Method for preparing slag steam-cured brick

A technology for steam curing bricks and slag, which is applied in manufacturing tools, sustainable waste treatment, solid waste management, etc., can solve the problems of difficult to improve the quality, the problem of water absorption cannot be ignored, and the product effect is not very ideal. Achieve the effect of increasing strength, avoiding land destruction, and protecting cultivated land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

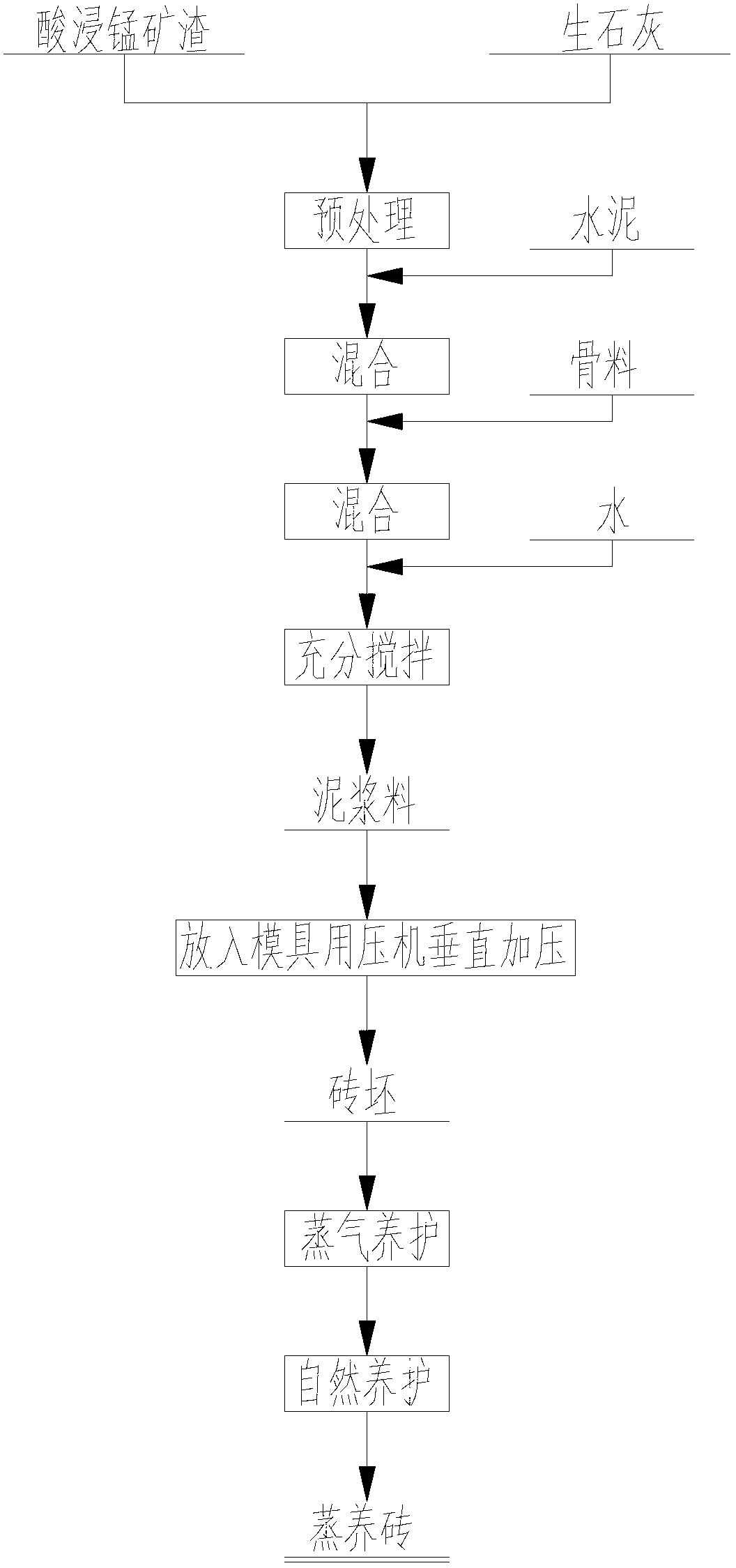

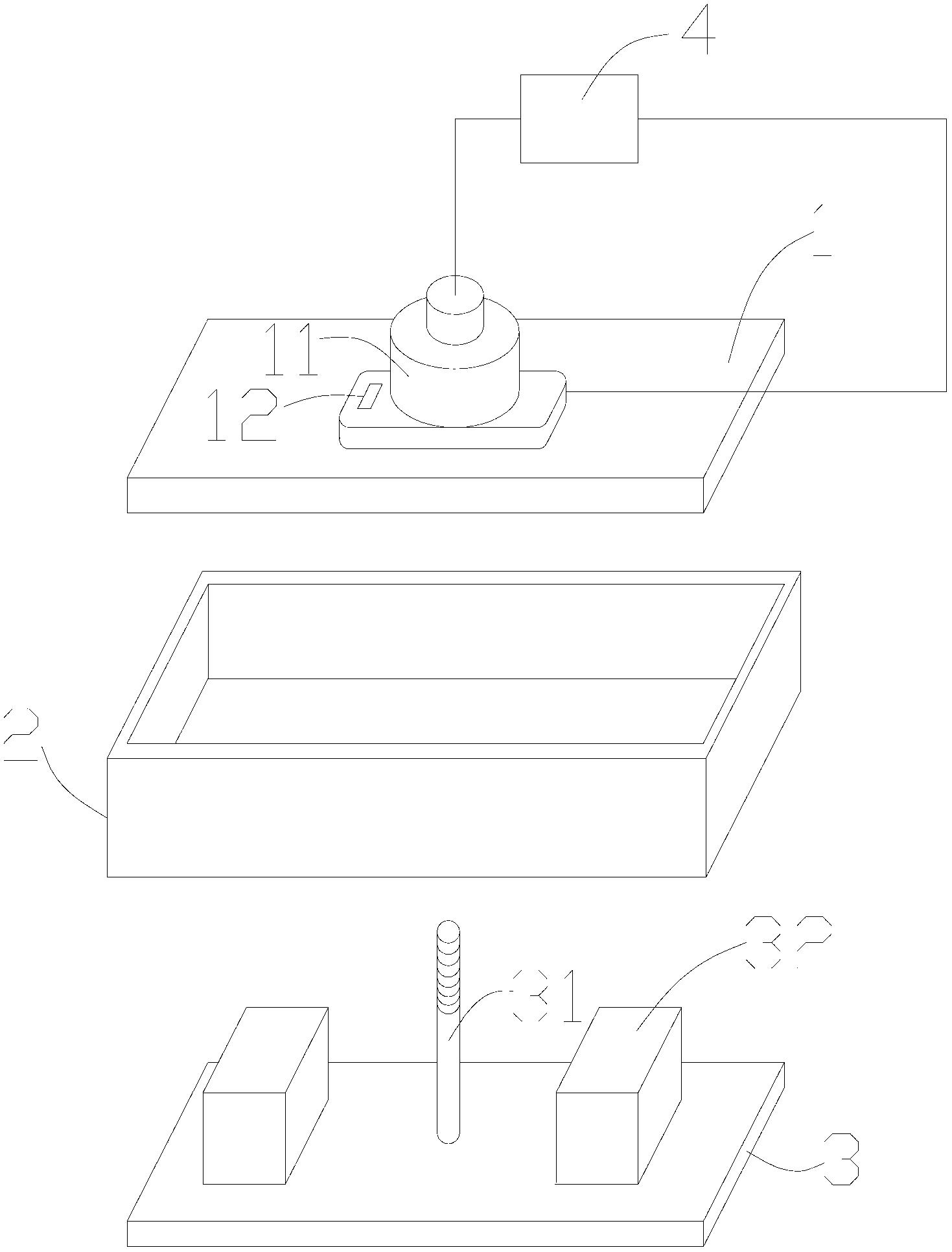

[0028] refer to figure 1 , a kind of slag steam-cured brick preparation method of the present invention, it adopts the following steps: add unslaked lime in proportion to acid leaching manganese slag, acid leaching manganese slag is carried out pretreatment; Pretreated acid leaching manganese slag, cement Mix with aggregate in a certain proportion to obtain a mixture; add water to the final mixture according to a certain water-solid ratio, and stir to obtain a muddy mixture; put the muddy mixture into a self-made mold for preliminary molding, and The preliminarily formed adobe is formed by vertical pressure from top to bottom with the pressure head of an electric hydraulic press, and a high-strength adobe is obtained after holding the pressure for a period of time; the high-strength adobe is placed in a constant temperature water bath for steam curing after being placed for a period of time , control the heating rate, and maintain a constant temperature for a period of time wh...

Embodiment 1

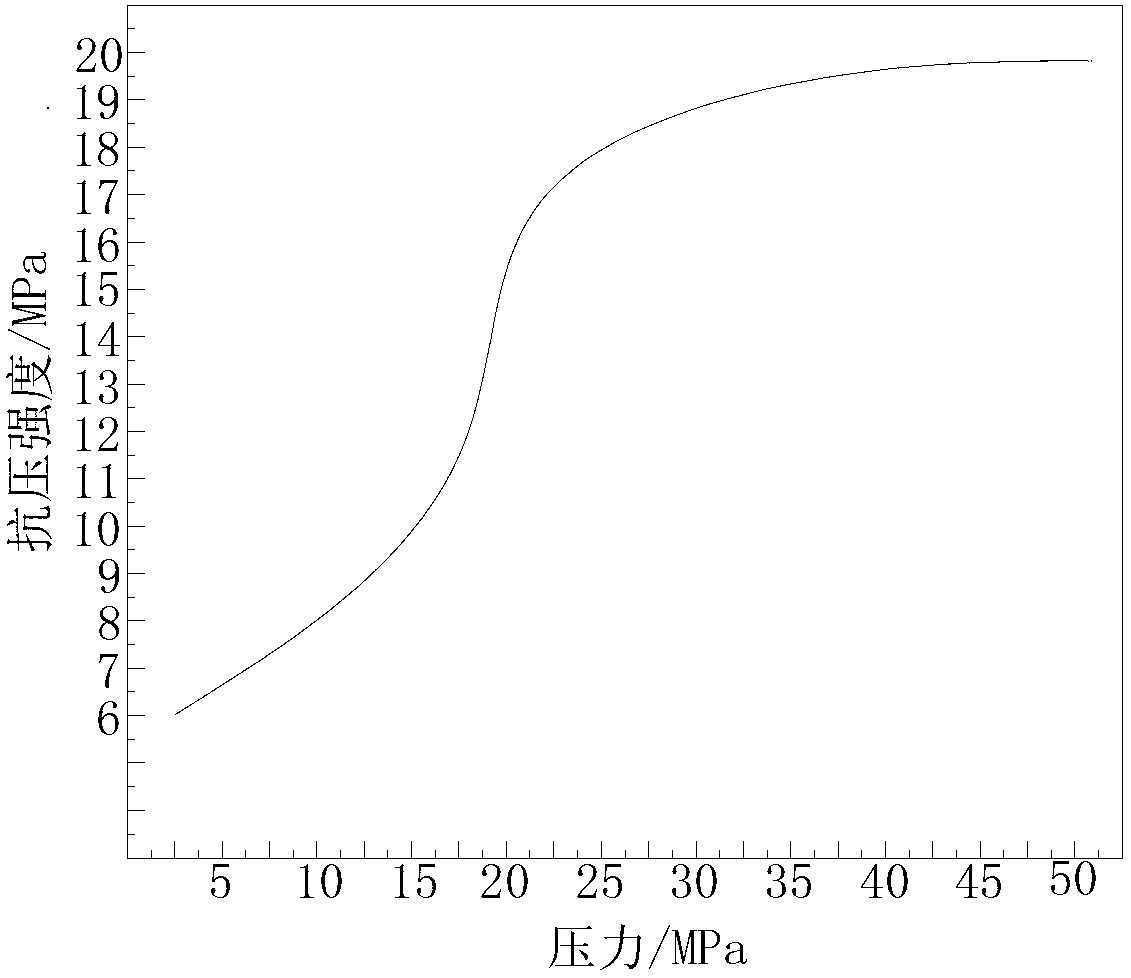

[0048] Weigh 3kg of acid leaching manganese ore waste residue, add 1kg of quicklime to the manganese ore waste residue, the ratio of quicklime to acid leaching manganese ore slag is 1:3, because the acid leaching manganese ore waste residue has a moisture content of about 34.10% and is weakly acidic and contains a small amount of MnSO 4 and (NH 4 ) 2 SO 4 , adding a certain amount of quicklime to pretreat it, the alkaline environment and solidified residual Mn can be obtained 2+ ions while eliminating NH in-process 4+ The impact of release on the environment, add 1.4kg of ordinary Portland cement to the pretreated acid leaching manganese slag, the mixing ratio of cement and pretreated acid leaching manganese slag is 1:3.5, and mix to obtain a preliminary mixture. Considering For industrial application and economic cost, 3.6kg of natural river sand after passing through a 20-mesh sieve is added as aggregate. The aggregate plays the role of skeleton and filling in brick produ...

Embodiment 2

[0050] Take by weighing 4kg acid leaching manganese ore waste residue, add 1kg quicklime in the manganese ore waste residue, the ratio of quicklime and acid leaching manganese slag is 1:4, add ordinary portland cement 0.8kg in the acid leaching manganese slag through pretreatment, cement and The mixing ratio of pretreated manganese leaching manganese slag is 1:6, mix to obtain preliminary mixture, then add 5.2kg of natural river sand after passing through 20-mesh sieve as aggregate, the ratio of preliminary mixture to aggregate is 1:0.9, mix Obtain final mixture, add water 3.3kg in the described final mixture in the ratio of 10:3 by solid-water ratio, carry out sufficient stirring again to obtain muddy mixture, described muddy mixture is put into self-made mould, preliminary molding, The preliminarily formed adobe is then vertically pressurized by the pressure head of an electric hydraulic press, pressurizing 30MPa from one side from top to bottom, and after holding the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com