Ball-dragging-type viscometer

A viscometer and drag-ball technology, applied in the field of drag-ball viscometers, can solve the problems of low measurement accuracy, unfavorable automatic measurement, etc., and achieve the effects of high measurement sensitivity and precision, widened measurement range and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further explained below in conjunction with the drawings.

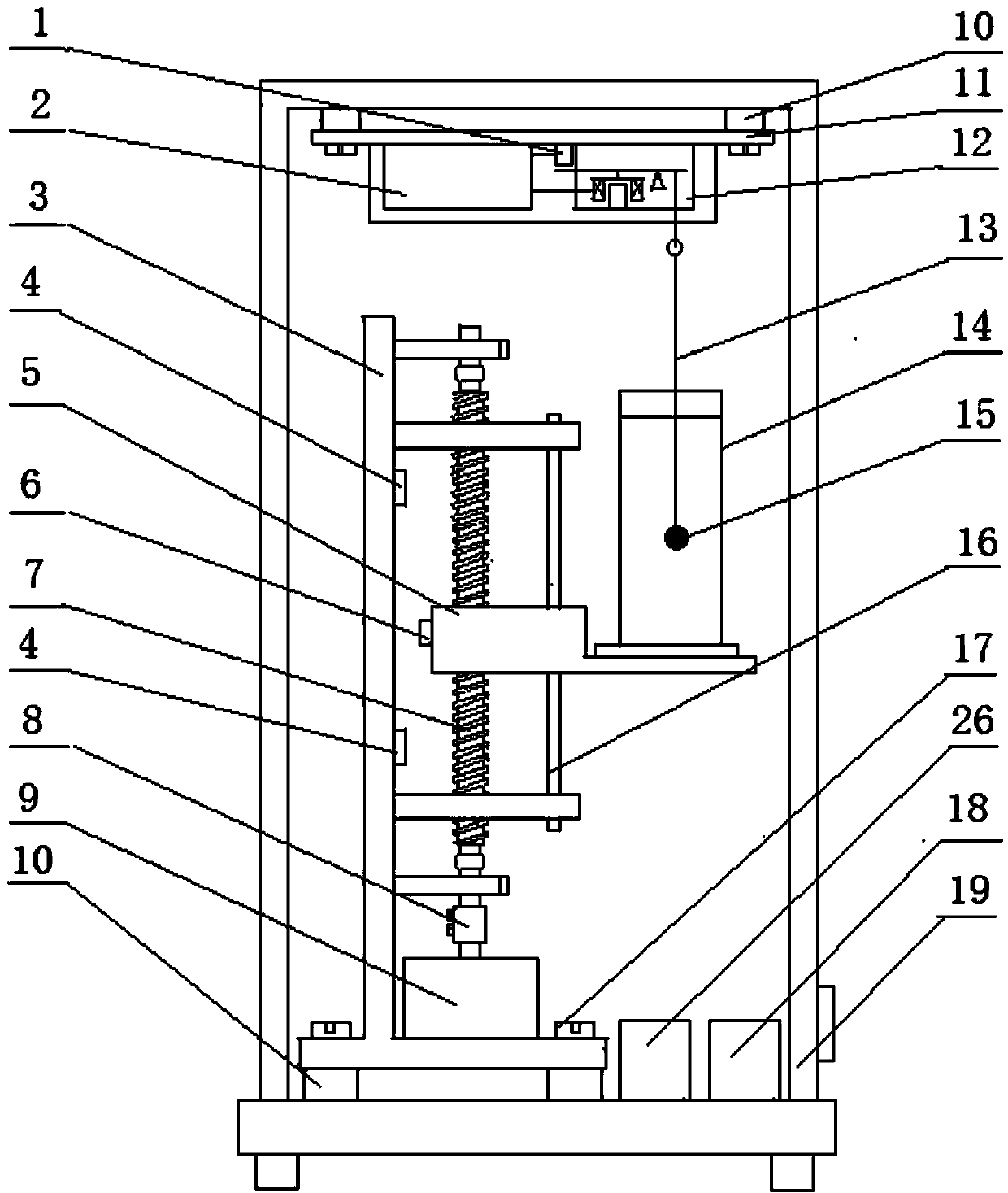

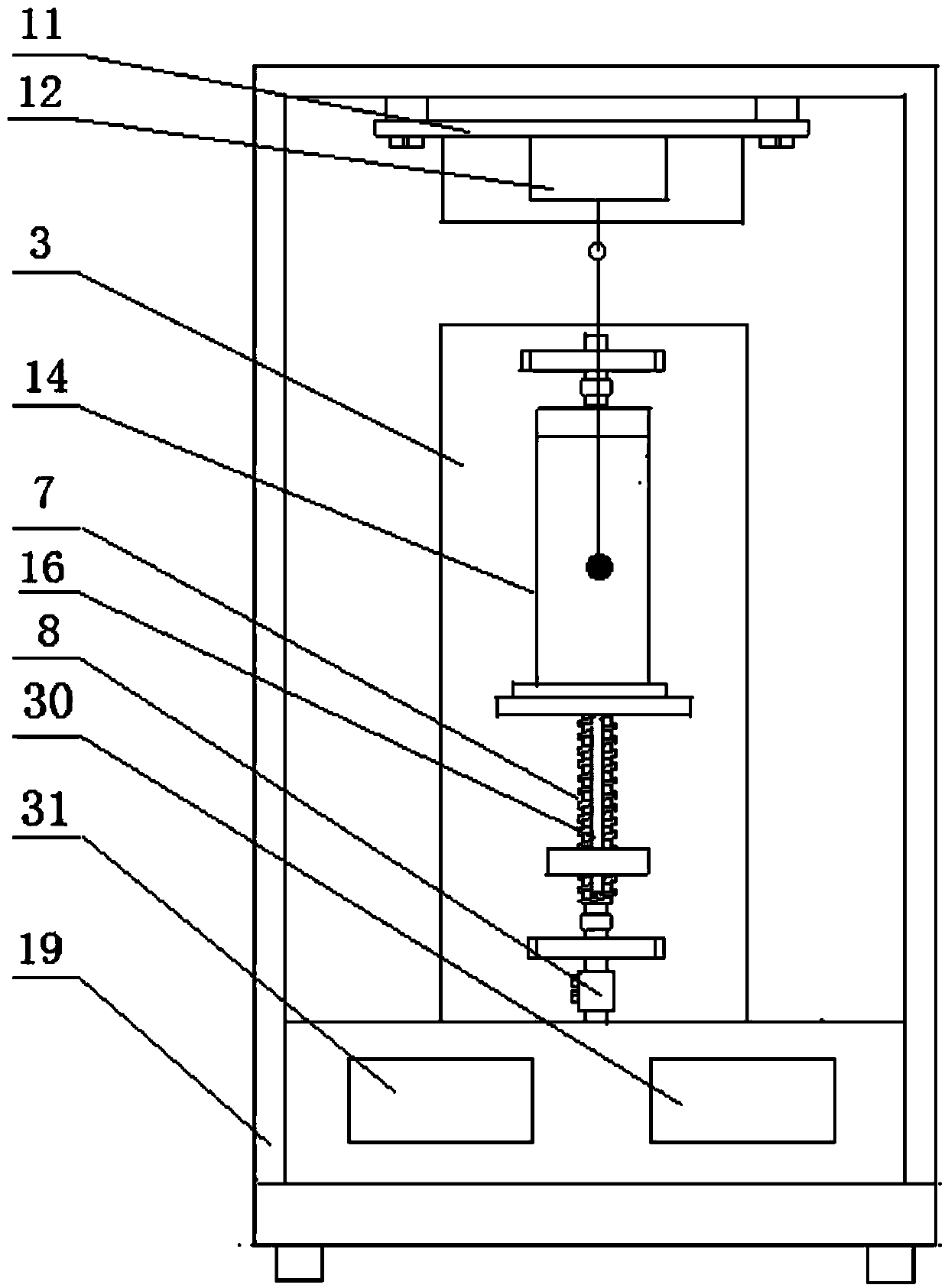

[0046] A drag-ball type viscometer includes a housing 19 in which a spiral transmission mechanism, a speed control system and a tension detection system are arranged, such as figure 1 , figure 2 As shown, the structure of the speed control system is: including a controller 25, a servo motor 27, a motor driver 26, and a rotary encoder 28. The servo motor 27 is connected to the controller 25 through the motor driver 26, and the rotary encoder 28 is connected to the Controller 25 is connected;

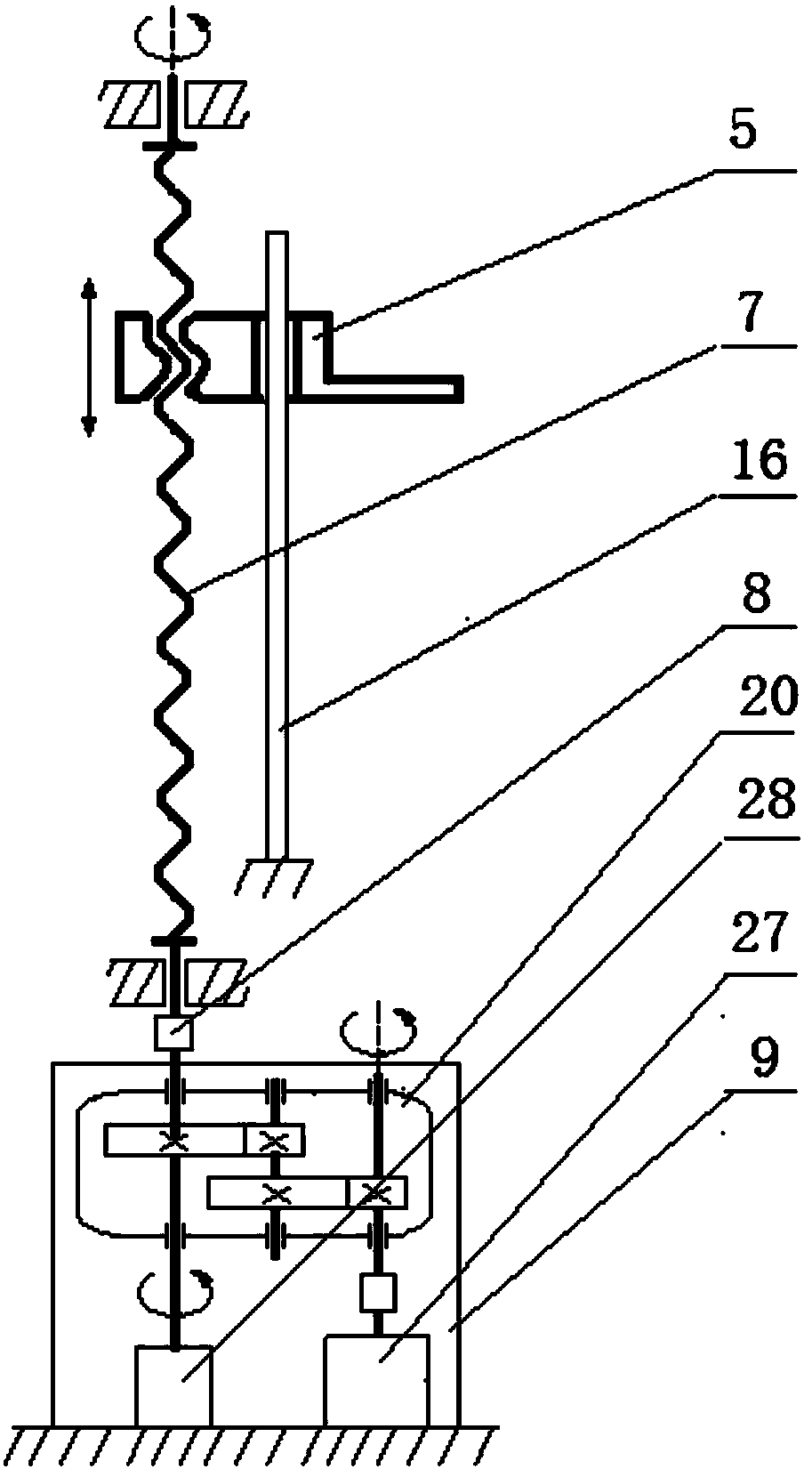

[0047] The structure of the screw transmission mechanism is: including the transmission assembly 9 (composed of the servo motor 27, the rotary encoder 28, and the transmission 20), the coupling 8, the screw 7, the nut block 5, the guide rod 16, and the Hall limit switch 4, such as image 3 As shown, the transmission assembly 9, the coupling 8, and the screw 7 are connected in sequence, the nut bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com