Additive for papermaking

A technology of additives and polymers, applied in the direction of papermaking, textiles and papermaking, non-fiber pulp addition, etc., can solve unsatisfactory problems, achieve excellent drainage, excellent filler retention, and excellent paper strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

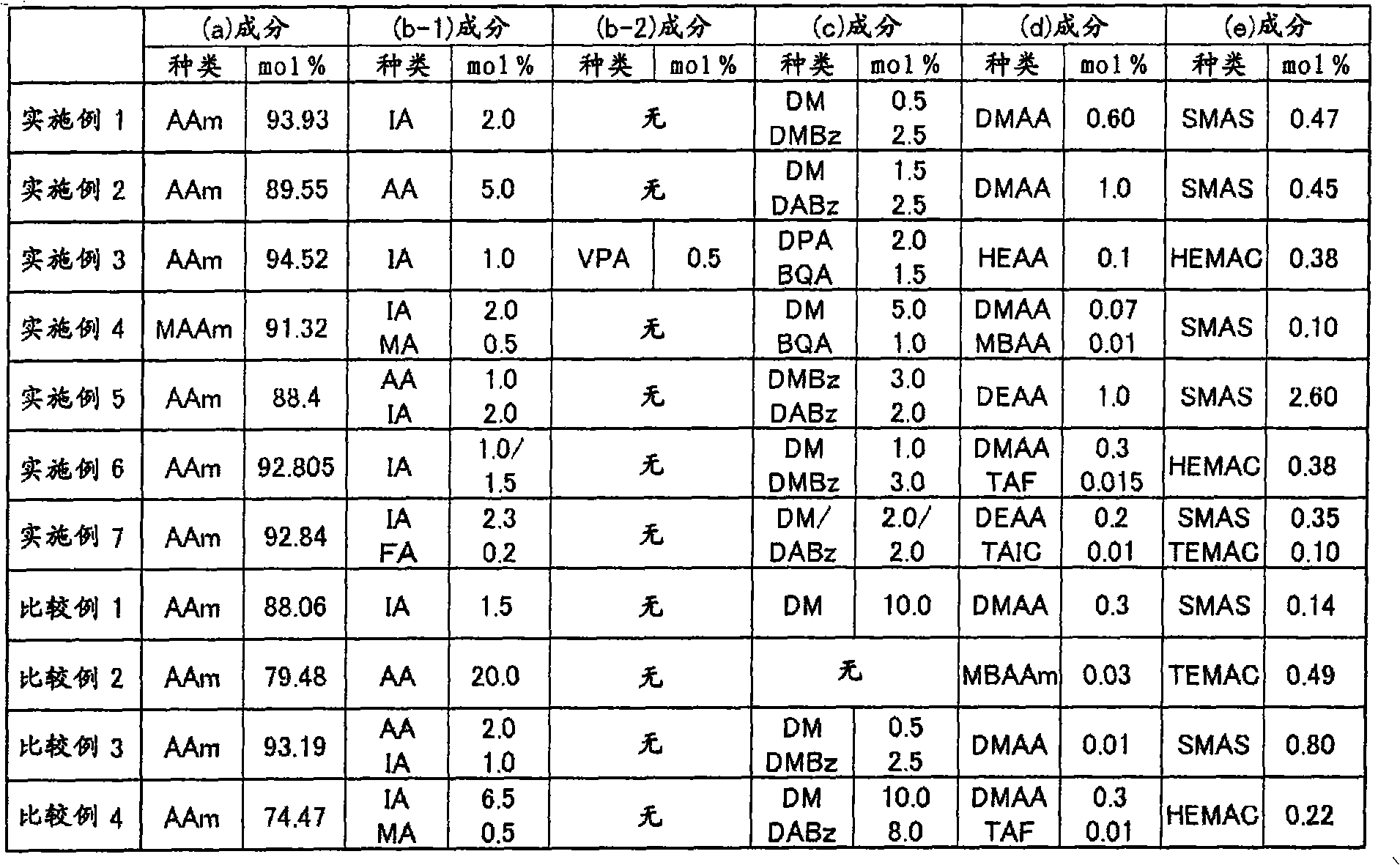

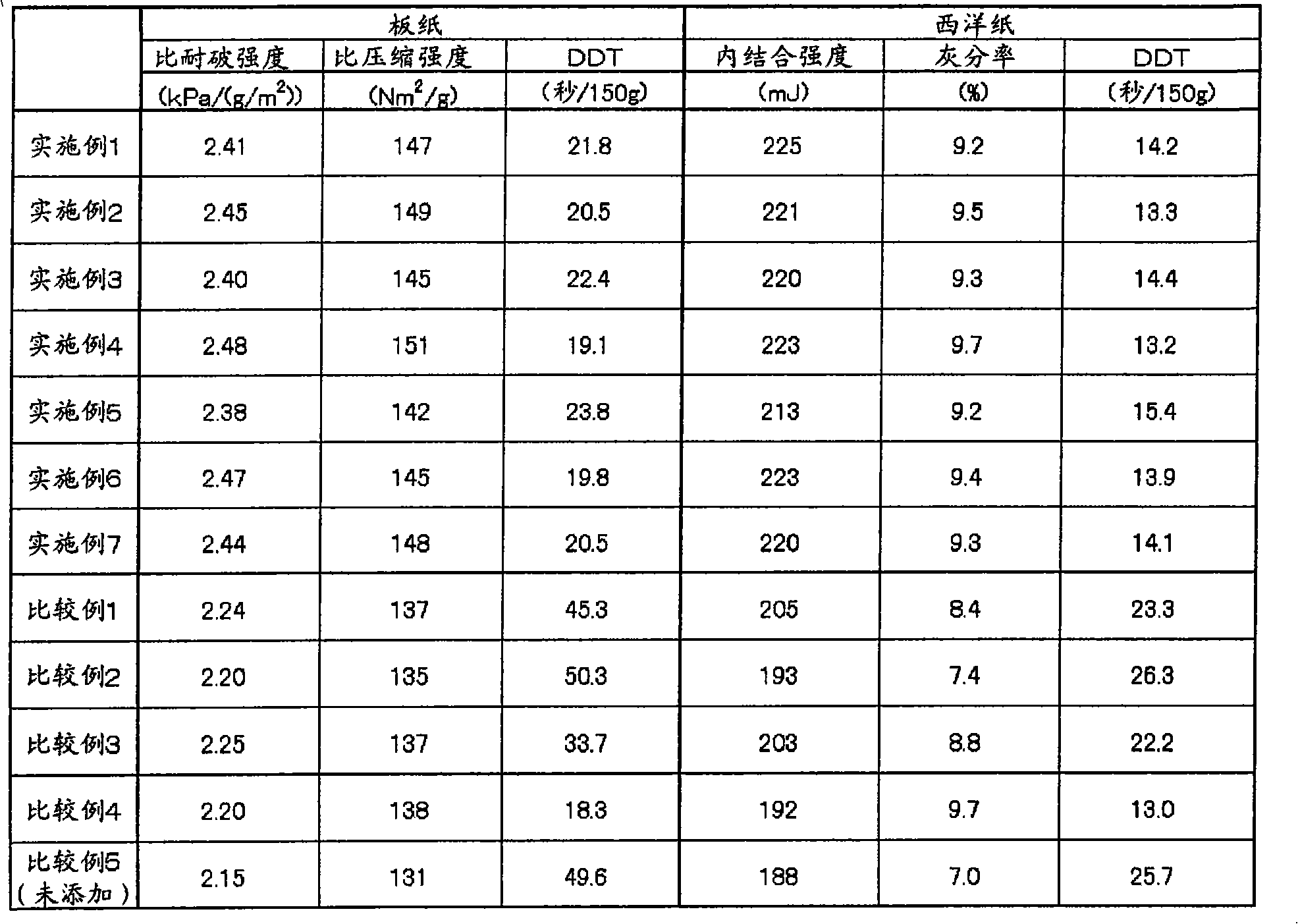

[0114] Add 483 parts of water, 267.06 parts of 50% acrylamide aqueous solution, 1.57 parts of dimethylaminoethyl methacrylate, 76% methyl 18.67 parts of dimethylaminoethyl acrylate aqueous solution of benzyl ammonium chloride, 5.2 parts of itaconic acid, 1.19 parts of N,N-dimethylacrylamide, 1.49 parts of sodium methallylsulfonate, and then add 30% 1.8 parts of sulfuric acid aqueous solution was adjusted to pH 3.0, and the temperature was raised to 60° C. under a nitrogen atmosphere. Next, 4.56 parts of a 5% ammonium persulfate aqueous solution was added as a polymerization initiator to start polymerization, and the temperature was raised to 90° C. under a nitrogen atmosphere, and the temperature was maintained. 9.12 parts of a 5% ammonium persulfate aqueous solution was added 1 hour after the start of the polymerization, and 2 hours after the start of the polymerization, it was cooled to room temperature to stop the polymerization. The solid content of the obtained papermaki...

Embodiment 2、3

[0116] As shown in Table 1, except having changed the kind and quantity of the components (a)-(e) in Example 1, it carried out similarly to Example 1, and obtained the additive for papermaking. Table 2 shows properties of the obtained papermaking additives.

Embodiment 4

[0118]Add 835.94 parts of water, 77.72 parts of methacrylamide, 7.86 parts of dimethylaminoethyl methacrylate, 64.7% 2-hydroxy -N,N,N,N',N'-pentamethyl-N'-[3-{(1-oxo-2-propenyl)amino}propyl]-1,3-propanediammonium dichloride 5.32 parts of aqueous solution, 2.6 parts of itaconic acid, 0.49 parts of maleic anhydride, 0.07 parts of N,N-dimethylacrylamide, 0.02 parts of methylenebisacrylamide, 0.16 parts of sodium methallylsulfonate, and then add 8.0 parts of 30% sulfuric acid aqueous solution was adjusted to pH 3.0, and it heated up to 60 degreeC in nitrogen atmosphere. Next, 2.28 parts of a 5% ammonium persulfate aqueous solution was added as a polymerization initiator to start polymerization, and the temperature was raised to 90° C. under a nitrogen atmosphere, and the temperature was maintained. 4.56 parts of a 5% ammonium persulfate aqueous solution was added 1 hour after the start of the polymerization, and 2 hours after the start of the polymerization, it was cooled to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com