Waste drilling mud treatment process

A treatment process and waste mud technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve high moisture content of sediment, residual flocs, poor flocculation effect Good and other problems, to achieve the effect of low water content and good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

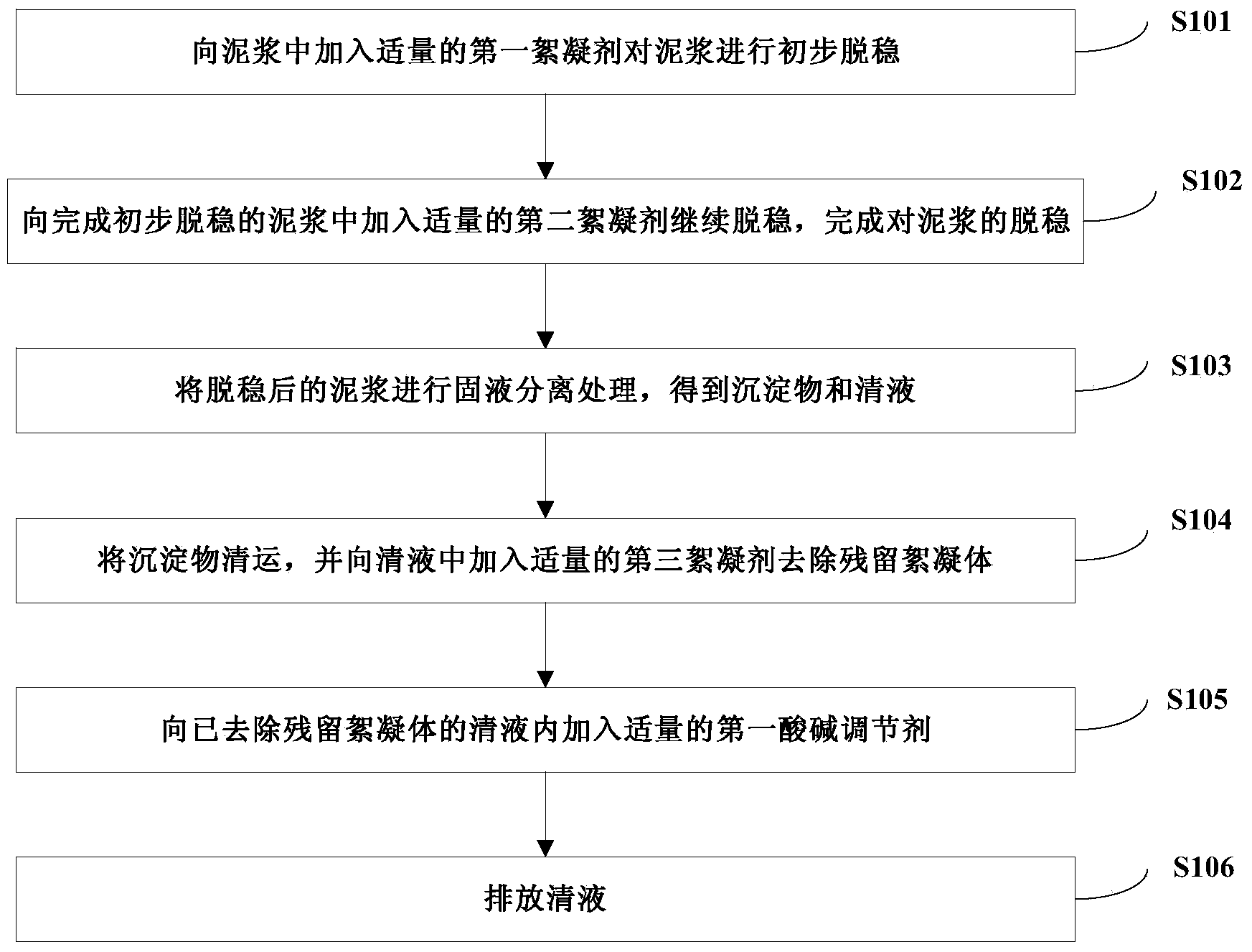

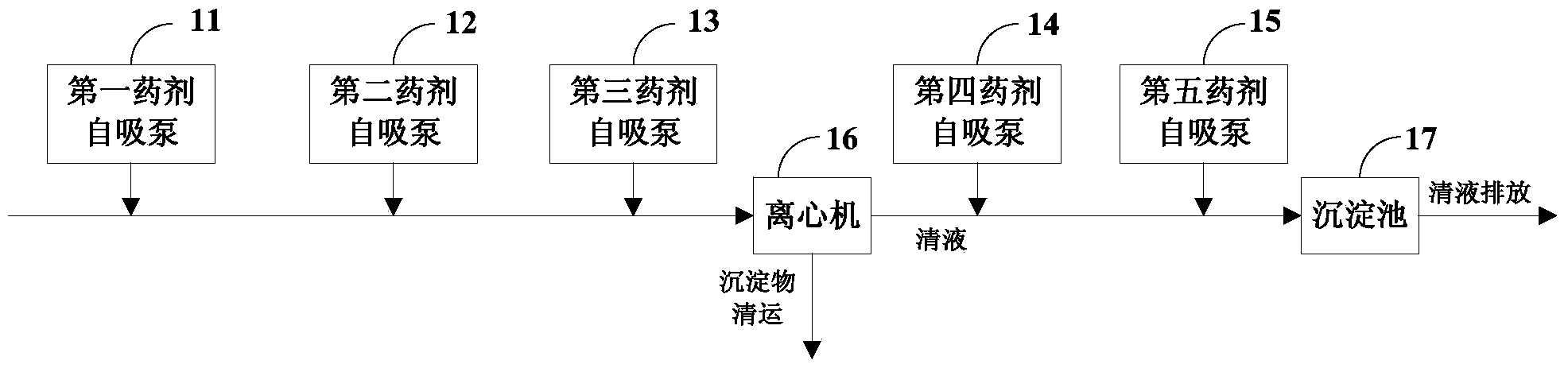

[0017] There are many traditional mud treatment methods. Among them, the chemical flocculation treatment method is to separate the solid and liquid of the mud by adding chemicals to the mud, so as to facilitate the subsequent processing of the separated sediment and clear liquid respectively, so that both All meet the standard of reuse, which is the treatment method that contributes the most to the environment among all mud treatment methods. Therefore, in order to solve the technical problems existing in the traditional chemical flocculation method, the embodiments of the present invention provide the following technical solutions.

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com