Mark welding system

A welding system and marking technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as low work efficiency, wrong nameplate hanging, heavy repetitive workload, etc., to avoid vibration interference, ensure stable work, The effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will describe in detail with reference to the drawings in the embodiments of the present invention.

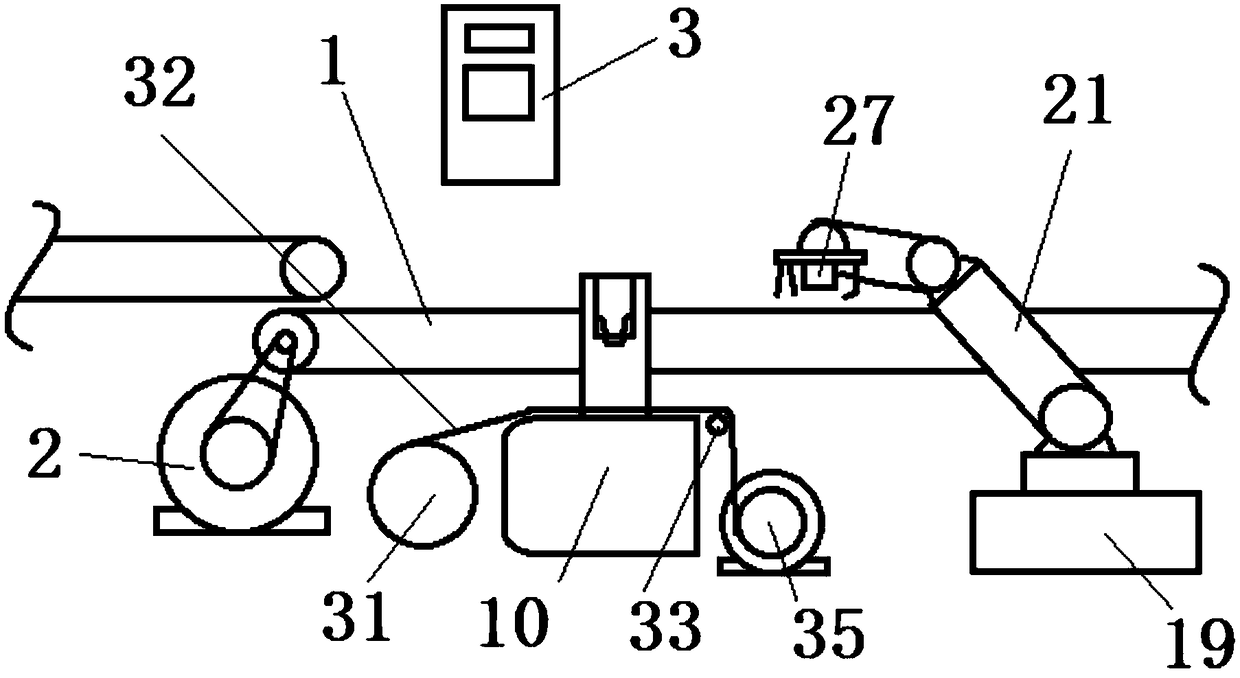

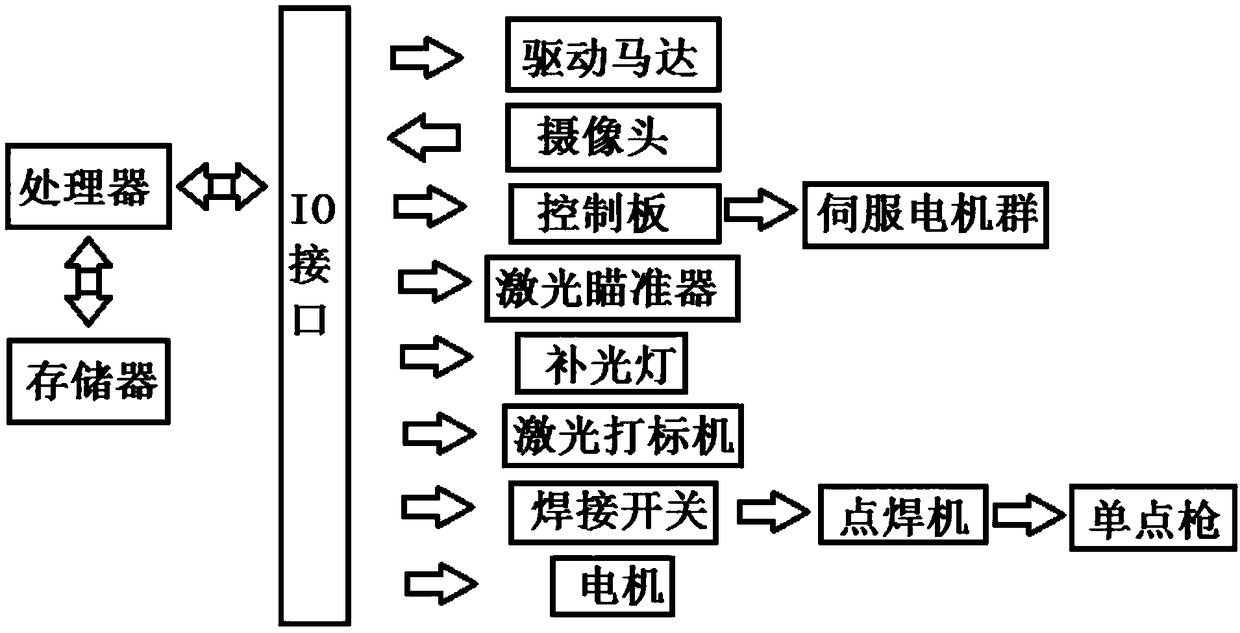

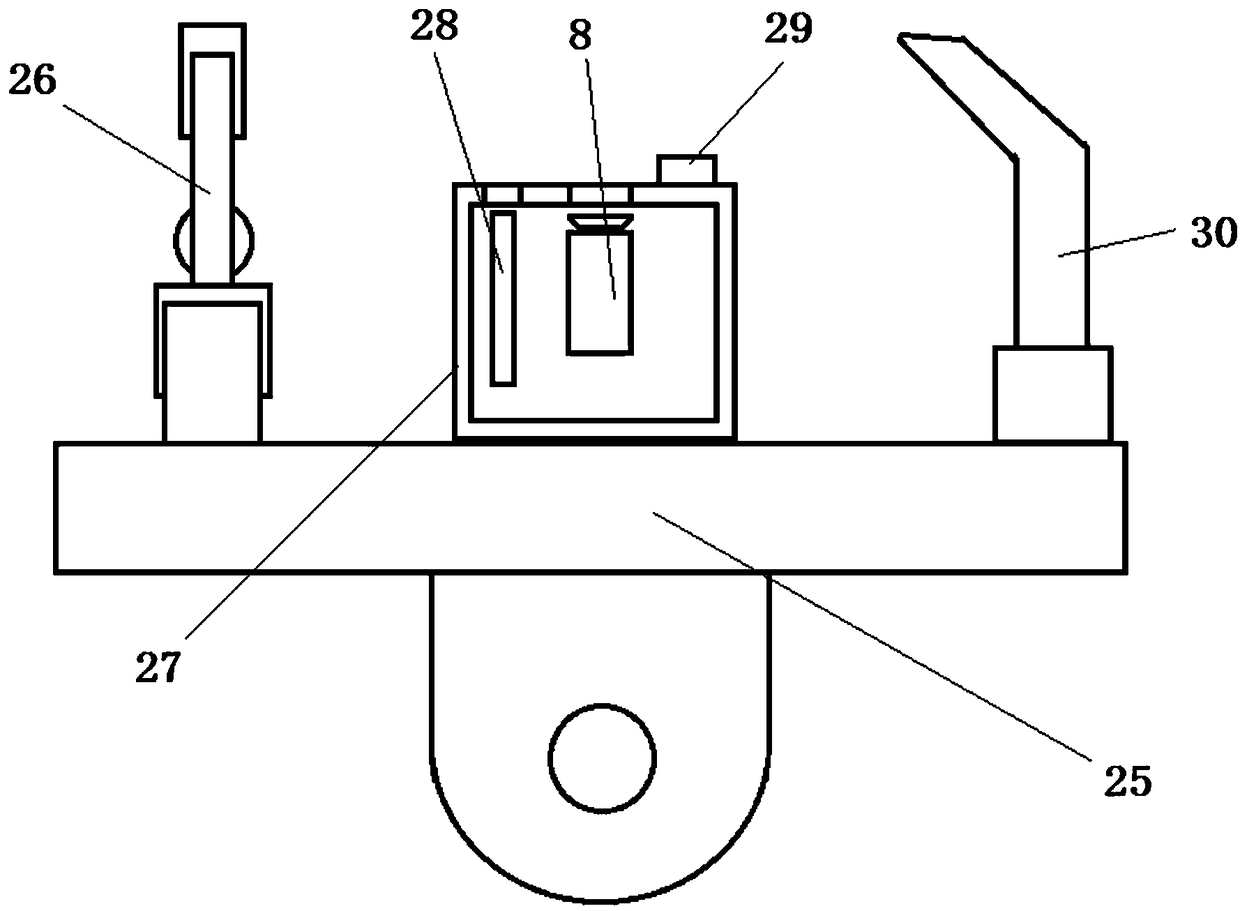

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 8 , a marking welding system, mainly includes: a belt conveyor 1, the feed end of the belt conveyor 1 is located below the discharge port of the production line, and the belt conveyor 1 is provided with a drive for driving the conveyor belt to carry out the transmission work in the horizontal direction Motor 2, wherein the drive motor 2 can be a three-phase motor with the model "YE2-80L-2"; the main control box 3 is fixed on any side of the belt conveyor 1, and the main control box 3 There is a processor, and the processor is connected with a memory and an IO interface. In order to be compatible with the above requirements, it can use a tower server with the model "DELL T630"; the memory is used to store a variety of product reference images and nameplates corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com