Wet natural rubber compound and producing process thereof

A technology of solid natural rubber and natural rubber latex, which is applied in the field of rubber technology and production engineering, and can solve problems such as dispersion of difficult chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

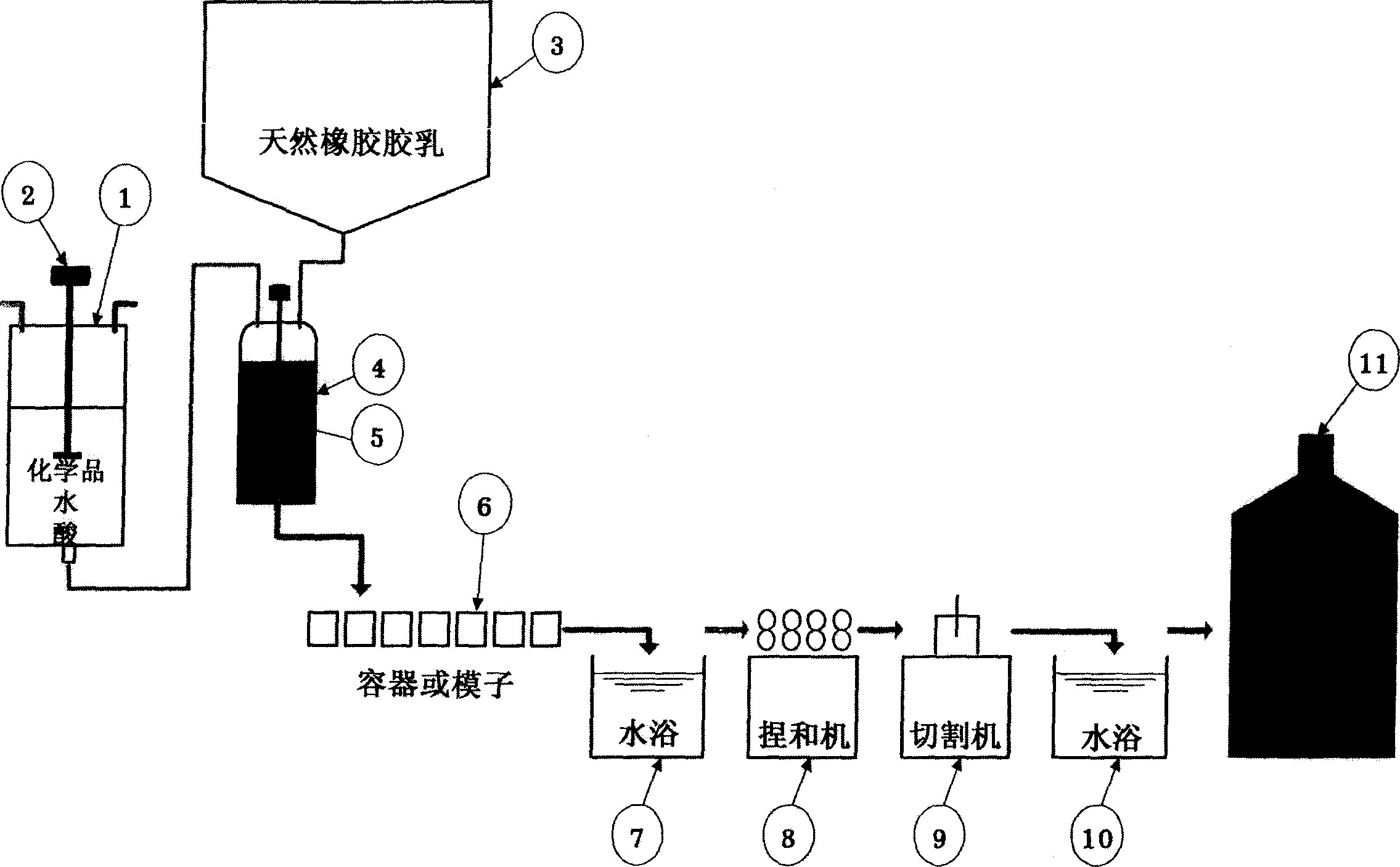

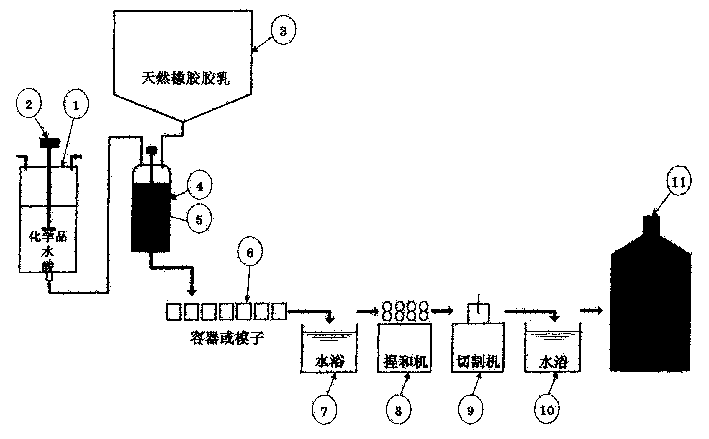

Method used

Image

Examples

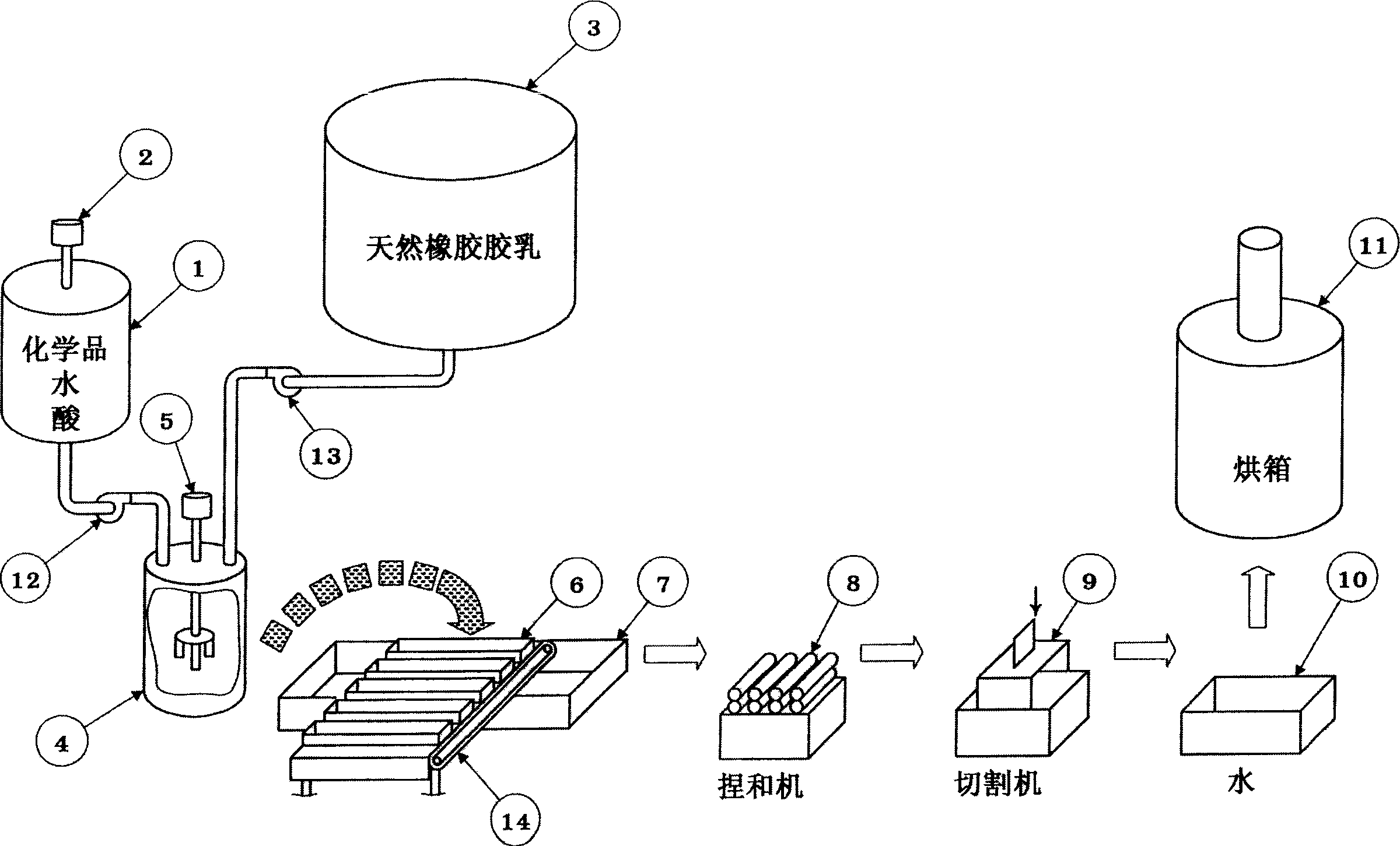

Embodiment 1

[0027] In order to produce 4.5kg masterbatch containing 50 parts of silica per 100 parts of natural rubber, the raw materials are:

[0028] 1. Water 9kg

[0029] 2. 90% formic acid 0.015kg (15g)

[0030] 3. Silica 1.5kg

[0031] 4. 30% latex solids 10kg

[0032] The procedure is exactly as described above, but the mixing and setting steps, which are the main object of the invention, will be explained in more detail. refer to figure 2 Described equipment, 9kg water and 0.015kg formic acid are poured into mixing tank 1. Then 3 kg of silica were transferred into the same tank. Thoroughly mix the water and silica to a pH in the range of 3.5-5.0 and then transfer the mixture to the mixing tank 4 using the pump 12 . The mixture was thoroughly stirred again with the slow mixer 5 and 10 kg of latex from tank 3 were added to the mixture tank 4 within a few minutes. After stirring for 2-3 minutes, pour the wet compound into stainless steel molds and start to set. Coagulation wi...

Embodiment 2

[0034] In order to produce 15kg of masterbatch with 400 parts of sulfur per 100 parts of natural rubber, the raw materials are:

[0035] 1. Water 19kg

[0036] 2. 90% formic acid 0.018kg (18g)

[0037] 3. Sulfur 12kg

[0038] 4. 30% latex solids 10kg

[0039] Pour 19 kg of water and 0.018 kg (18 g) of formic acid into mixing tank 1 . 12 kg of sulfur was then added to the same tank. The total weight of the mixture after sulfur addition was 31.018 kg. After thoroughly mixing the water, acid and sulfur mixture using a mixer, check and adjust the pH of the mixture within the range of 3.5-5.0. A pump 12 is used to transfer the mixture to a mixing tank 4 equipped with a low speed agitator 5 . Stir the mixture thoroughly again, add 10 kg of latex to the sulfur powder and dilute formic acid mixture, and stir until all components are thoroughly mixed. The wet compound is then transferred to mold 6 . Wait 30 minutes to complete the setting process. Wash and compress the rubber ...

Embodiment 3

[0041] In order to produce 6kg of masterbatch, every 100 parts of natural rubber contains 100 parts of carbon black, and the raw materials are:

[0042] 1. Water 9kg

[0043] 2. 90% formic acid 0.015kg (15g)

[0044] 3. Carbon black 3kg

[0045] 4. 30% latex solids 10kg

[0046]Pour 9 kg of water and 0.015 kg (15 g) of formic acid into mixing tank 1 . 3 kg of carbon black was then added to the same tank. The total weight of the mixture after addition of carbon black was 12.015 kg. After thoroughly mixing the water, acid and sulfur mixture using a mixer, check and adjust the pH of the mixture within the range of 3.5-5.0. A pump 12 is used to transfer the mixture to a mixing tank 4 equipped with a low speed agitator 5 . Stir the mixture thoroughly again, add 10 kg of latex to the carbon black powder and dilute formic acid mixture, and stir until all components are thoroughly mixed. The wet compound is then transferred to mold 6 . Wait 30 minutes to complete the setting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com