Method for treating rubber chemical wastewater by microwave enhanced microelectrolysis combined oxidation

A technology of rubber additives and oxidation treatment, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of heavy economic burden, high cost per ton of water, high investment, etc., and achieve investment and operation The effect of low cost, reduced speculation, and increased removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

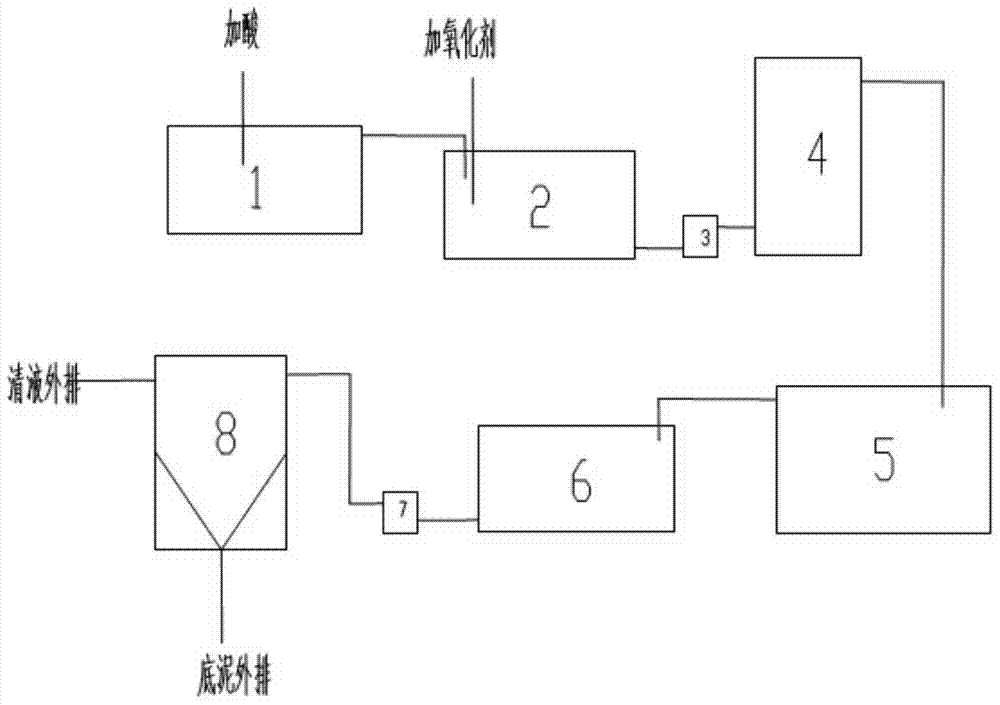

Image

Examples

Embodiment 1

[0048] COD7500mg / L, pH: 8.5 of a rubber auxiliary wastewater. First carry out acidification reaction treatment, add sulfuric acid to adjust the pH: 3.0, and react for 5 minutes. At this time, the COD of the rubber additive wastewater after acidification is 7300mg / L; mg / L, reacted for 30 minutes, pH: 3.0, the COD of the oxidized rubber additive wastewater is 7000 mg / L, pH: 3.0; the oxidized wastewater enters the micro-electrolysis reactor for reaction, and the gas-water ratio is 20:1 Air is introduced, the reaction time is 120 minutes, the COD of the rubber additive wastewater after the micro-electrolysis reaction is 4500 mg / L, pH: 5.5; the rubber additive mixed wastewater after the micro-electrolysis reaction enters the microwave reactor for reaction, and the microwave power 600W, the treatment time is 10 minutes, the pH of the rubber additive wastewater after microwave reaction: 5.5, COD3000 mg / L; the rubber additive wastewater after microwave reaction enters the neutralizati...

Embodiment 2

[0050] COD6500mg / L, pH: 8.5 of a rubber additive wastewater. First carry out acidification reaction treatment, add sulfuric acid to adjust the pH: 3.0, and react for 5 minutes. At this time, the COD6300mg / L of the rubber additive wastewater after acidification; add hydrogen peroxide 6300 into the wastewater after acidification according to the ratio of hydrogen peroxide to wastewater 1:1 mg / L, reacted for 30 minutes, pH: 3.0, COD6000 mg / L of the oxidized rubber additive wastewater, pH: 3.0; the oxidized wastewater enters the micro-electrolysis reactor for reaction, according to the gas-water ratio of 15:1 Air is introduced, the reaction time is 70 minutes, the COD of the rubber additive wastewater after the micro-electrolysis reaction is 4500mg / L, pH: 5.5; the rubber additive mixed wastewater after the micro-electrolysis reaction enters the microwave reactor for reaction, and the microwave power is 500W , the treatment time is 10 minutes, the pH of the rubber additive wastewat...

Embodiment 3

[0052] A certain rubber additive wastewater is treated with a method of the present invention that uses microwave-enhanced micro-electrolysis combined oxidation to treat rubber additive wastewater. COD6000mg / L, pH: 8.0 of a rubber additive wastewater. First, carry out acidification reaction treatment, add sulfuric acid to adjust the pH: 3.0, and react for 5 minutes. At this time, the COD of the rubber additive wastewater after acidification is 5800mg / L; the ratio of hydrogen peroxide to wastewater after acidification is 1:1, add hydrogen peroxide 5800mg / L, reacted for 30 minutes, pH: 3.0, COD5500mg / L of the oxidized rubber additive wastewater, pH: 3.0; the oxidized wastewater enters the micro-electrolysis reactor for reaction, and the gas-water ratio is 15:1. Air, the reaction time is 100 minutes, COD3500mg / L, pH: 5.5 of the waste water of rubber additives after the micro-electrolysis reaction; the mixed waste water of rubber additives after the micro-electrolysis reaction en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com