

8.3

8.4

A:B:C mixing ratio

7∶3∶1

8∶4∶1

8∶3∶1

7∶4∶1

[0037] Accurately weigh copper powder A, copper powder B, and copper powder C according to the ratio in Table-1, and mix them in a mixer for...

Embodiment 2

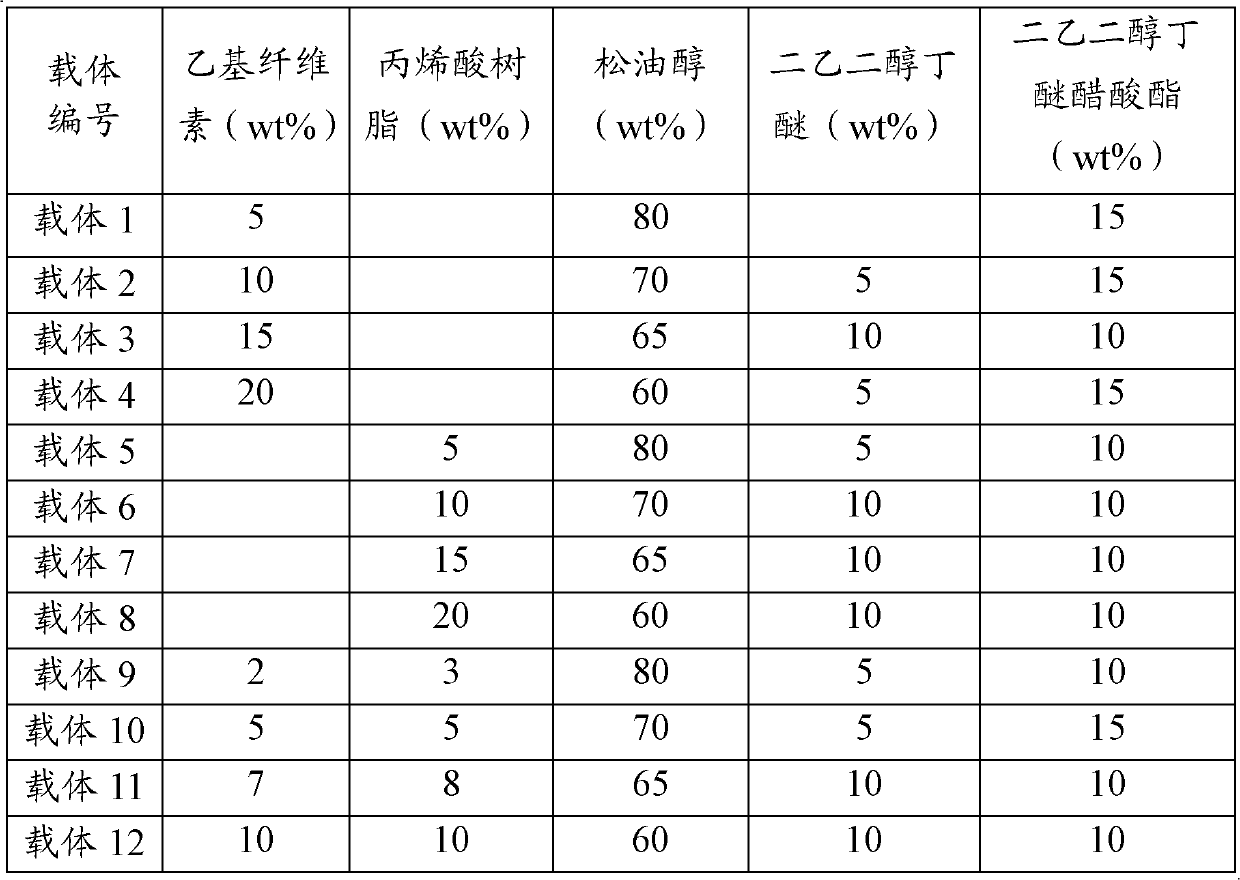

[0040] Highly thixotropic organic vehicles can produce various viscosities according to the proportion of their materials. Different viscosities are suitable for different environments. Organic vehicles with a large proportion of ethyl cellulose and acrylic resin have high viscosity and are suitable for use in summer. On the contrary, the viscosity is small, which is suitable for use in winter. The ratio of each component of the high thixotropic organic carrier related to the present invention is shown in Table-2.

[0041] Table-2 The ratio of each component of the relevant high thixotropic organic vehicle

[0042]

[0043] The preparation process of the organic carrier: accurately weigh various materials according to the above ratio, place them in a stainless steel container, heat them with an oil bath heating device, and heat them at 80°C to 100°C with heat preservation and stirring until the heat preservation and stirring are completed, and then cool to After room temper...

Embodiment 3

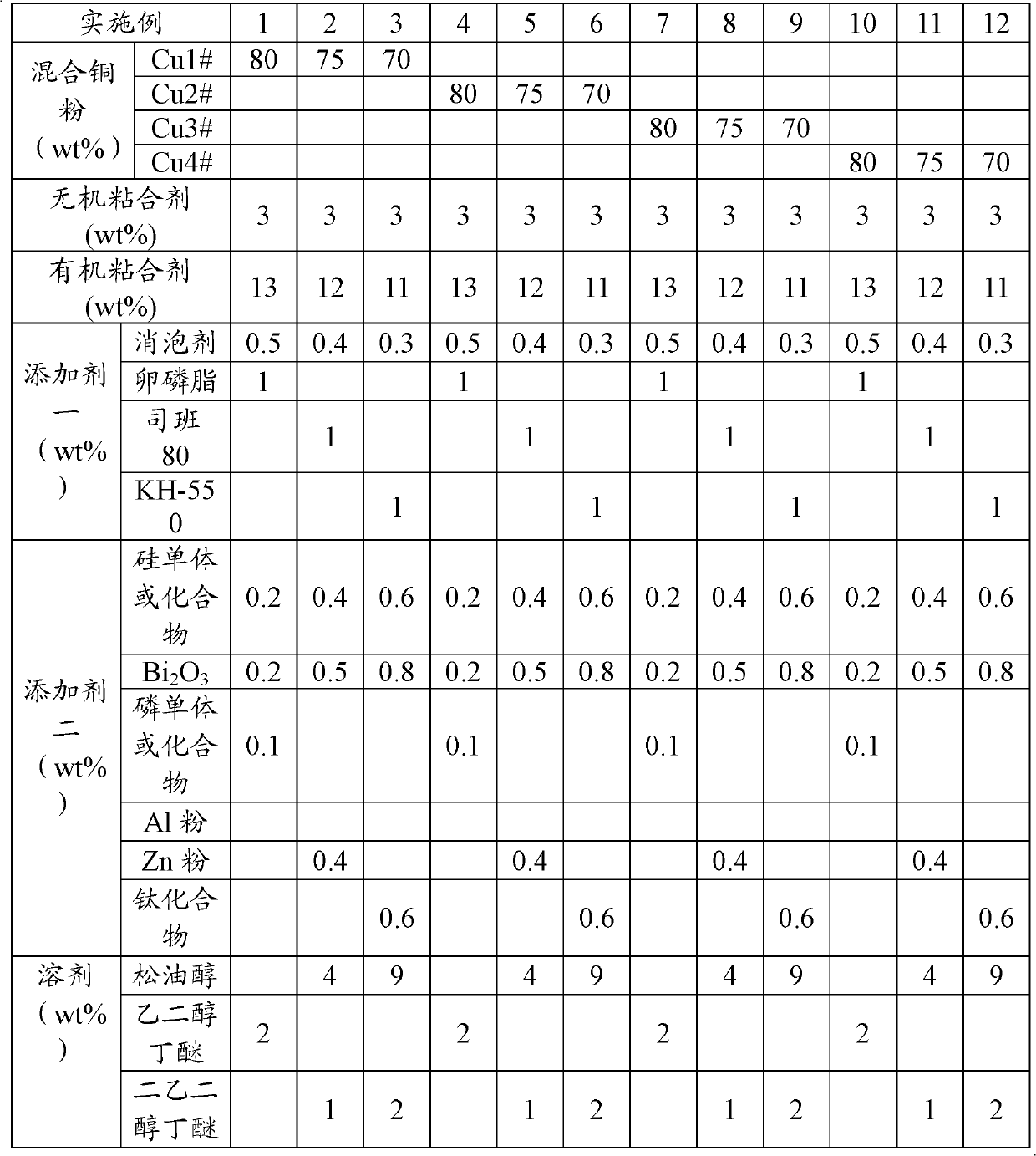

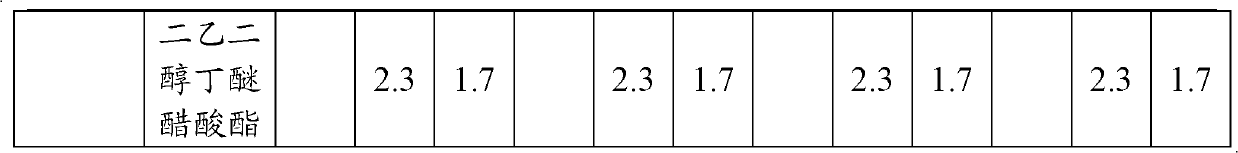

[0045] Examples of preparation of lead-free copper paste for silicon solar cell electrodes, the proportions are shown in Table-3 and Table-4.

[0046] Table-3 Examples of preparation of lead-free copper paste for silicon solar cell electrodes

[0047]

[0048]

[0049] Table-4 Examples of preparation of lead-free copper paste for silicon solar cell electrodes (continued table)

[0050]

[0051] Accurately weigh the above-mentioned various materials, carry out strict mixing and grinding, and carry out thorough dispersion and rolling, and finally produce a paste-like liquid with uniform color, and the production is completed.

[0052] Print the finished lead-free copper paste on the silicon solar cell substrate with a 200-325 mesh stainless steel screen, place it flat at room temperature for 10-15 minutes, dry it at 130-160°C for 10-15 minutes, and then place it in a tunnel-type nitrogen-protected conveyor belt furnace Medium sintering, peak temperature 800°C, peak hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com