GR-SiO2/IIR material preparation method and glue spraying device

A gr-sio2, spraying technology, applied in the field of rubber mixing, can solve the problems of poor rubber compatibility, decreased wear resistance, weak interaction, etc., to achieve easy mass production and popularization, low rolling resistance , low energy consumption and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as Figure 4 As shown, the present invention provides a GR-SiO 2 / IIR composite material preparation method, comprises the steps:

[0039] S100, mixing sodium silicate, deionized water, absolute ethanol and surfactant according to a certain mass ratio, and stirring in a water bath at 70-75°C to form a modified sodium silicate aqueous solution;

[0040] S200, adding an appropriate amount of lauric acid and 2mol / L hydrochloric acid to the modified sodium silicate aqueous solution, and ultrasonicating for half an hour in an ice-water bath to obtain a silica precipitation solution;

[0041] S300, filter and rinse the silica precipitation solution to obtain a modified silica solid-liquid mixture, place the modified silica solid-liquid mixture in a beaker, add an appropriate amount of deionized water, and adjust the pH value to neutral, Stir at high speed for 5-10 minutes;

[0042] S400, add an appropriate amount of deionized water to 30 parts by mass, and add 3 parts b...

Embodiment 2

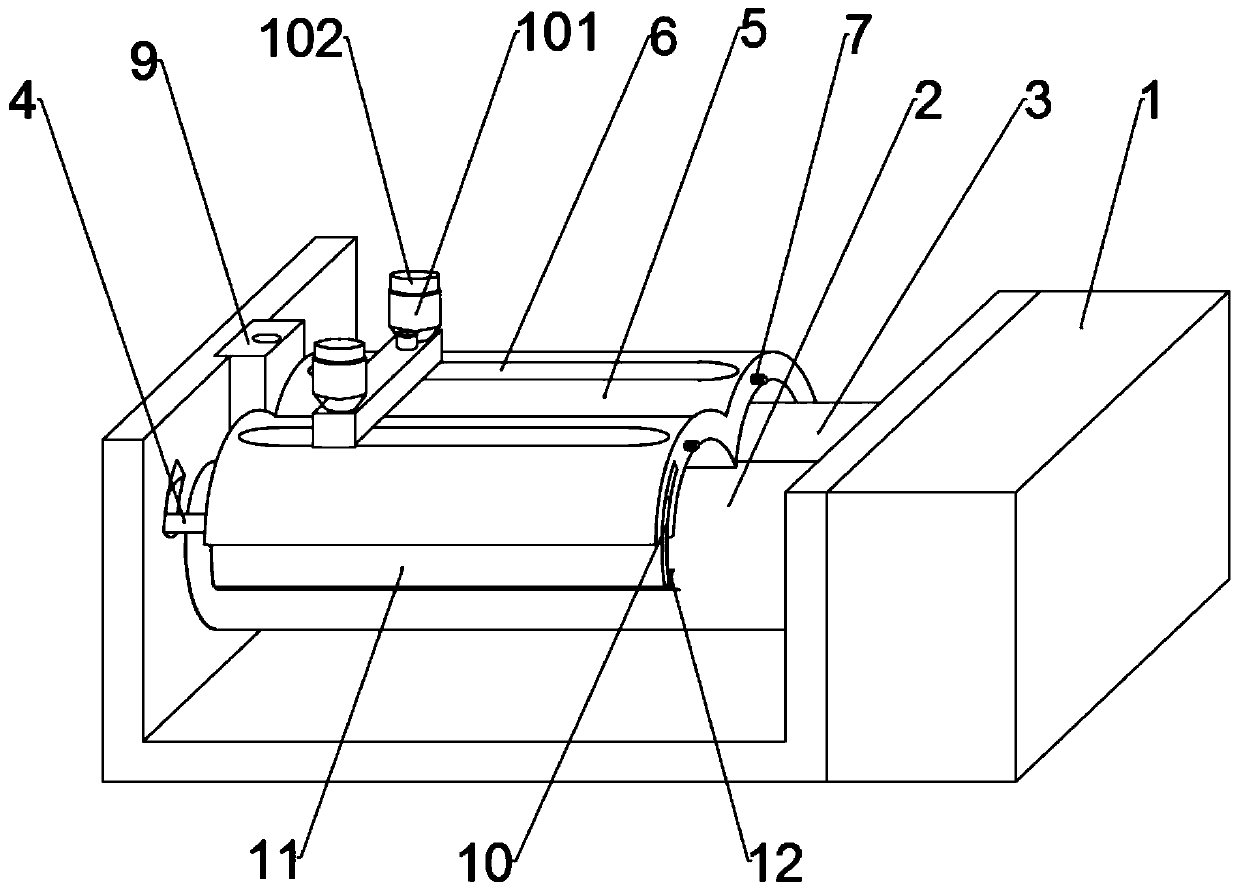

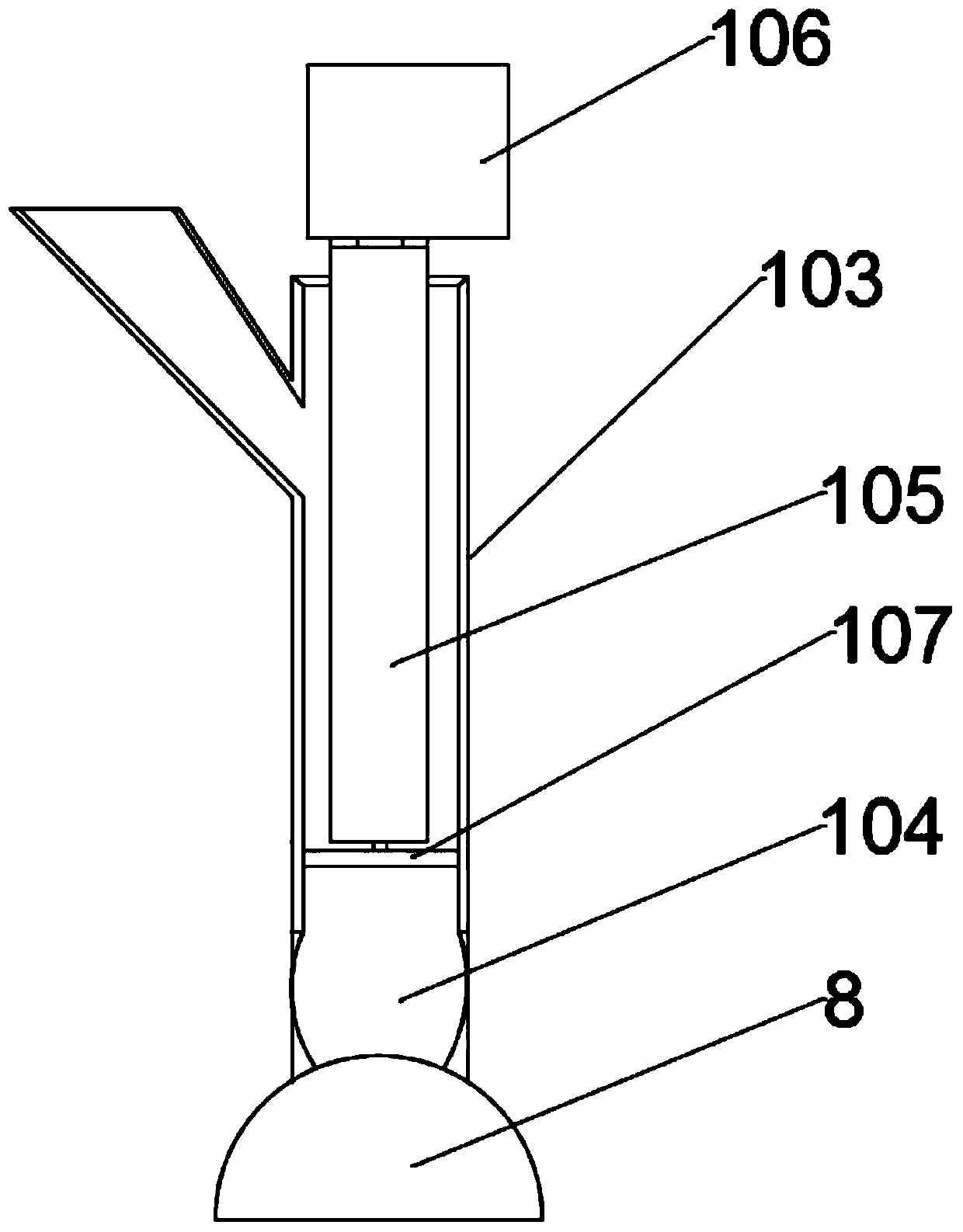

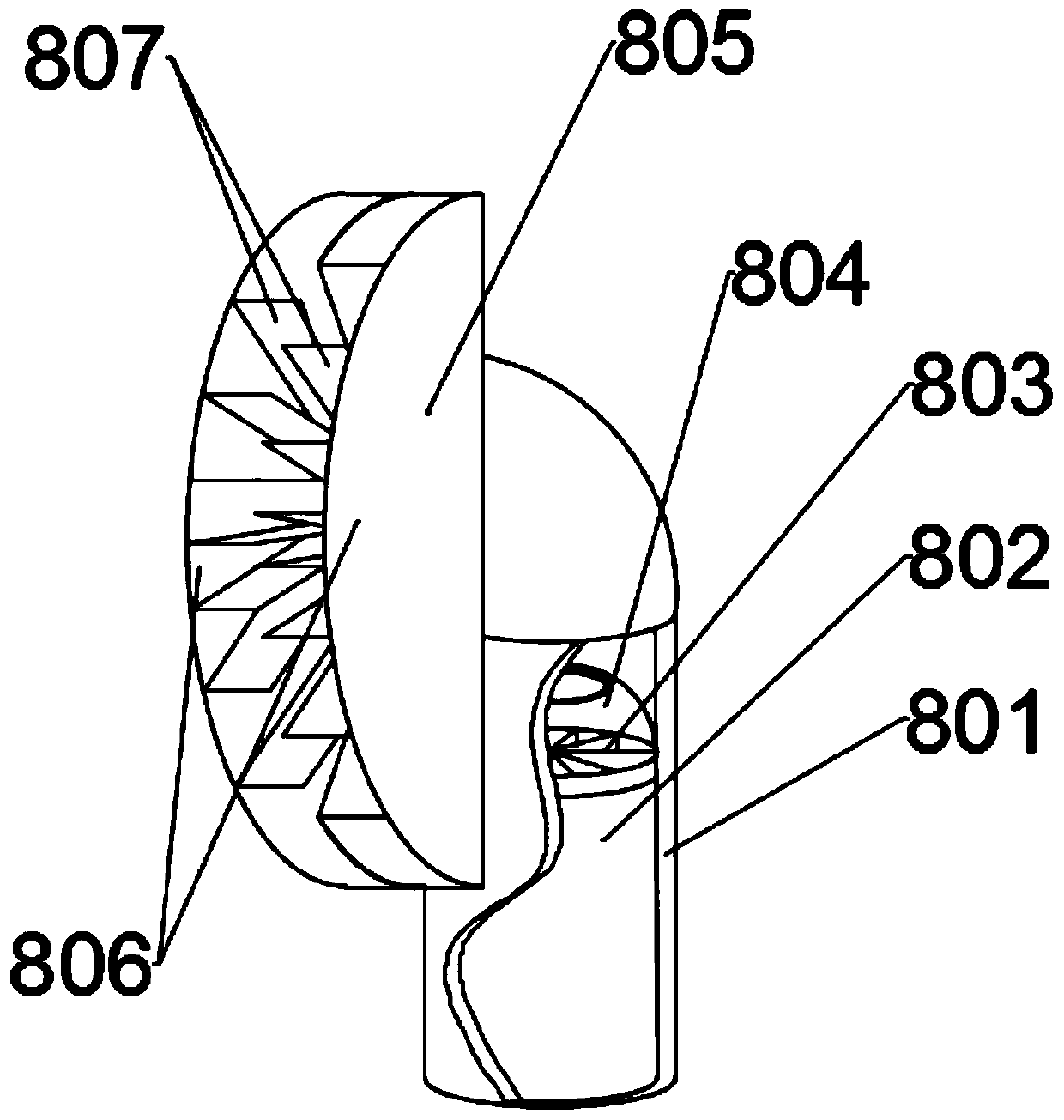

[0052] Such as Figure 1-Figure 3 Shown, the present invention also provides a kind of GR-SiO used in embodiment 1 2 / IIR composite material preparation and spraying device, including base 1 and front roller 2 and rear roller 3 installed on base 1, the integral top of front roller 2 and rear roller 3 is movably installed with a cover plate through pin rod 4 5. The cover plate 5 is located directly above the front roller 2 and the rear roller 3 and is provided with a track groove 6 along the length direction of the cover plate 5. A screw nut assembly 7 is installed in the track groove 6, and the screw nut assembly 7 A liquid injection device is installed on the nut pair, and the bottom of the liquid injection device facing the front roller 2 and the rear roller 3 is provided with a spray nozzle 8, and a drive motor 9 for driving the screw assembly 7 is arranged in the middle of one end of the cover plate 5.

[0053] The liquid injection device includes an outer casing 101 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com