Method for grafting maleic anhydride onto polypropylene resin

A technology for grafting polypropylene and polypropylene resin, applied in the field of preparation of polypropylene resin grafts, can solve problems such as the inability to completely solve the problem of polypropylene degradation, and achieve high grafting conversion efficiency and high grafting rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

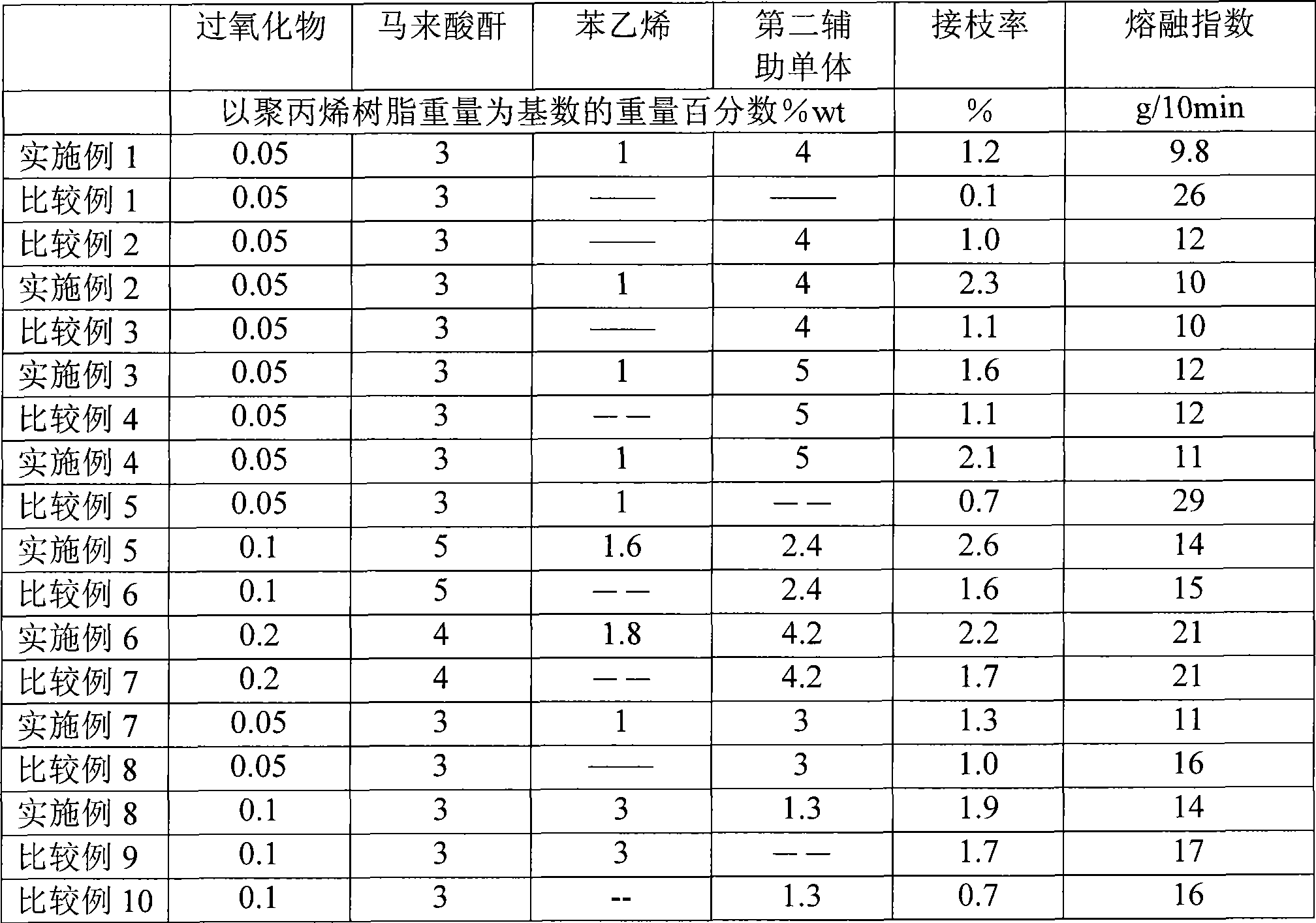

Embodiment 1

[0031] 0.02 gram of initiator dicumyl peroxide (produced by Beijing Duxin Fine Preparation Factory) was added by 0.4 gram of styrene (produced by Tianjin Guangfu Fine Chemical Research Institute) and 1.6 gram of trimethylolpropane triacrylate (produced by Beijing Dongfang Chemical Industry Co., Ltd. Factory) dissolved in the auxiliary monomer mixture mixed. Put 40 grams of polypropylene powder (Bluestar Group Tianjin Petrochemical 3# special material, powder without antioxidant, melt index 3.0-5.9g / 10min) and 1.2 grams of ground maleic anhydride powder in a plastic beaker Perform solid-phase dry mixing with a stirring paddle, and uniformly add the above-dissolved auxiliary monomer mixed solution containing the peroxide initiator during the mixing process. Finally, the mixed reactant was added into a Brabender PLE 651 type mixer, and at a temperature of 180° C., mixed at a speed of 30 rpm for 6 minutes, and then added with a weight ratio of 1:1 antioxidant 1010 ( Tetraerythrit...

Embodiment 2

[0037] The second auxiliary monomer trimethylolpropane triacrylate used in Example 1 was replaced by trimellitic acid tripropylene, and the remaining components and experimental conditions were the same as in Example 1. The relevant test results of the prepared samples are shown in Table 1.

Embodiment 3

[0041] The amount of the second auxiliary monomer trimethylolpropane triacrylate used in Example 1 was changed to 2.0 grams, and the remaining components and experimental conditions were the same as in Example 1. The relevant test results of the prepared samples are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com