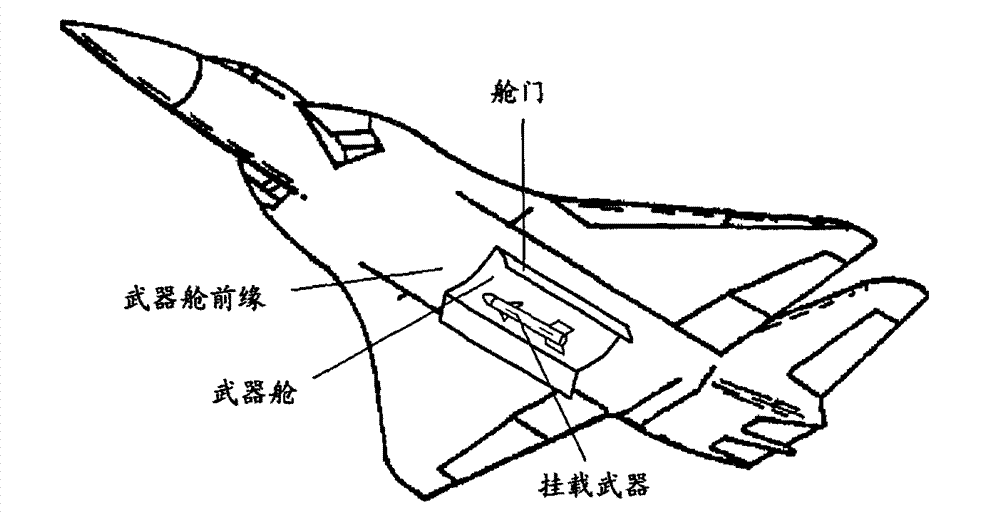

Noise reduction method for weapon cabin of supersonic aircraft on basis of turbulent flow on front-edge surface

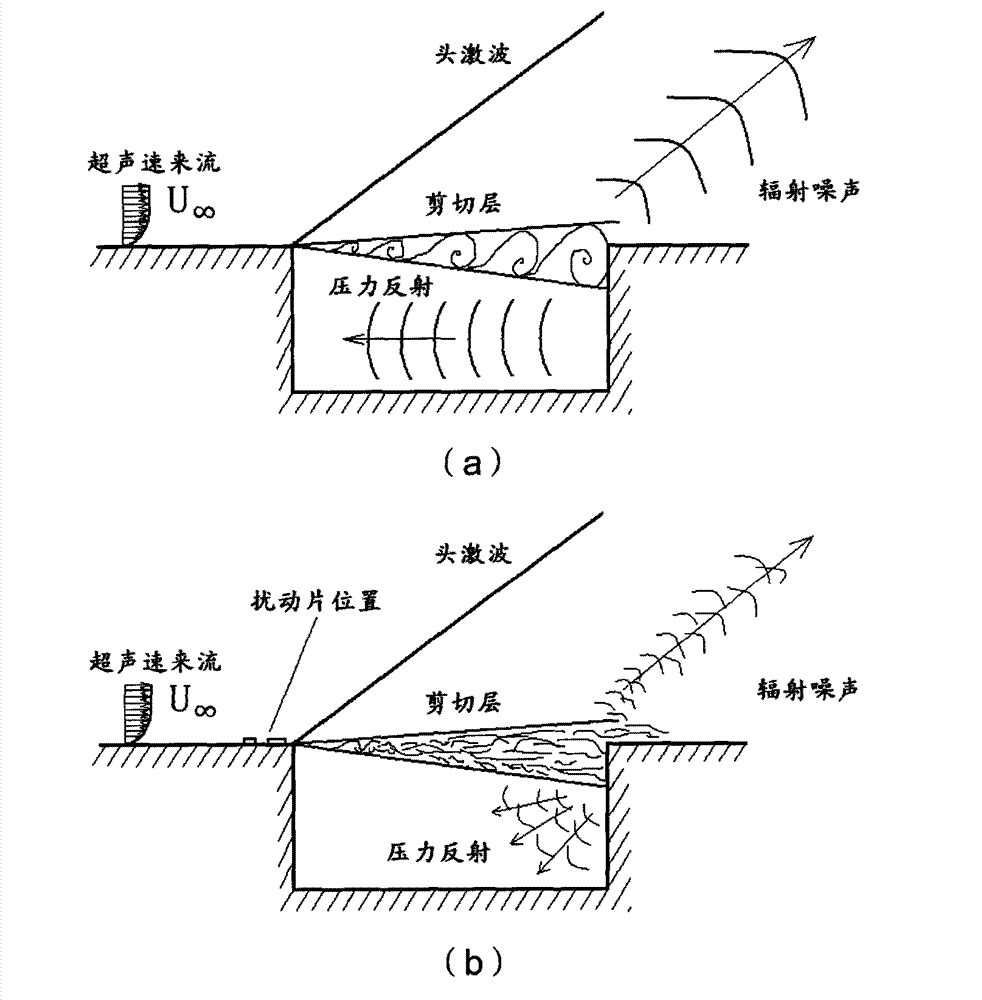

A weapon bay, supersonic technology, applied in the direction of affecting the air flow through the surface of the aircraft, aircraft parts, aircraft control, etc., can solve problems such as pressure self-sustained oscillation, and achieve the effect of avoiding disturbance, reliable function and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

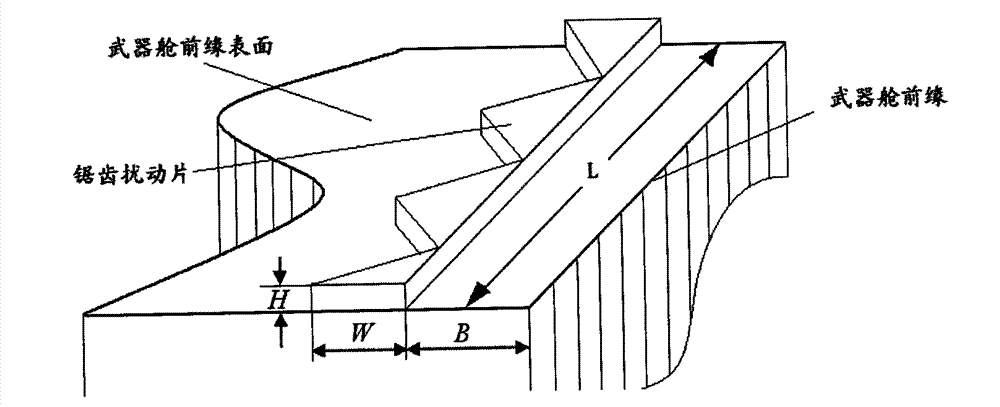

[0037] The general flight altitude of the aircraft is 0km~15km, and the flight Mach number is 0~3. Simplify the weapon compartment into a rectangular square cavity, for example: the depth of the cavity is 150mm, the length is 450mm, and the aspect ratio is 3; the flight Mach number is set to 1.5, and the sea level value is used as a reference. The density is 1.225kg / m 3 , the flow temperature is 288.16K, then the dynamic viscosity coefficient is 1.7894×10 -5kg / (m s), the thickness of the boundary layer on the surface of the front edge of the square cavity is 5mm, based on the thickness of the boundary layer on the front edge of the square cavity Re δ The number is 1.73×10 5 .

[0038] 1) if image 3 , the thickness H of the disturbance plate is selected as 25% of the local boundary layer thickness of 5mm, that is, H=1.25mm.

[0039] 2) if image 3 , W represents the width of the perturbation sheet. The linear stability analysis method obtains the most unstable disturban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com