Simultaneously desulfurization and denitration wet ammonia flue gas cleaning technology and system thereof

A desulfurization and denitrification, flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation and other directions, can solve the problems of increased resistance of desulfurization and denitrification equipment, bulky desulfurization and denitrification equipment, and high construction and operating costs, and achieves the realization of Harmless and resource utilization, overcoming the effects of low denitrification efficiency and high absorbent utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

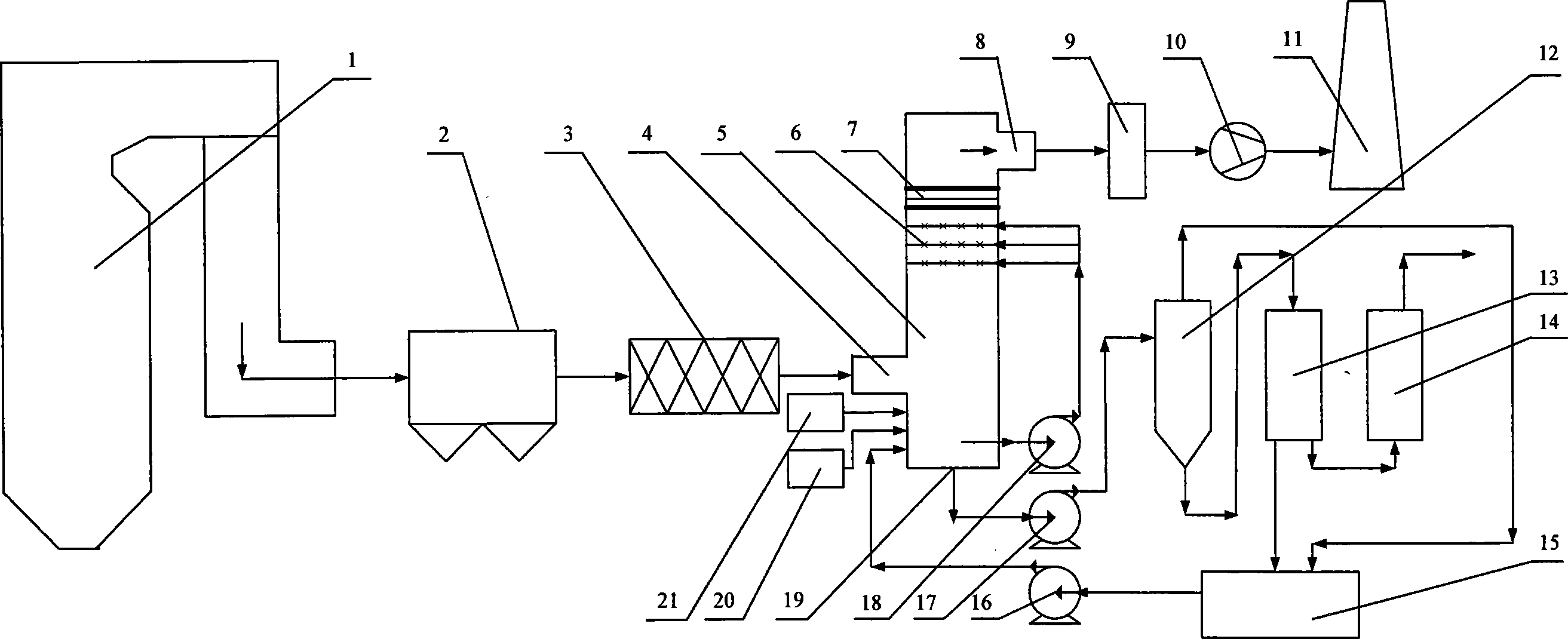

[0030] Below for a coal-fired power station boiler unit, the present invention will be further described in detail in conjunction with the accompanying drawings:

[0031] The wet ammonia flue gas cleaning system with simultaneous desulfurization and denitrification shown in the figure includes a pre-dust removal device 2 arranged on the outlet flue of the coal-fired boiler unit 1 and a desulfurization and denitrification tower 5 for the flue gas reaction main device. The pre-dust removal device 2 adopts an electrostatic precipitator with a wire-plate four-stage electric field structure, which can collect more than 99.5% of dust particles in the flue gas. A hydrogen peroxide or ozone injection device 3 is arranged on the flue between the pre-dust removal device 2 and the desulfurization and denitrification tower 5. This device can be an atomizing injector with a grid structure. This atomizing injector generally includes 1 to 5 One main pipe, 4 to 10 branch pipes are arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com