A kind of preparation method of cnt/iir composite material and jet atomization gun for preparation thereof

A composite material and spray atomization technology, applied in the field of spray atomization guns, can solve the problems of re-agglomeration of fillers, large water consumption, long time consumption, etc., and achieve the effects of low production cost, low rolling resistance, and environmentally friendly use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

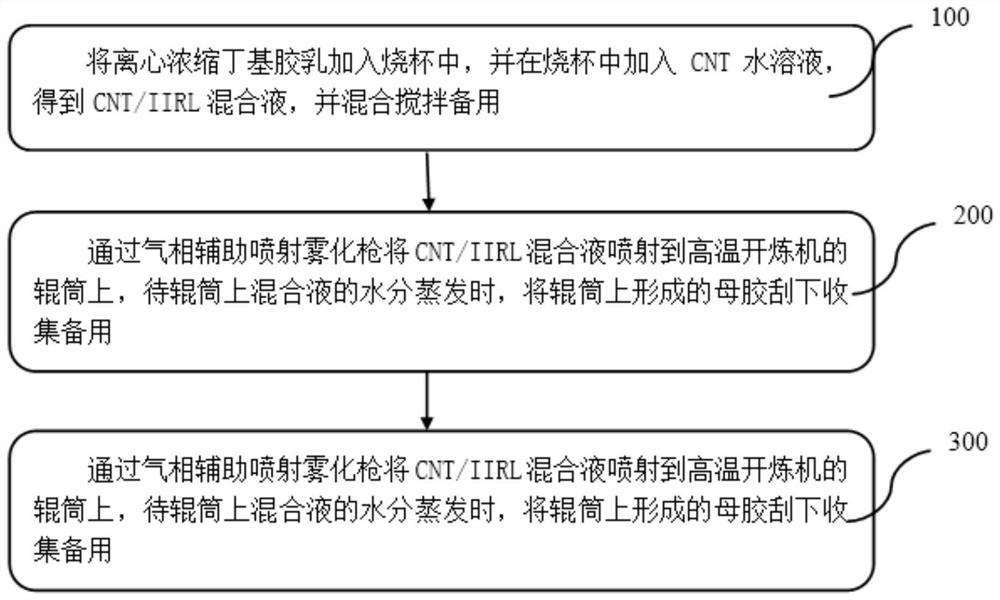

[0041] Such as figure 1 As shown, the invention provides a kind of CNT / IIR composite material preparation method, it is characterized in that: comprise the steps:

[0042] S100, adding centrifugally concentrated butyl latex into a beaker, and adding a CNT aqueous solution into the beaker to obtain a CNT / IIRL mixed solution, and mixing and stirring for later use.

[0043] S200. Spray the CNT / IIRL mixture onto the rollers of the high-temperature mill through a gas-assisted spray gun. When the water in the mixture evaporates on the rollers, scrape off the masterbatch formed on the rollers and collect them for later use.

[0044] S300, add 111phr masterbatch, zinc oxide ZnO, stearic acid SAD, sulfur, super-accelerator TMTD, DM accelerator, RD anti-aging agent, anti-aging agent 4020 in the open mill in order to carry out mixing and carry out the mastication and mixing of the masterbatch Banbury mixing to complete the preparation of GO / IIR composite materials.

[0045]In S100, sel...

Embodiment 2

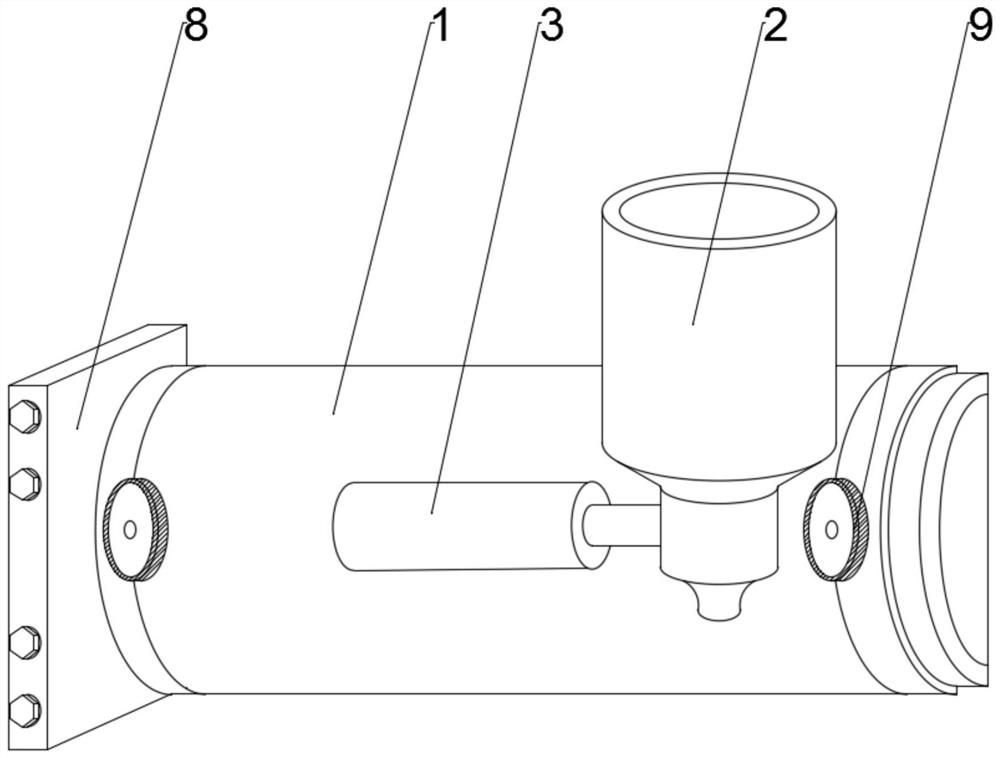

[0052] Such as Figure 2 to Figure 5 As shown, the present invention also provides a kind of spray atomization gun that is used for the preparation of CNT / IIR composite material in embodiment 1, comprises assembly frame 1, and the batching bottle 2 that is arranged on the assembly frame 1, is positioned at batching bottle An air pump 3 is installed on the assembly frame 1 on one side, and the prepared CNT / IIRL mixture is injected into the batching bottle 2, and the jet air pressure is provided by the air pump 3 and the pressure change in the batching bottle 2 is controlled to achieve uniformity. Jetting under pressure.

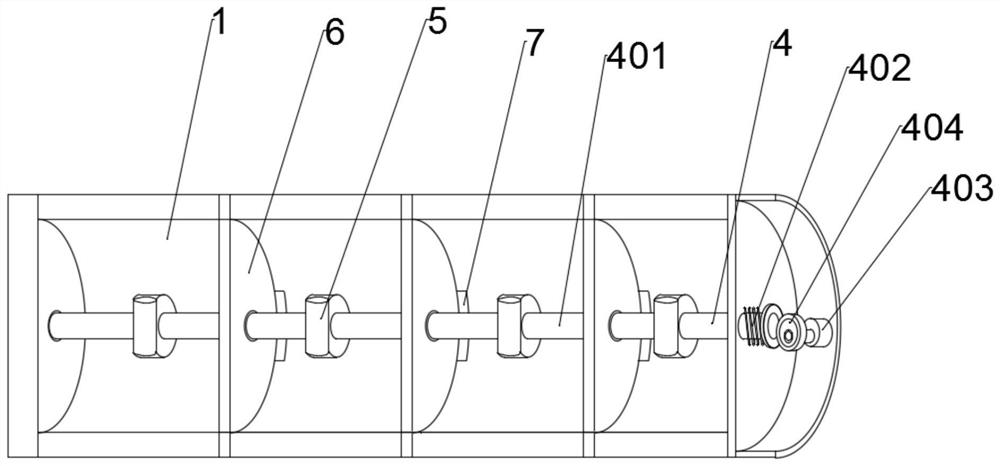

[0053] The inner side of the assembly frame 1 of the present invention is provided with a micro-movement assembly 4, and several atomizing nozzles 5 are arranged on the micro-motion assembly 4, and the left and right lateral vibrations of the atomizing nozzles are driven by the micro-motion assembly 4, thereby ensuring the stability of the atomizing nozzles 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com