Modified nature latex, preparation method and use thereof

A natural latex and modification technology, applied in the field of preparation of modified natural latex, can solve the problems of high cost, reduced mechanical properties of latex products, complicated processes, etc. good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

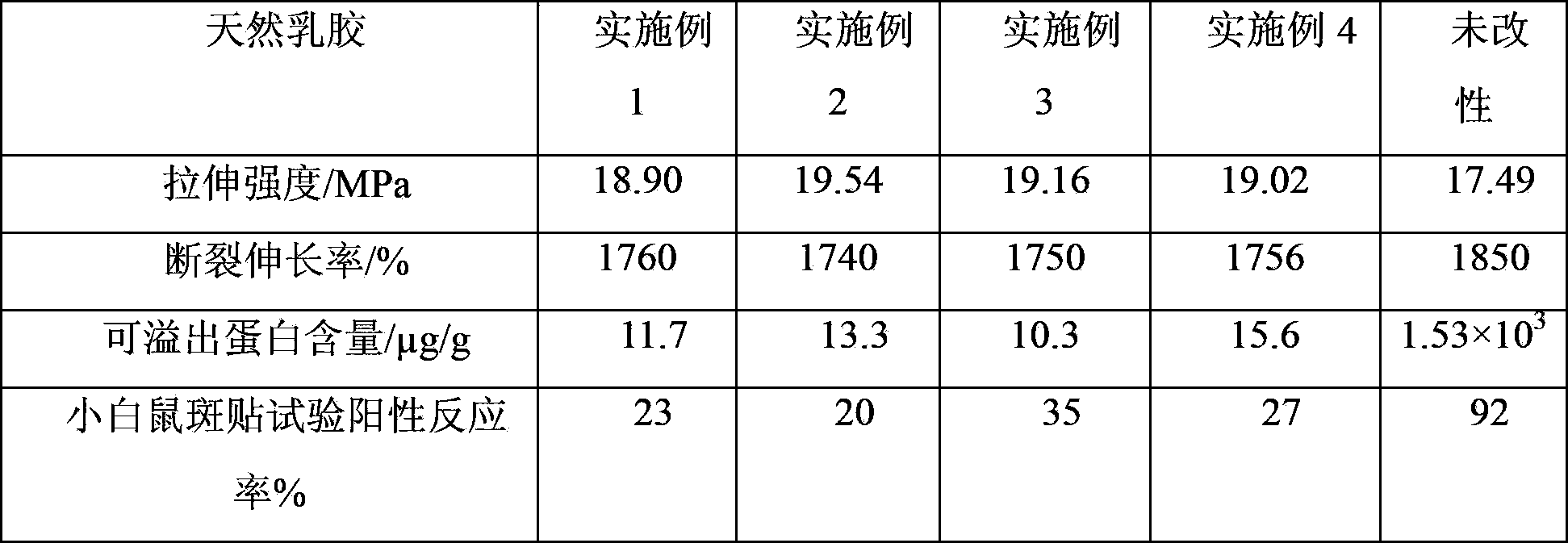

Examples

Embodiment 1

[0051] (1) Preparation of sericin aqueous solution:

[0052] Cut commercially available cocoons into about 0.5cm 3 After the block, weigh 50 parts and wash with shaking water, then rinse with deionized water;

[0053]After washing, add 300 parts of deionized water, put it into a flask for a 100°C water bath, and keep boiling for 3 hours after boiling, then stop heating;

[0054] After hot suction filtration, the resulting solution was freeze-dried at -30°C for 24 hours to obtain 13.5 parts of sericin powder;

[0055] Add 100 parts of deionized water to 13.5 parts of sericin powder, stir evenly for 10 minutes (stirring speed is 150r / min) to fully dissolve, and obtain a sericin aqueous solution with a concentration of 11.9%, and set aside;

[0056] (2) Preparation of sericin grafted water-based polyurethane emulsion:

[0057] In the four-necked flask equipped with agitator, thermometer, reflux condenser and dropping funnel, drop into oligomer polyol polypropylene glycol 2000 ...

Embodiment 2

[0065] (1) Preparation of sericin aqueous solution:

[0066] Cut commercially available cocoons into about 1.0cm 3 After the block, weigh 50 parts and wash with shaking water, then rinse with deionized water;

[0067] After washing, add 400 parts of deionized water, put it into a flask for a 105°C water bath, and keep boiling for 4 hours after boiling, then stop heating;

[0068] After hot suction filtration, the resulting solution was freeze-dried at -40°C for 18 hours to obtain 14.3 parts of sericin powder;

[0069] Add 100 parts of deionized water to 14.3 parts of sericin powder, stir evenly for 10 minutes (stirring speed is 200r / min) to fully dissolve, and obtain a sericin aqueous solution with a concentration of 12.5%, and set aside;

[0070] (2) Preparation of sericin grafted water-based polyurethane emulsion:

[0071] In the four-necked flask equipped with stirrer, thermometer, reflux condenser and dropping funnel, drop into oligomer polyol polytetrahydrofuran ether ...

Embodiment 3

[0078] (1) Preparation of sericin aqueous solution:

[0079] Cut commercially available cocoons into about 1.5cm 3 After the block, weigh 70 parts and wash with shaking water, then rinse with deionized water;

[0080] After washing, add 500 parts of deionized water, put it into a flask for a 110°C water bath, and stop heating after boiling for 3.5 hours;

[0081] After hot suction filtration, the resulting solution was freeze-dried at -50°C for 12 hours to obtain 20.9 parts of sericin powder;

[0082] Add 100 parts of deionized water to 20.9 parts of sericin powder, stir evenly for 10 minutes (stirring speed is 250r / min) to fully dissolve, and obtain a sericin aqueous solution with a concentration of 17.3%, and set aside;

[0083] (2) Preparation of sericin grafted water-based polyurethane emulsion:

[0084] In a four-necked flask equipped with a stirrer, a thermometer, a reflux condenser and a dropping funnel, drop into 35.07 parts by weight of oligomer polyol polyoxypropy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com