Method for recovering sulfur from byproduct of acid gas generated in production of rubber chemicals

A technology of rubber additives and acid gas, applied in the direction of sulfur preparation/purification, etc., can solve problems such as unsatisfactory catalytic effect, side reactions, and large steam consumption, and achieve advanced and mature process routes, large load elasticity, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

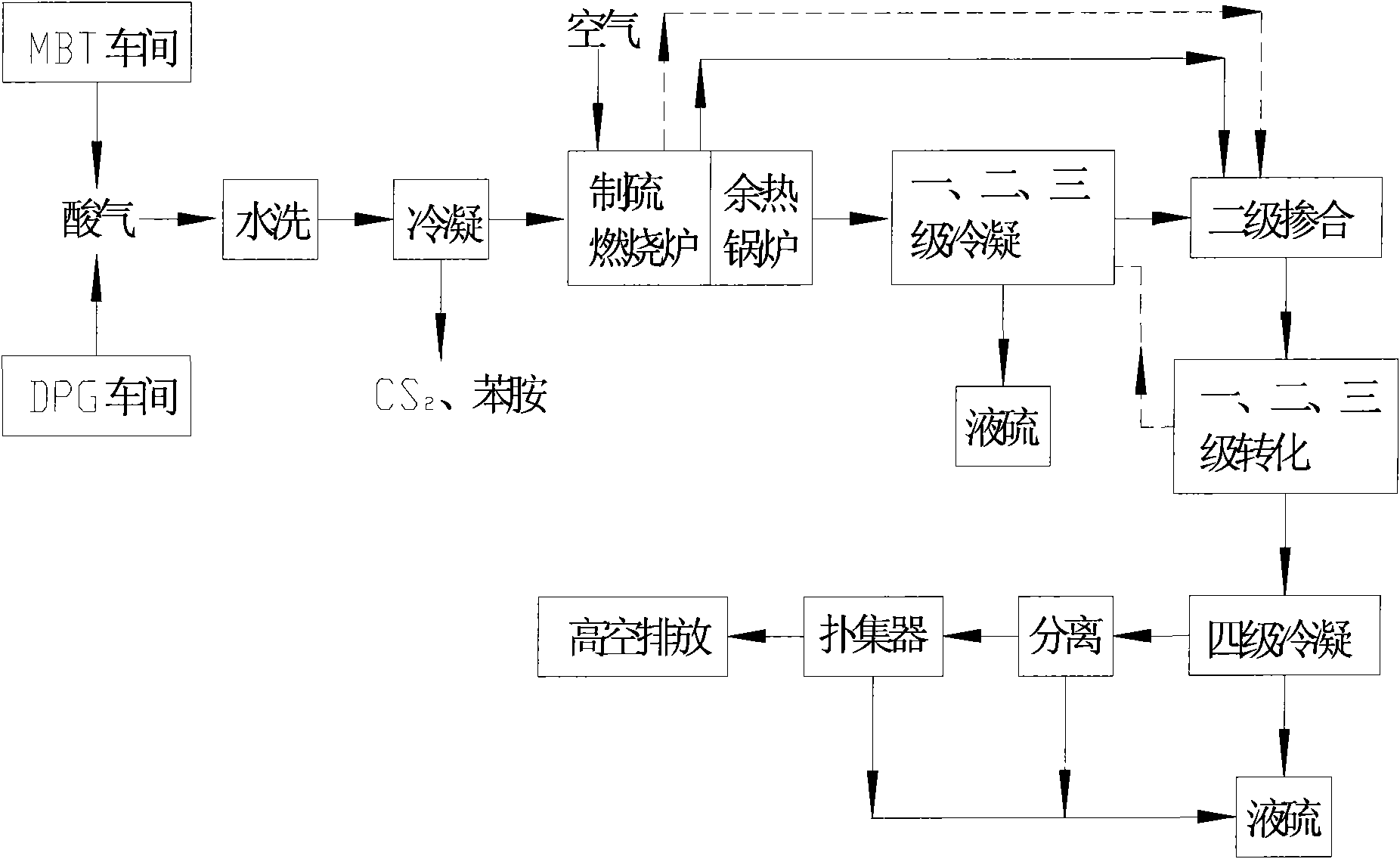

[0030] As shown in the accompanying drawings, a specific embodiment of the present invention is as follows:

[0031] The acid gas from the accelerator MBT workshop and DPG workshop enters the carbon disulfide recovery condensing cooler after being washed with water to recover carbon disulfide, aniline and benzothiazole in the raw gas, and the recovered materials are returned to the workshop to participate in the reaction, recycled and reused, and then All the acid gas is introduced into the combustion furnace for sulfur production, and in the combustion furnace for sulfur production, the O 2 Strictly control the air distribution ratio, so that H 2 S burns to produce SO 2 The amount satisfies H 2 S / SO 2 Close to the theoretical value 2, H 2 S and SO 2 A high-temperature thermal reaction occurs in the furnace to generate gaseous sulfur. The reaction temperature in the sulfur furnace is 800-1250°C to partially burn hydrogen sulfide to generate sulfur dioxide and water, and ...

Embodiment 2

[0034] Concrete steps of the present invention are as follows:

[0035] (1) The acid gas from the upstream workshop is washed and condensed to recover carbon disulfide, aniline, and benzothiazole, and the recovered materials are returned to the upstream workshop for recycling;

[0036] (2) The acid gas after condensing and cooling to recover carbon disulfide is separated from the acid water by the acid gas separator tank, and then preheated by the steam heat tracing pipe, then enters the sulfur making combustion furnace and the air sent by the Roots blower is adjusted by the ratio and The feedback data of the exhaust gas online analyzer realizes the cascade adjustment of the air distribution, so that the amount of sulfur dioxide generated by the combustion of hydrogen sulfide meets the requirements of H 2 S / SO 2 Close to 2:1; hydrogen sulfide and sulfur dioxide undergo a high-temperature thermal reaction under the action of a catalyst to generate elemental sulfur and water; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com