Colloidal bismuth pectin capsule and preparation process thereof

A technology of colloidal bismuth pectin and preparation process is applied in the directions of capsule delivery, medical preparations without active ingredients, medical preparations containing active ingredients, etc. To achieve the effect of simple preparation process, strong adsorption, easy to industrialize large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

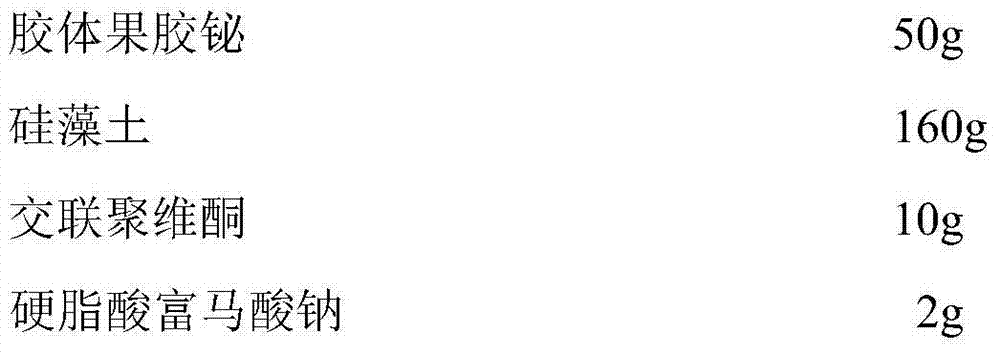

Embodiment 1

[0025]

[0026] Preparation Process:

[0027] (1) adding colloidal bismuth pectin and diatomaceous earth to pulverize in a ball mill to obtain a drug-containing adsorbate, and controlling the average particle diameter of the drug-containing adsorbate to be less than 30 microns;

[0028] (2) Mix the drug-containing adsorbate obtained in step (1) with crospovidone and sodium stearate fumarate evenly, and fill the capsule shell.

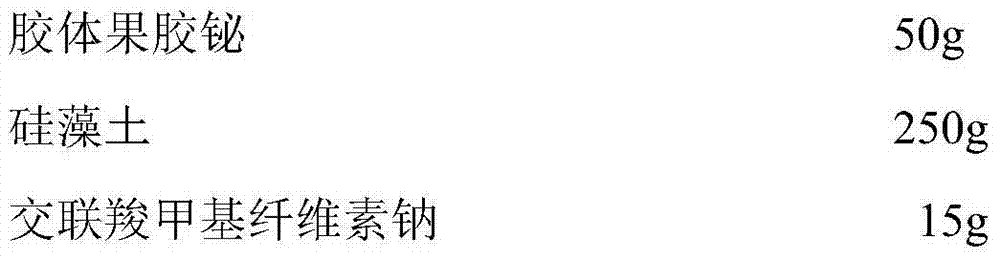

Embodiment 2

[0030]

[0031]

[0032] Preparation Process:

[0033] (1) adding colloidal bismuth pectin and diatomaceous earth to pulverize in a ball mill to obtain a drug-containing adsorbate, and controlling the average particle diameter of the drug-containing adsorbate to be less than 30 microns;

[0034] (2) Mix the drug-containing adsorbate obtained in step (1) with croscarmellose sodium and hydrogenated vegetable oil evenly, and fill the capsule shell.

Embodiment 3

[0036]

[0037] Preparation Process:

[0038] (1) adding colloidal bismuth pectin and diatomaceous earth to pulverize in a ball mill to obtain a drug-containing adsorbate, and controlling the average particle diameter of the drug-containing adsorbate to be less than 30 microns;

[0039] (2) Mix the drug-containing adsorbate obtained in step (1) with sodium carboxymethyl starch and magnesium stearate evenly, and fill the capsule shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com