White carbon black dispersant and preparation method thereof

A technology of dispersant and white carbon black, applied in the field of white carbon black dispersant and its preparation, can solve problems such as potential toxicity of underwater organisms, and achieve the effects of improving wet skid resistance, environmental protection of preparation process and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

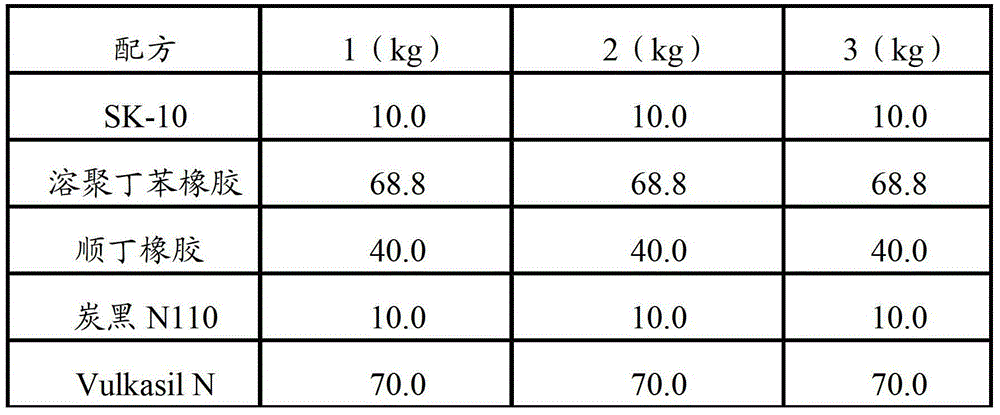

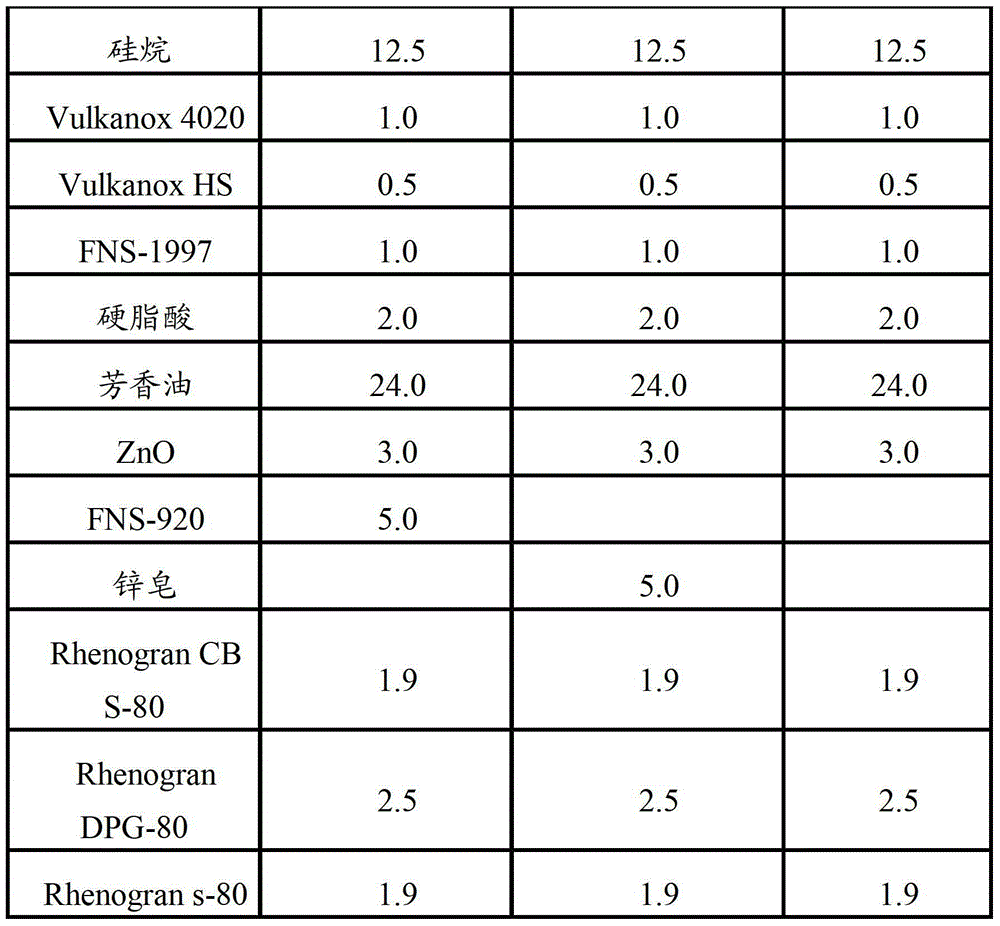

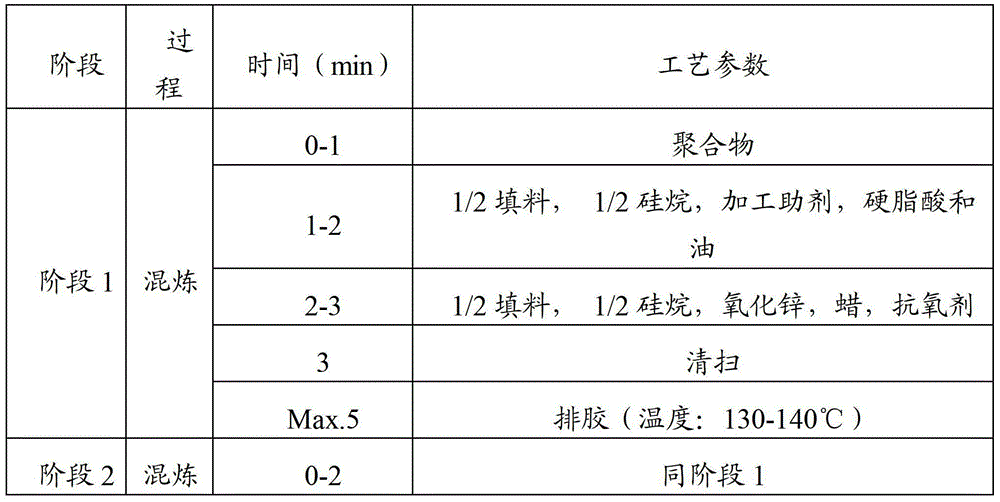

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 preparation of white carbon black dispersant

[0026] Add 300kg of 12-hydroxystearic acid into the reactor, stir and heat to 100-110°C, then add 25kg of 58# wax and 140kg of pentaerythritol tetrastearate. After the material is completely melted, continue to stir for 15 minutes, add 30 kg of calcium carbonate and 5 kg of 2,6-di-tert-butyl-4-methylphenol and continue to stir for 15 minutes. Cool to room temperature and discharge to obtain a white carbon black dispersant. The whole process produces no waste residue and waste water.

Embodiment 2

[0027] Embodiment 2 preparation of white carbon black dispersant

[0028] Add 260kg of mixed C8-C22 fatty acids into the reactor, wherein the mixed C8-C2 fatty acids include 130kg of palm oil fatty acid and 130kg of tallow fatty acid, stir and heat to 100-110°C, then add 125kg of 58# wax and pentaerythritol tetrahard Fatty acid ester 50kg. After the material is completely melted, continue stirring for 15 minutes, add 40 kg of calcium carbonate and 25 kg of 2,6-di-tert-butyl-4-methylphenol and continue stirring for 15 minutes. Cool to room temperature and discharge to obtain a white carbon black dispersant. The whole process produces no waste residue and waste water.

Embodiment 3

[0029] Embodiment 3 preparation of white carbon black dispersant

[0030] Add 250kg of mixed C8-C22 fatty acids into the reactor, wherein the mixed C8-C22 fatty acids include 150kg of palm oil fatty acids and 100kg of soybean oil fatty acids, stir and heat to 100-110°C, then add 75kg of mixed protective wax and 150kg of palm wax, wherein , The mixed protective wax includes 50kg58# wax and 25kg polyethylene wax. After the materials are completely melted and continue to stir for 15 minutes, add 40kg of mixed inorganic fillers of calcium carbonate and calcium sulfate and 5kg of 2,6-di-tert-butyl-4-methylphenol and continue to stir for 15 minutes, wherein the mixed inorganic fillers include 35kg Calcium carbonate and 5kg calcium sulfate. Cool to room temperature and discharge to obtain a white carbon black dispersant. The whole process produces no waste residue and waste water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com