High-organic-content dredged silt composite curing material

A technology of organic matter content and dredging sludge, applied in fixed/solidified sludge treatment, sludge treatment, solid waste management, etc., can solve problems such as affecting biological growth, easily polluting the surrounding environment, endangering human health, etc. Low content, good for sustainable development, high strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

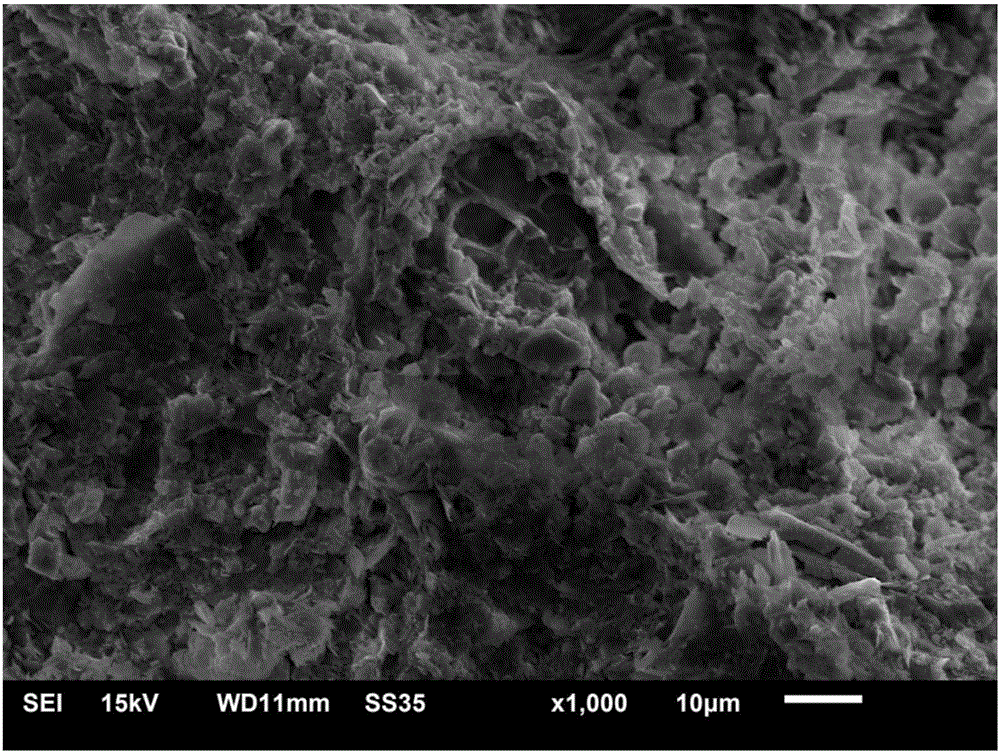

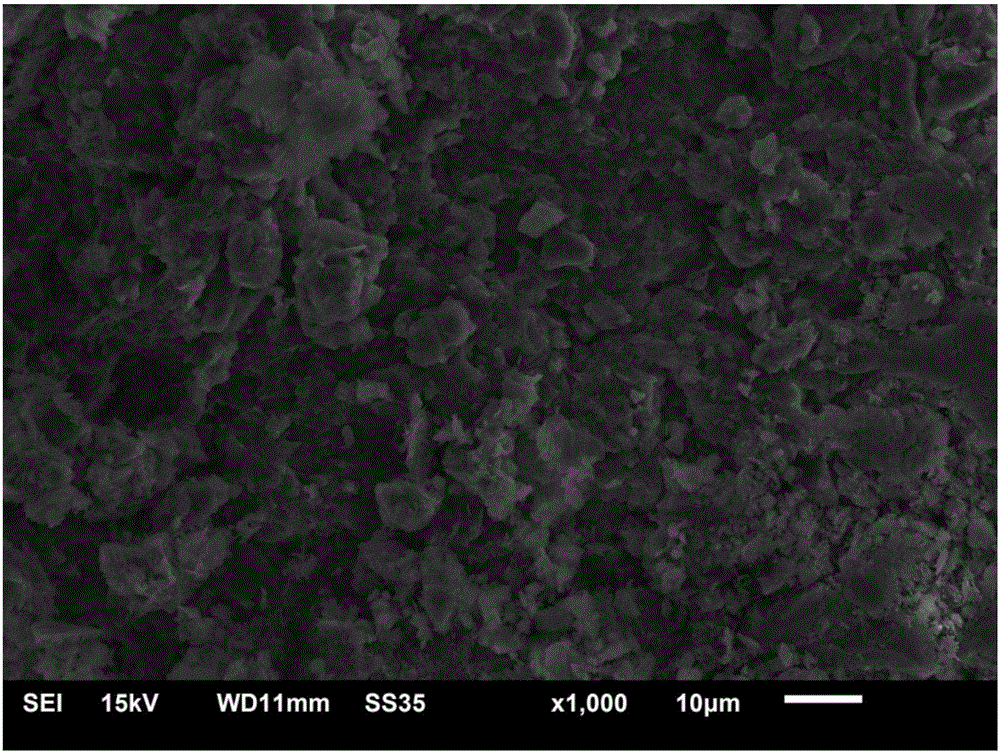

[0041] The mixing ratio of high organic matter content dredging silt composite curing material in the present embodiment is: cement 6%, fly ash 5%, slag 4%, lime 4%, phosphogypsum 3%, exciter 2%, put silt, curing agent Mix well in a mixing pot and stir for 5 minutes. For discharging, the mixed cured material is pressed into shape by a testing machine, and a cylindrical sample with a size of Φ50*50mm is prepared. Standard curing and performance test results are shown in Table 1. figure 1 It is the SEM image of the dredged silt hardened body before solidification treatment. It can be seen that the structure of the dredged silt hardened body is loose; figure 2 It is the SEM image of the dredged silt solidified soil after curing in this embodiment. It can be seen that the solidified soil has a relatively dense structure after solidification treatment.

Embodiment 2

[0043]In the present embodiment, the mixing ratio of dredging silt composite curing material with high organic matter content is: 9% cement, 7.5% fly ash, 6% slag, 6% lime, 5% phosphogypsum, and 4% activator. Mix well in a mixing pot and stir for 5 minutes. For discharging, the mixed cured material is pressed into shape by a testing machine, and a cylindrical sample with a size of Φ50*50mm is prepared. Standard curing and performance test results are shown in Table 1.

Embodiment 3

[0045] The mixing ratio of high organic content dredging silt composite curing material in the present embodiment is: cement 6%, fly ash 5%, slag 4%, lime 4%, phosphogypsum 3%, activator 2%, potassium persulfate 0.8%, Put the sludge and curing agent in a mixing pot and mix evenly, and stir for 5 minutes. For discharging, the mixed cured material is pressed into shape by a testing machine, and a cylindrical sample with a size of Φ50*50mm is prepared. Standard curing and performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com