Automatic plate milling machine

A trigger, automatic technology, applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., to achieve the effect of improving strength, improving labor efficiency, and being easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

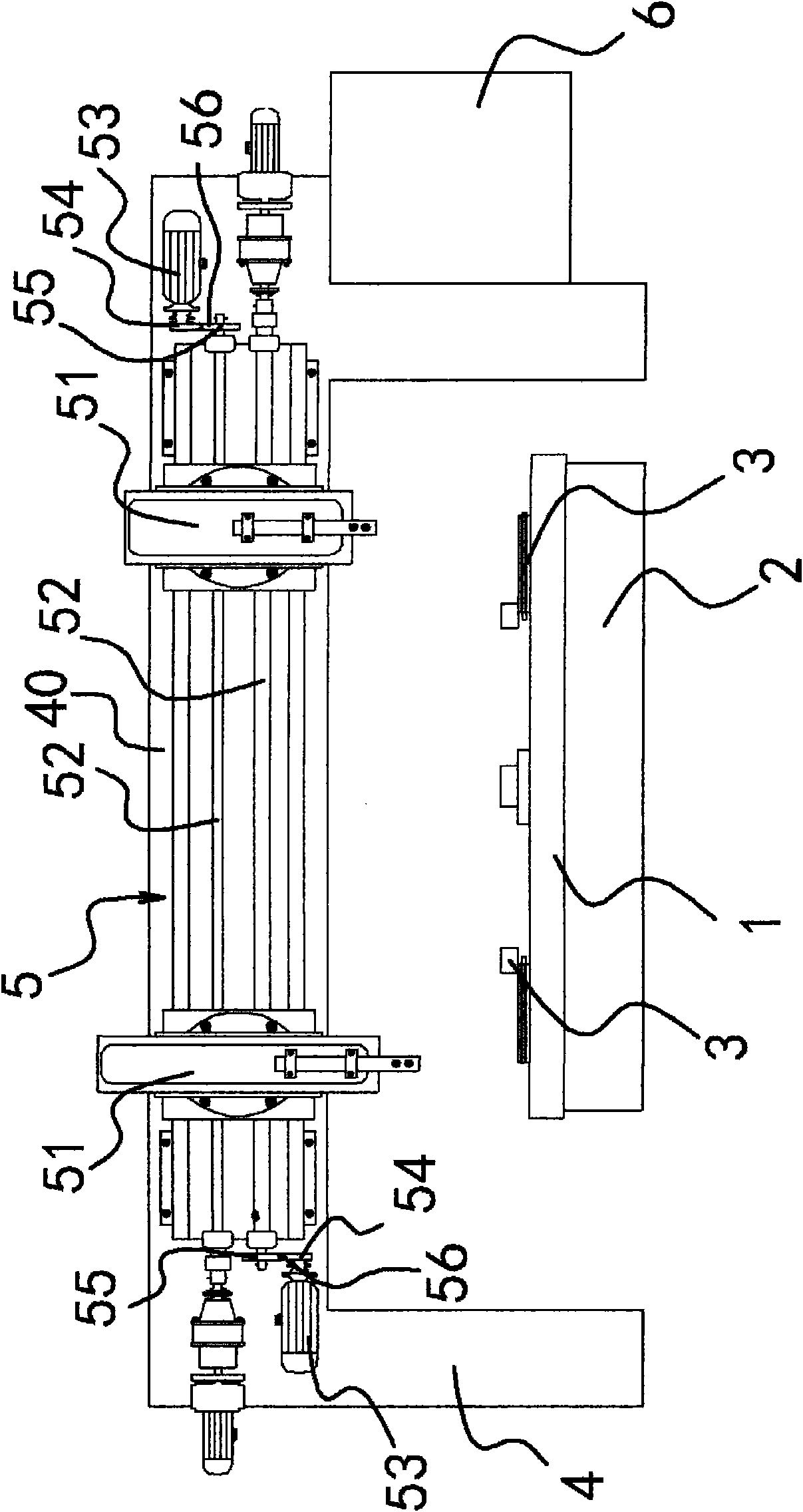

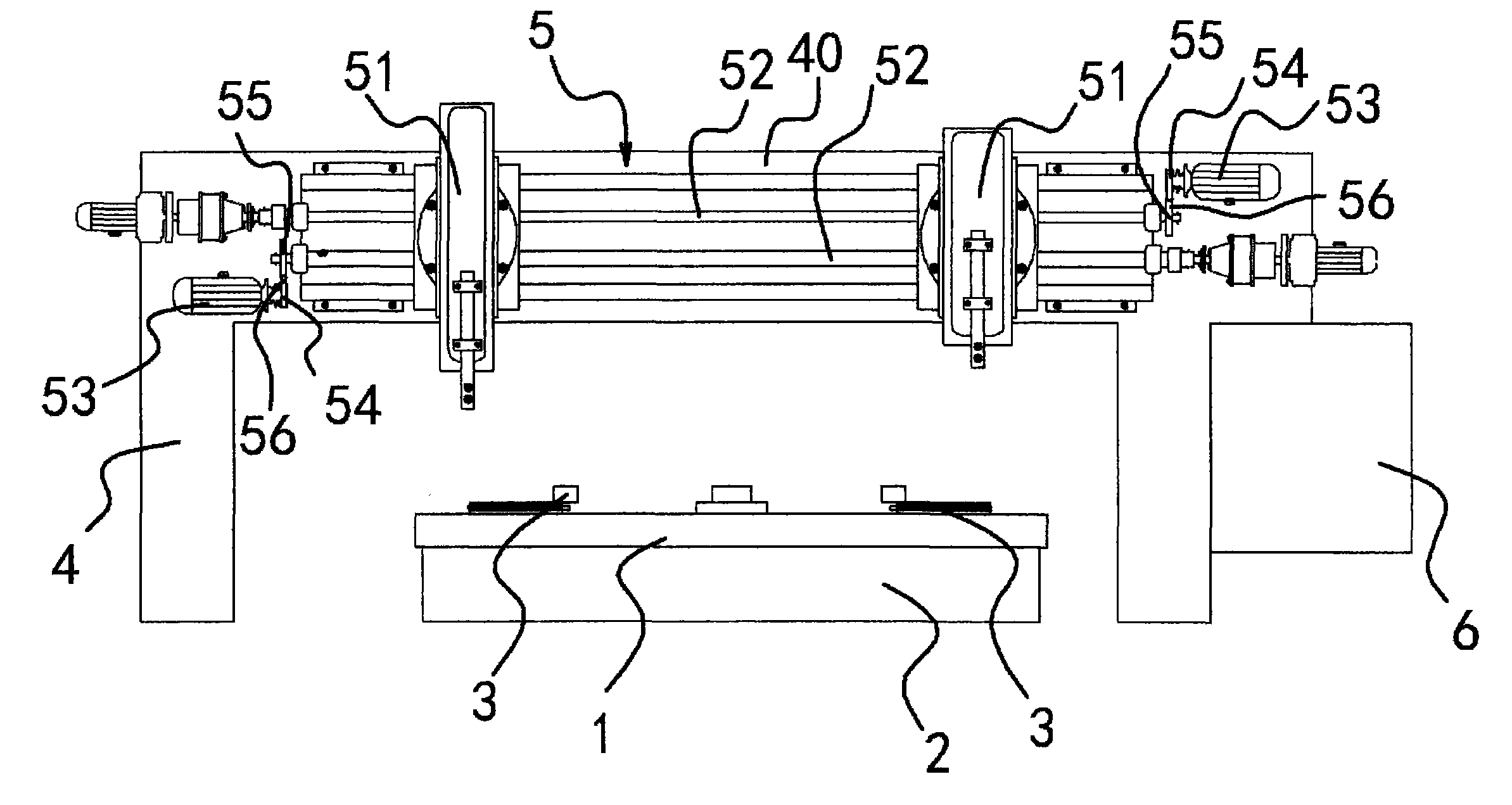

[0017] like figure 1 As shown, the automatic milling machine includes a turntable 1 arranged horizontally, and the turntable 1 is connected with a rotary power mechanism 2 capable of driving it to rotate. Four fixtures 3 for fixing workpieces are arranged on the turntable 1 . The clamps 3 are evenly distributed on the circumference with the turntable 1 as the center. The rotary power mechanism 2 includes an electric motor and a reduction box, the input end of the reduction box is connected with the electric motor, and the output end of the reduction box is connected with the turntable 1 .

[0018] The milling machine also includes a bracket 4 that is independent from the turntable 1 and located above the turntable 1 , and the bracket 4 includes a horizontal beam 40 . Support 4 is formed by pouring cement. At least one set of milling cutter assembly 5 is arranged on the crossbeam 40 , and a cutter capable of processing workpieces is installed on the milling cutter assembly 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com