Method for simultaneously desulfurizing, denitrating and purifying flue gas

A technology for desulfurization, denitrification, and smoke flue gas, which is applied in the field of flue gas purification, can solve problems such as poor desulfurization and denitrification effects, harsh reaction conditions, complex process technology, etc., and achieve low operation and maintenance costs, strong flue gas adaptability, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

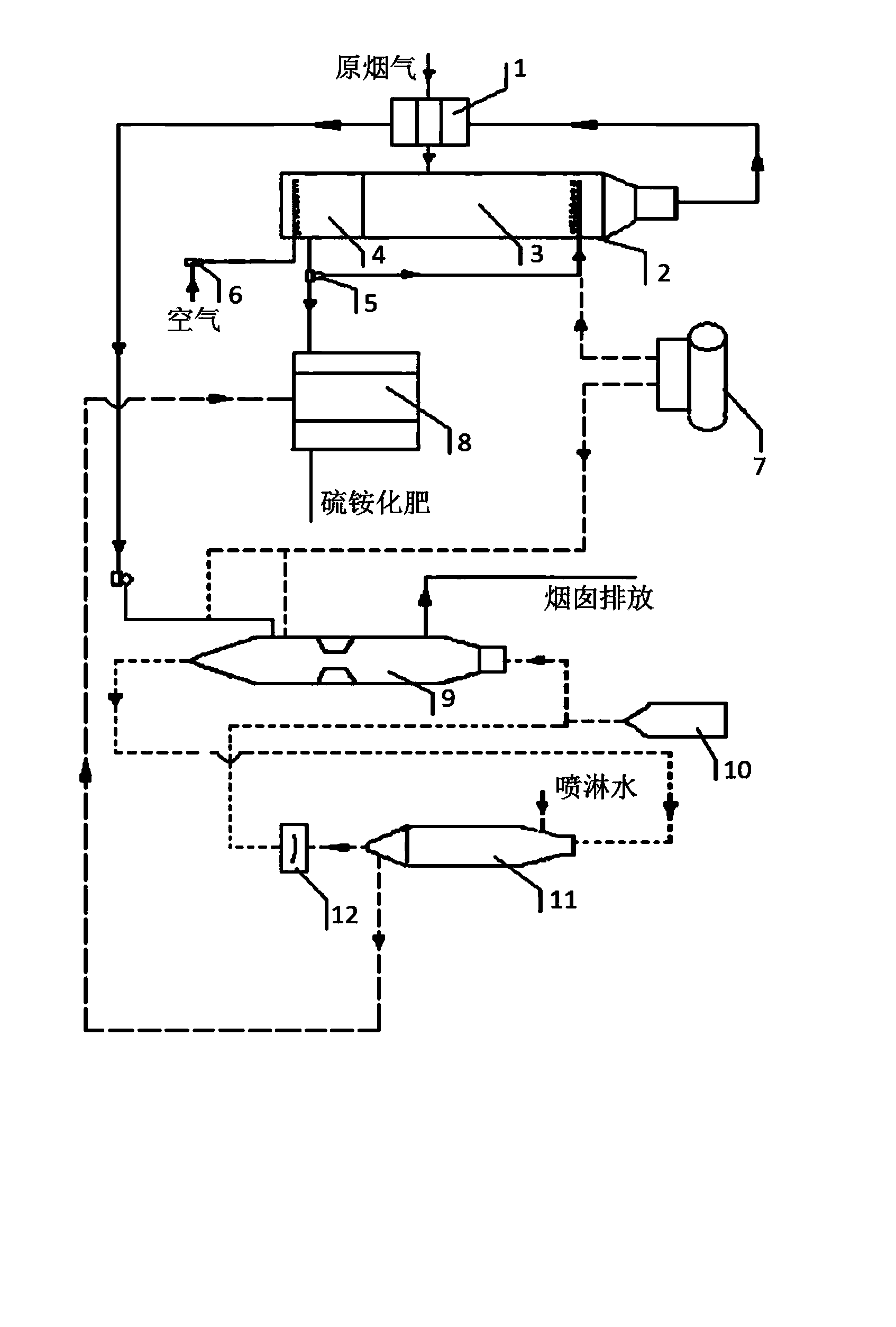

[0030] The flue gas containing sulfur and nitric acid at 1100°C is absorbed by ammonia and desulfurized flue gas is exchanged in the flue gas heat exchanger 1 and cooled to 90°C, then enters the ammonia absorption tower 2, and is sprayed by the upper part of the spray scrubber 3. The ammonium sulfate solution added with ammonia water is contacted, and the dust in the flue gas is washed away by spray washing. During this process, the flue gas is cooled due to adiabatic evaporation, and the SO in the flue gas 2 It is absorbed by the absorption liquid sent by the absorption liquid circulation pump 5. The absorption liquid falls into the aeration oxidizer 4 through the return pipe, and the air is aerated by the blower pump 6 to oxidize the nitrite (ammonium sulfite and ammonium bisulfite) solution into ammonium sulfate solution, and the absorption liquid circulation pump 5 After pressurization, it is sent to the spray washer 3 spray device, and the spraying and absorption are cont...

Embodiment 2

[0034] The flue gas containing sulfur and nitric acid at 200°C is absorbed by ammonia and the desulfurized flue gas is heat-exchanged in the flue gas heat exchanger 1 and cooled to 50°C, then enters the ammonia absorption tower 2, and is sprayed by the upper part of the spray absorber 3 The ammonia solution is sprayed and washed to wash away the dust in the flue gas and perform desulfurization. The desulfurized solution is aerated and oxidized by air in the aeration oxidizer 4 to generate ammonium sulfate solution, and then the ammonium sulfate fertilizer is produced after settling, filtering and concentrating tank 8; the desulfurized flue gas is heated to 120°C through the flue gas heat exchanger 1 , according to NO in flue gasX Spray a small amount of ammonia water into the pipeline to control the NH in the flue gas 3 / NOx molar ratio is 0.8, enters the lower part of activated carbon absorption tower 9, and the flue gas passes through adding CuO and V 2 o 5 The activated c...

Embodiment 3

[0037] A certain mercury-containing metallurgical flue gas at 900°C is absorbed by ammonia, then the desulfurized flue gas is exchanged in the flue gas heat exchanger 1 and cooled to 75°C, then enters the ammonia absorption tower 2, and is sprayed by the upper part of the spray scrubber 3. The ammonium sulfate solution with ammonia water is contacted, and the dust in the flue gas is washed away by spray washing. During this process, the flue gas is cooled due to adiabatic evaporation, and the SO in the flue gas 2 It is absorbed by the absorption liquid sent by the absorption liquid circulation pump 5. The absorption liquid falls into the aeration oxidizer 4 through the return pipe, and the air is aerated by the blower pump 6 to oxidize the nitrite (ammonium sulfite and ammonium bisulfite) solution into ammonium sulfate solution, and the absorption liquid circulation pump 5 After pressurization, it is sent to the spray device of the spray scrubber 3, and the spraying and absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com