Precise cotton blending machine

A cotton dispensing machine, precise technology, applied in textiles and papermaking, fiber processing, fiber feeding, etc., can solve problems such as interference transmission speed, achieve the effect of reducing interference, avoiding vibration interference, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. If there is no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the drawings and in conjunction with the embodiments, and the technical solutions of the prior art are omitted here.

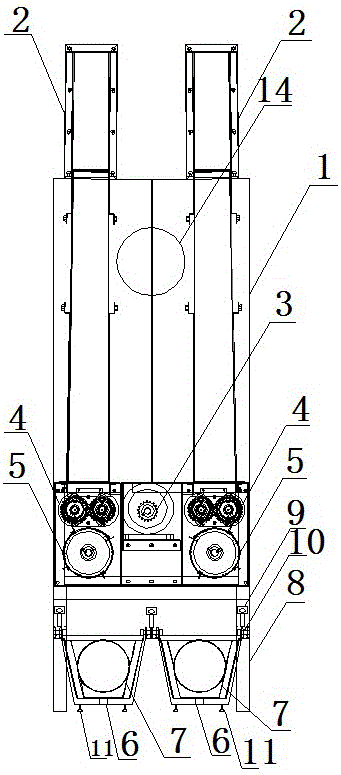

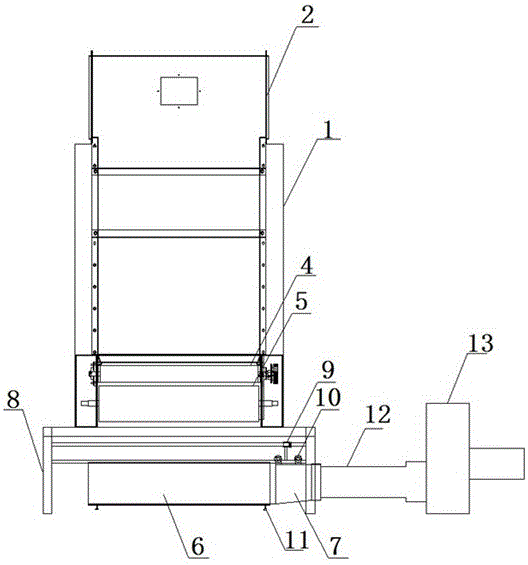

[0019] A precise cotton distributing machine, including a closed shell 1, a cotton inlet channel 2, a driving motor 3, a cotton pressing roller 4, a cotton stripping roller 5, a cotton storage box 6, a suction hopper 7, a bracket 8, a connecting pipe 12 and a fan 13 The closed casing 1 is fixed on the bracket 8, the upper end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com