Electro-hydraulic switch torque-changing oil-dispensing type rotating cylinder barrel type quantitative plunger piston hydraulic motor

A technology of hydraulic motors and rotary cylinders, applied in the field of hydraulic motors, can solve problems such as hydraulic motor leakage and leakage of hydraulic motor working pressure, and achieve the effect of increasing driving pressure and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

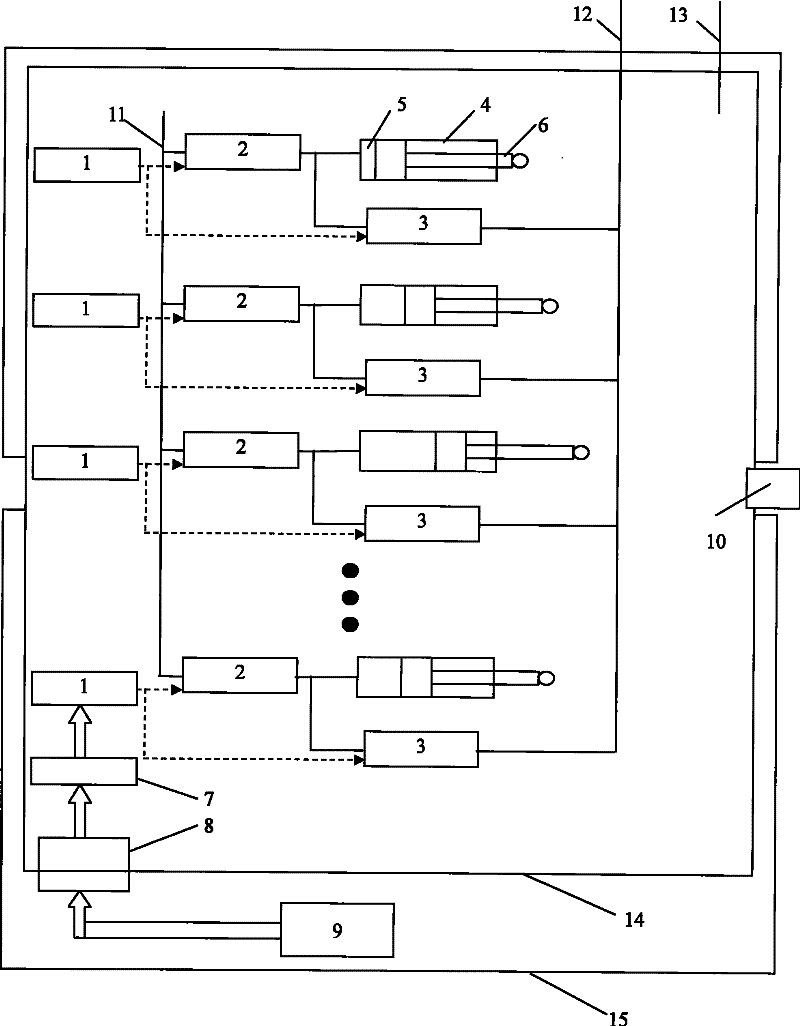

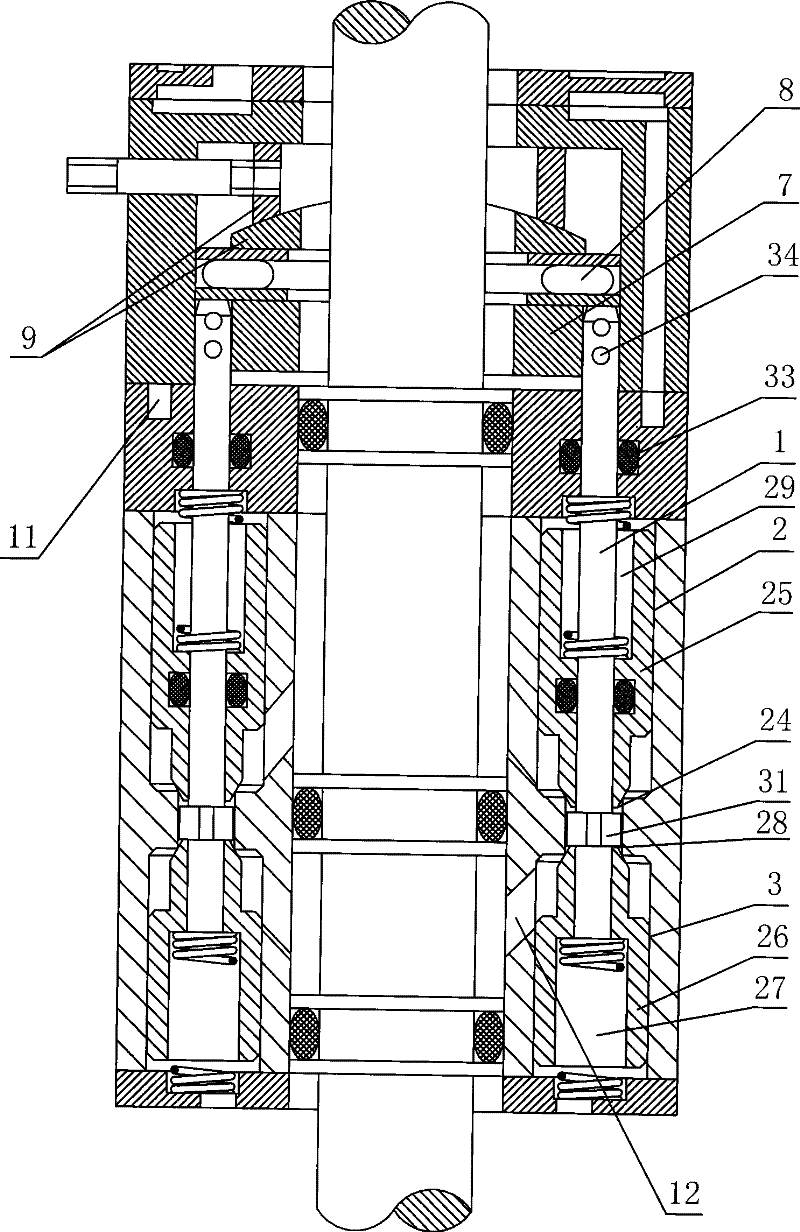

[0032] In conjunction with the accompanying drawings, the present invention will be described in detail below through specific embodiments.

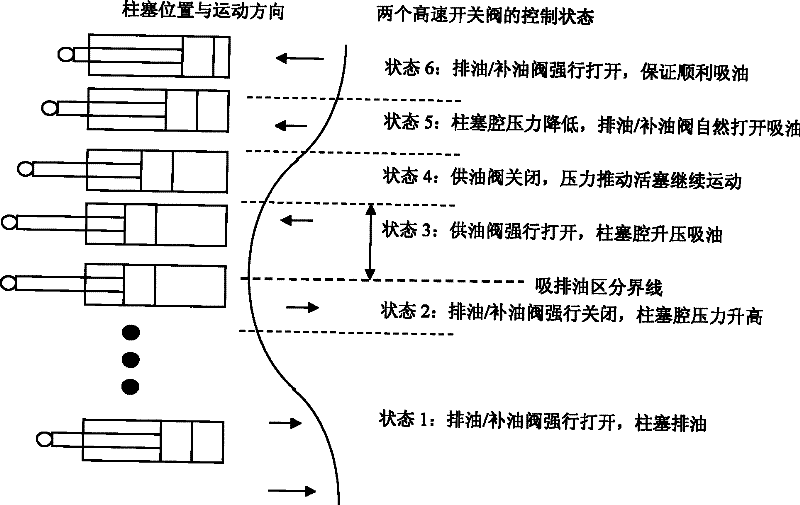

[0033] A rotary cylinder type quantitative plunger hydraulic motor with mechanical-hydraulic switch variable torque oil distribution type in this specific embodiment includes a motor housing, a plunger and a drive plate, and also includes an oil distribution valve group and a mechanical-hydraulic variable torque drive mechanism , the oil distribution valve group is composed of integrated valves with the same number as the number of plungers; each integrated valve is composed of a high-speed switch high-pressure oil supply valve and a corresponding high-speed switch oil discharge / supplement valve, and the high-speed switch high-pressure oil valve in the integrated valve The oil supply valve and the valve port of the high-speed switch oil discharge / supplement valve are arranged face to face, and the end faces of the two valve cores leave sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com