Detecting device of discharging slag from ladle

A technology of vibration detection and sensing parts, which is applied in the field of vibration detection devices for ladle slag, can solve the problems of small vibration amplitude, impact of ladle turret, high rigidity of operating arm, etc., to avoid vibration interference and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manner of the present invention will be described in detail below with reference to the accompanying drawings and in combination with preferred embodiments of the present invention.

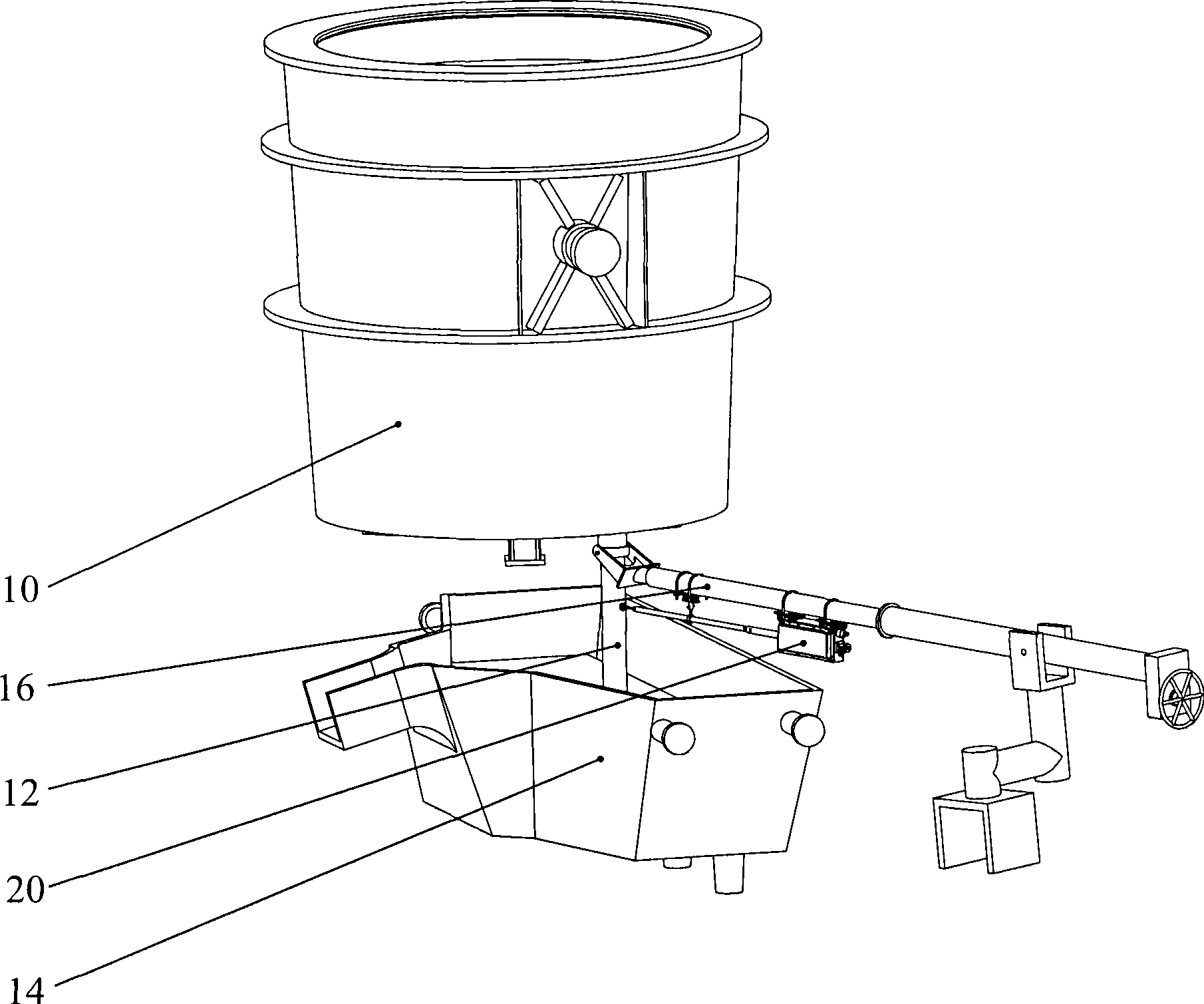

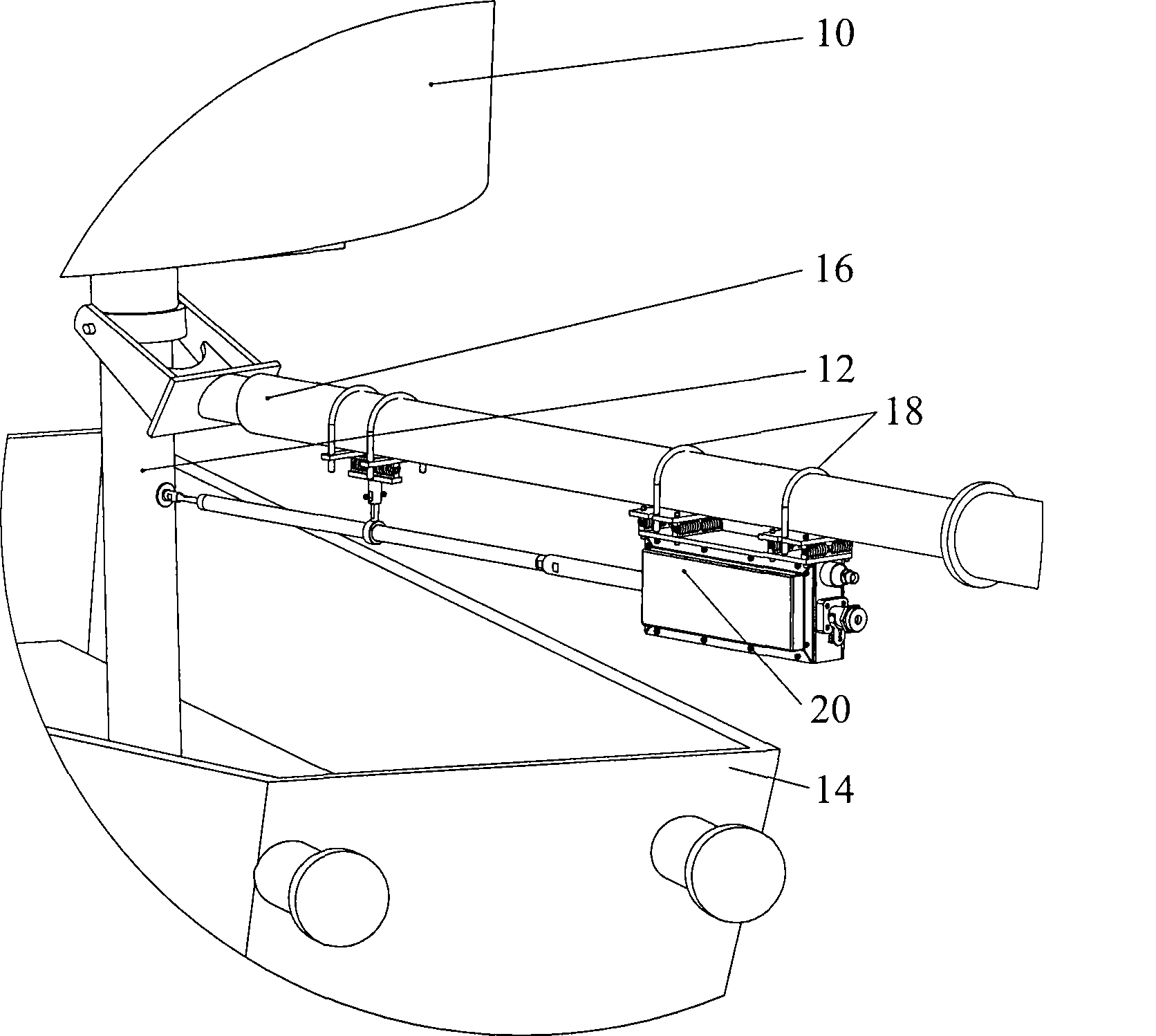

[0043] First refer to figure 1 and figure 2 , shows a ladle slag vibration detection device according to a preferred embodiment of the present invention. The vibration of the shroud protection sleeve 12 caused by molten steel. Such as figure 1 , 2 As shown, in this embodiment, the vibration detection device is installed on the mechanical arm 16, but in fact, in other embodiments, the vibration detection device according to the present invention can also be fixed on the ground.

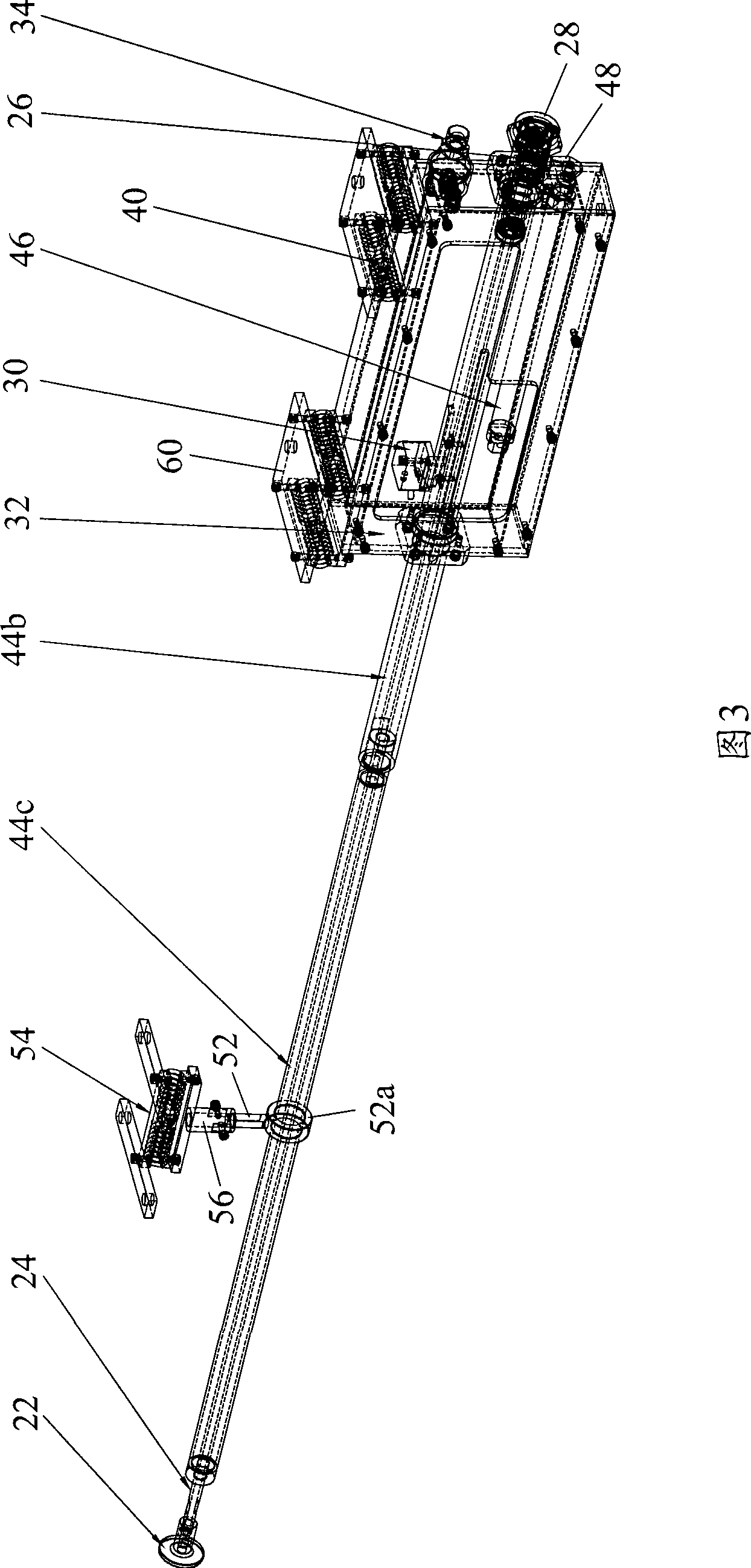

[0044] Such as figure 2 As shown in Fig. 3, the ladle slag vibration detection device of this preferred embodiment includes: a sensing mechanism, which selectively contacts the outer wall of the shroud protection sleeve 12 to sense the vibration of the shroud protection sleeve 12;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com