Stepped aerogenesis dry powder extinguishing device

A technology of dry powder fire extinguishing and dry powder fire extinguishing agent, which is applied in fire rescue and other directions, can solve the problems of fast pressure decay, short duration, frictional overheating, etc., and achieve the effects of slowing down the gas production process, long gas production time, and preventing bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

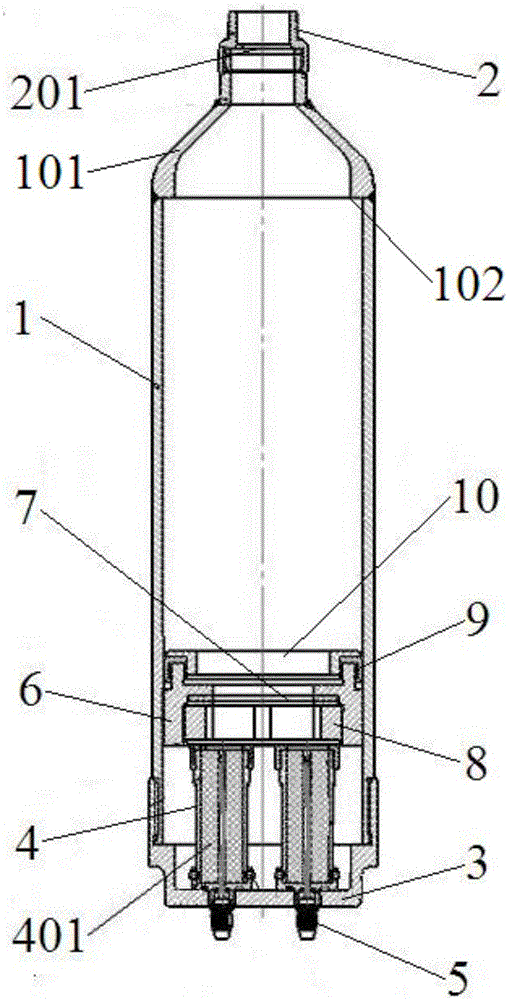

[0027] refer to figure 1 According to an embodiment of the present invention, a step-type gas-producing dry powder fire extinguishing device is proposed, including a tank body 1, a piston assembly and a step-type gas generating device, the tank body 1 stores a dry powder fire extinguishing agent, and the tank body 1 has The first end and the second end, the first end of the tank body 1 is provided with a pipeline connector 2 for connecting the collecting pipeline, and a moisture-proof membrane 201 is arranged inside the pipeline connector 2, and the tank body 1 The second end of the second end is provided with a lower end cover 3; the piston assembly is slidably arranged on the inner side of the tank body 1, and the middle part of the piston assembly is provided with a pressure diaphragm 7; the stepped gas generating device is arranged at the lower end In the space between the cover 3 and the piston assembly.

[0028] In the above embodiments, the dry powder fire extinguishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com