Drying device for algal protein feed preparation

A technology of seaweed protein and drying equipment, which is applied in the direction of drying, drying machine, heating equipment, etc., can solve the problems of product quality decline, low drying efficiency, short processing time, etc., achieve the degree of optimized drying and prolong the residence time , The effect of speeding up the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

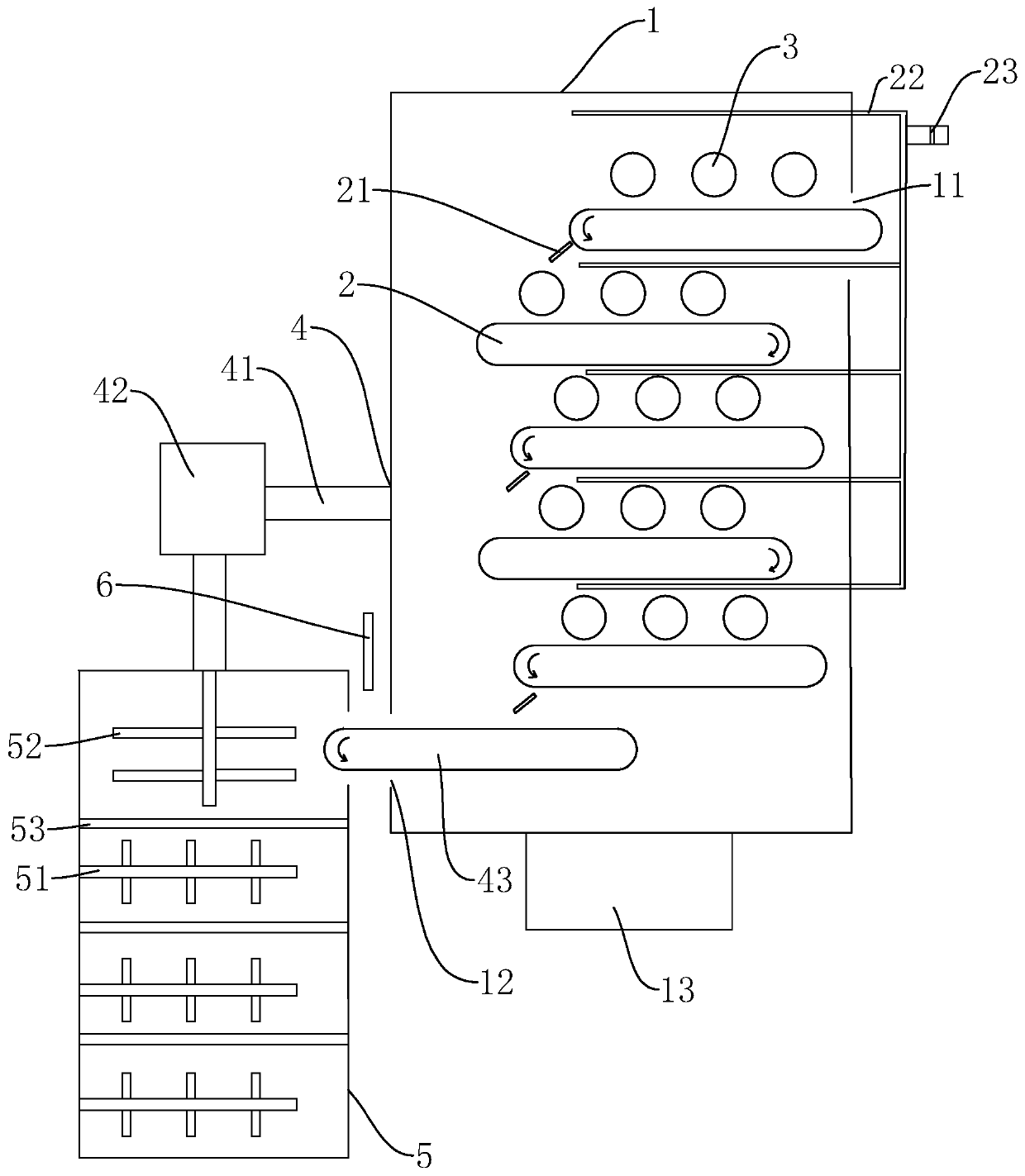

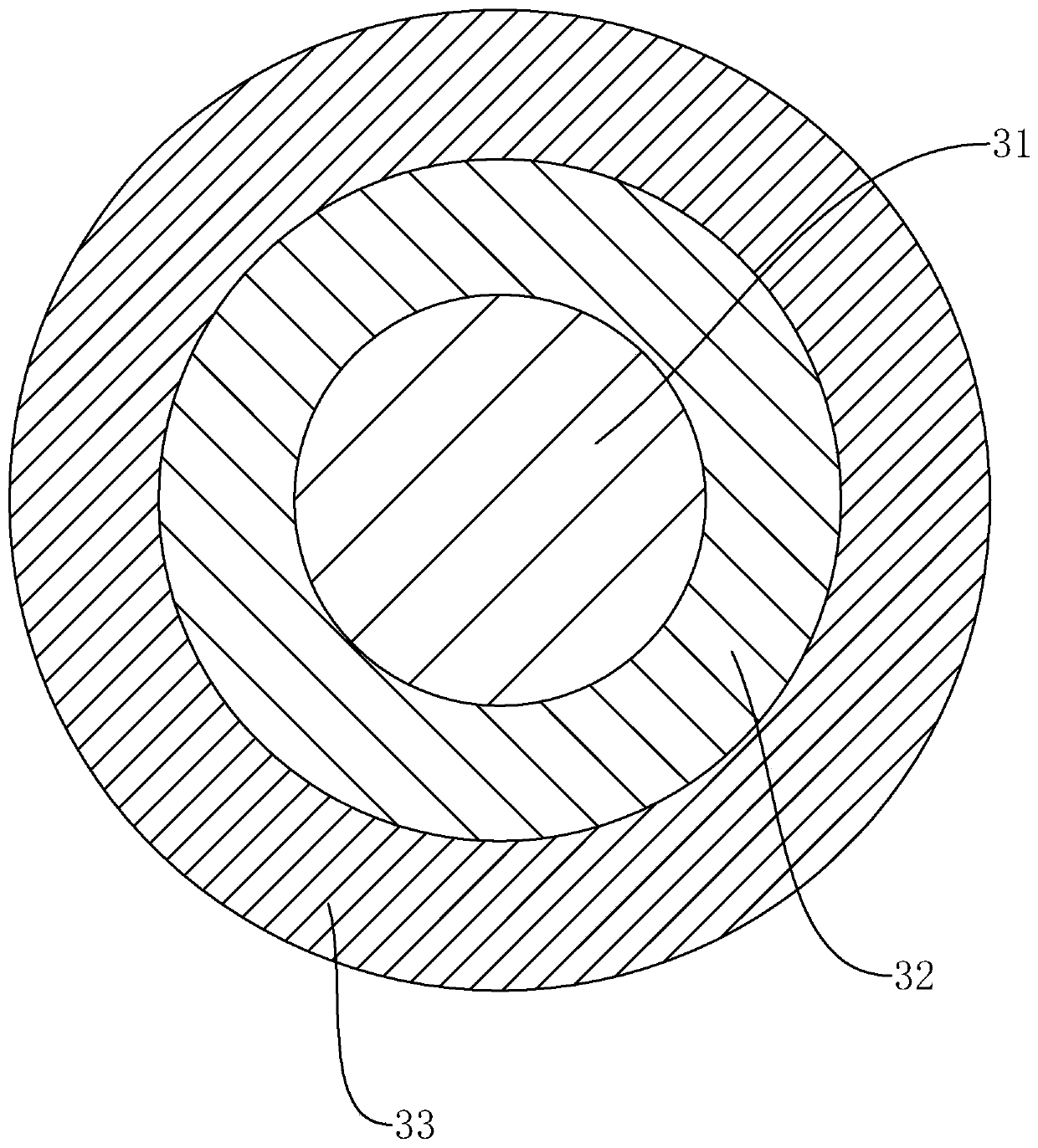

[0023] The invention discloses a drying device for preparing seaweed protein feed, with reference to figure 1 , Including the drying box 1, the drying box 1 is provided with a feed inlet 11 and a material outlet 12, and the drying box 1 is provided with a number of conveyor belts 2 arranged in the horizontal direction, and the conveying list is distributed in the vertical direction. The conveying direction between the two adjacent conveyor belts 2 is opposite. The conveyor belt 2 conveying clockwise shifts to the left, and the conveying belt 2 conveying counterclockwise shifts to the right; each conveying belt 2 is provided with a pressing roller 3 above, and the pressing roller 3 rotates The linear speed is the same as the conveying speed of the conveyor belt 2. The drying box 1 is provided with a scraper 21 under the end of the conveyor belt 2, and the bottom of the drying box 1 is provided with a water collecting box 13; An air supply pipe 22 for blowing air from the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com