Vertical lathe

A vertical lathe and turntable technology, applied in lathes and vertical lathes. field, to achieve the effect of improving processing accuracy, reducing working noise, and being easy to process and manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

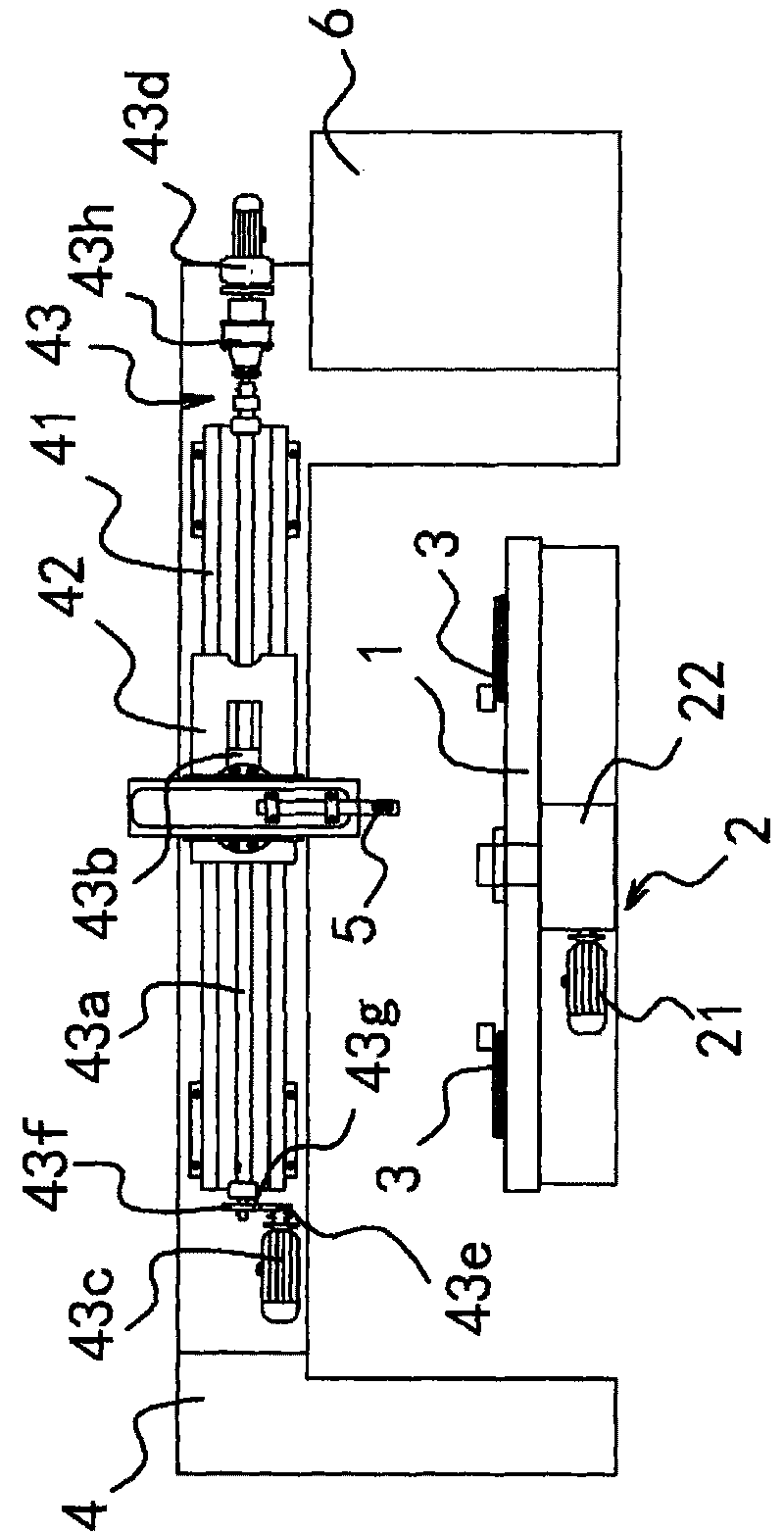

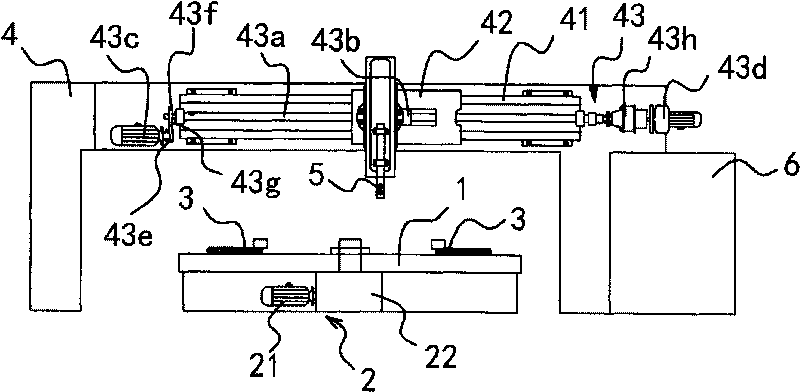

[0018] Such as figure 1 As shown, the vertical lathe includes a turntable 1 arranged horizontally, a power mechanism 2 connected to the turntable 1 and capable of driving the turntable 1 to rotate, and a clamp 3 for fixing workpieces is arranged on the turntable 1 . There are several clamps 3 and they are evenly distributed on the turntable 1, and the number of clamps 3 in this embodiment is four. The power mechanism 2 includes a motor 21 and a reduction box 22 , the input end of the reduction box 22 is connected with the motor 21 , and the output end is connected with the turntable 1 .

[0019] The lathe also includes an independently set knife rest 4, and the knife rest 4 is formed by pouring cement. A tool 5 capable of processing a workpiece is mounted on the tool rest 4 when the turntable 1 rotates. A guide rail 41 arranged horizontally is fixed on the knife rest 4 , and a horizontal sliding seat 42 capable of sliding horizontally along the guide rail 41 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com