Detection device of contact stress distribution

A distributed detection and contact stress technology, applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of detection objects, accuracy, real-time, convenience limitations, etc., to avoid vibration interference, simple structure, good combination performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

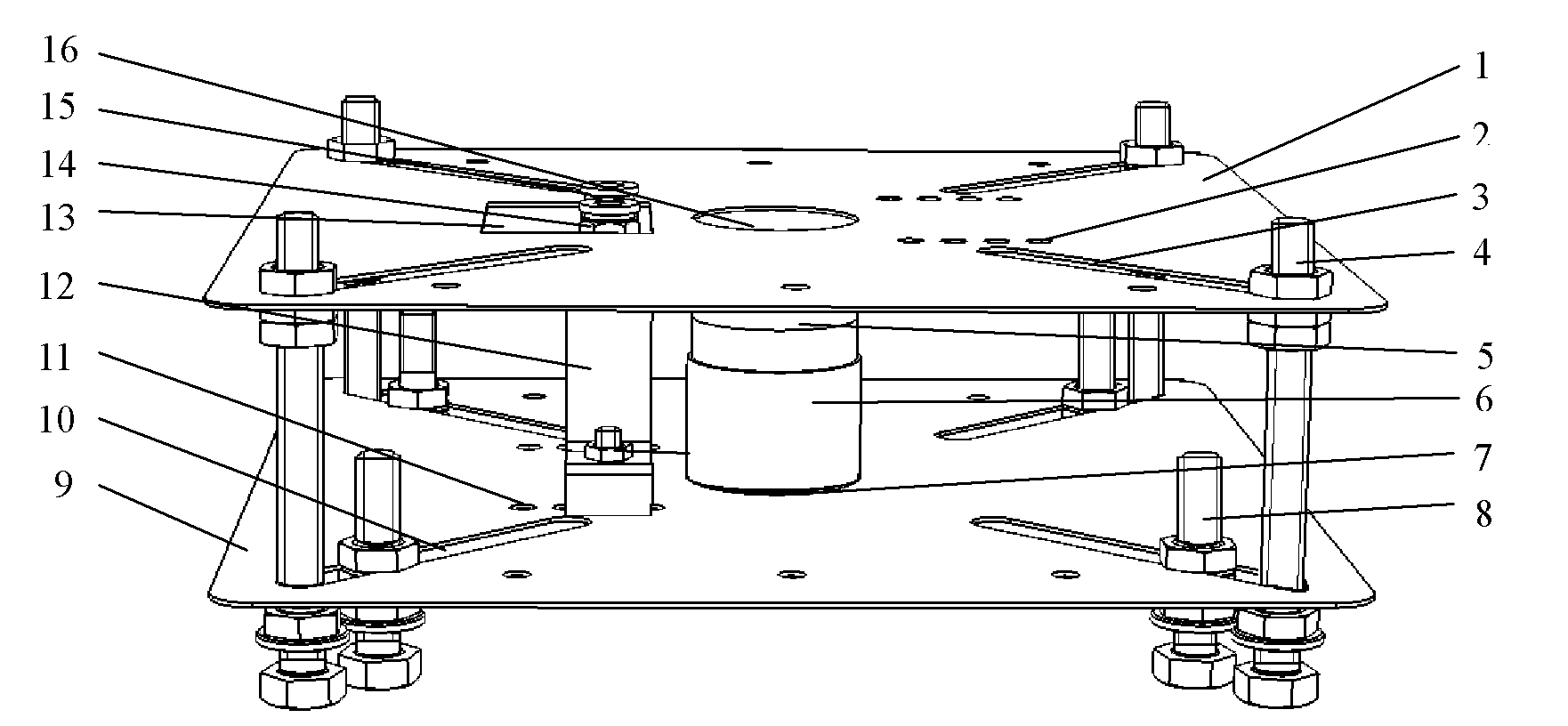

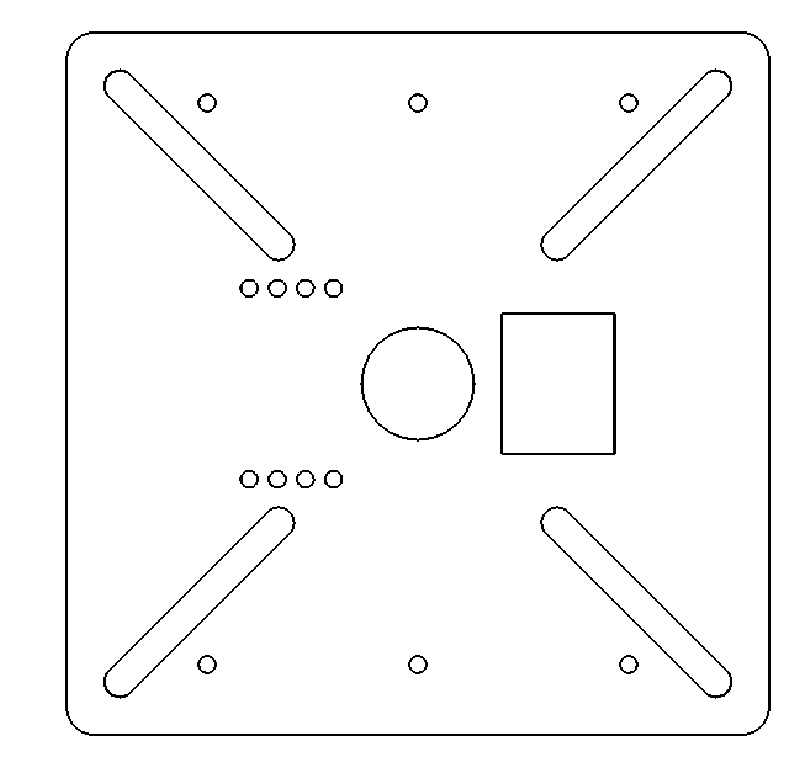

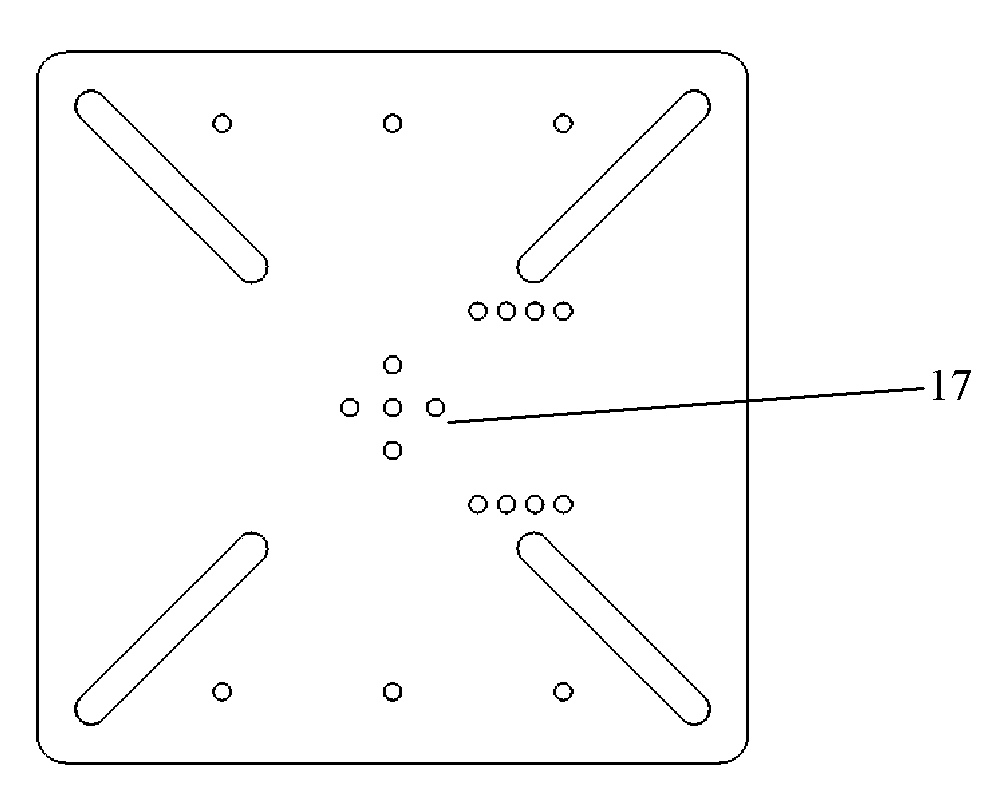

[0021] refer to Figure 1-4 , a contact stress distribution detection device, including an upper workbench 1, a lower workbench 9, a pneumatic vibrator 12 and a spherical indenter module, and the upper workbench 1 and the lower workbench 9 are provided with diagonal strip grooves 3, 10, connected and fixed by fixing bolts 4, 8, the upper workbench 1 and the lower workbench 9 are provided with inline array holes 2, 11 for installing the pneumatic vibrator 12, and the upper workbench 1 A circular hole 16 for installing a plane sample is opened at the position facing the spherical indenter module; the spherical indenter module includes a spherical indenter 5, and the spherical indenter 5 is installed on the upper end of the holder 6 and connected to the plane sample. In contact, the lower end of the cage 6 is attached with a pressure sensor 7 for measuring the vibration pressure of the spherical indenter module and is vertically installed on the cross-shaped array hole 17 of the ...

Embodiment 2

[0029] The difference between this embodiment and the first embodiment is that the pneumatic vibrator 12 is installed on the in-line array hole 2 of the upper worktable 1 . The rest of the structures and functions are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com