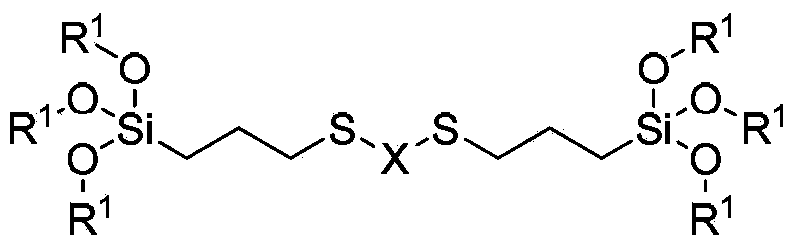

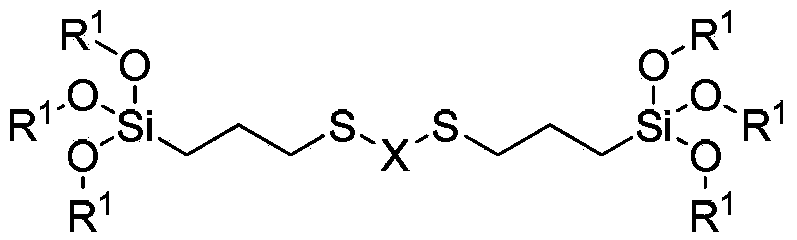

Diacylthioxo silane coupling agent and preparation method thereof

A technology of bisacylthiosilane coupling agent and mercaptopropyltrialkoxysilane, applied in the field of bisacylthiosilane coupling agent and its preparation, achieving the effects of low equipment requirements, reasonable design, and reasonable synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment is implemented according to route one.

[0026] In a dry 2L flask, add 476g (2mol) 3-mercaptopropyltriethoxysilane, add 252.5g (2.5mol) anhydrous triethylamine, add 200mL anhydrous toluene to dilute, start mechanical stirring, after mixing evenly, 127 g (1 mol) of oxalyl chloride was slowly added dropwise from the constant pressure dropping funnel, and a large amount of white insoluble precipitate was formed immediately. After 30 minutes, the dropwise addition was completed. After stirring for 2 hours, the precipitate was removed by filtration, and triethylamine and toluene were removed by distillation under reduced pressure. , obtain a light yellow viscous liquid, slightly turbid, after filtering once, remove low boiling under reduced pressure, obtain 659g light yellow transparent viscous liquid, namely the product oxalyl-bis-[triethoxysilylpropyl sulfur ], the yield is 98%. Through gas chromatography analysis, the content of the two raw materials has ...

Embodiment 2

[0028] This embodiment is implemented according to the second route.

[0029] 1) Prepare an aqueous solution of sodium dithioadipate. In a 2L three-necked flask, add 240g (1mol) of solid sodium sulfide nonahydrate, add 150g of water, and dissolve to obtain a sodium sulfide solution with a concentration of 20%. Press the dropping funnel and drop it in about 20 minutes. With the dropping of adipoyl chloride, the temperature in the bottle will rise to about 70 °C, keep stirring, and cool the system to room temperature naturally to obtain a slightly viscous transparent Aqueous sodium dithioadipate solution.

[0030] 2) Preparation of adipyl-bis-[triethoxysilylpropyl sulfide]. Add 3g saturated tetrahexylammonium chloride solution to the solution prepared in step 1), under mechanical stirring, drop 240g (1mol) 3-chloropropyltriethoxysilane from the constant pressure dropping funnel, within 15 minutes The dropwise addition was completed, after completion, the temperature was raise...

Embodiment 3

[0032] This embodiment is implemented according to route one.

[0033] Add 238 g (1 mol) of 3-mercaptopropyl triethoxysilane to a dry 2 L flask, add 50 mL of anhydrous tetrahydrofuran to dilute, take 101.5 g (0.5 mol) of terephthaloyl chloride and dissolve it in 200 mL of anhydrous tetrahydrofuran. The constant pressure dropping funnel was slowly added dropwise. Under mechanical stirring, the generated hydrogen chloride was discharged with nitrogen. After 30 minutes, the dropwise addition was completed. The stirring was maintained for 2 hours, and the toluene was distilled off under reduced pressure. At this time, the pH value of the system was about 4. Add 5 g After neutralization with sodium ethoxide, filter to obtain light yellow viscous liquid, remove low boiling under reduced pressure to obtain 294g light yellow transparent viscous liquid, which is the product phthaloyl-bis-[triethoxysilylpropyl sulfide] ], the yield is 97%. Gas chromatography analysis showed that the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com