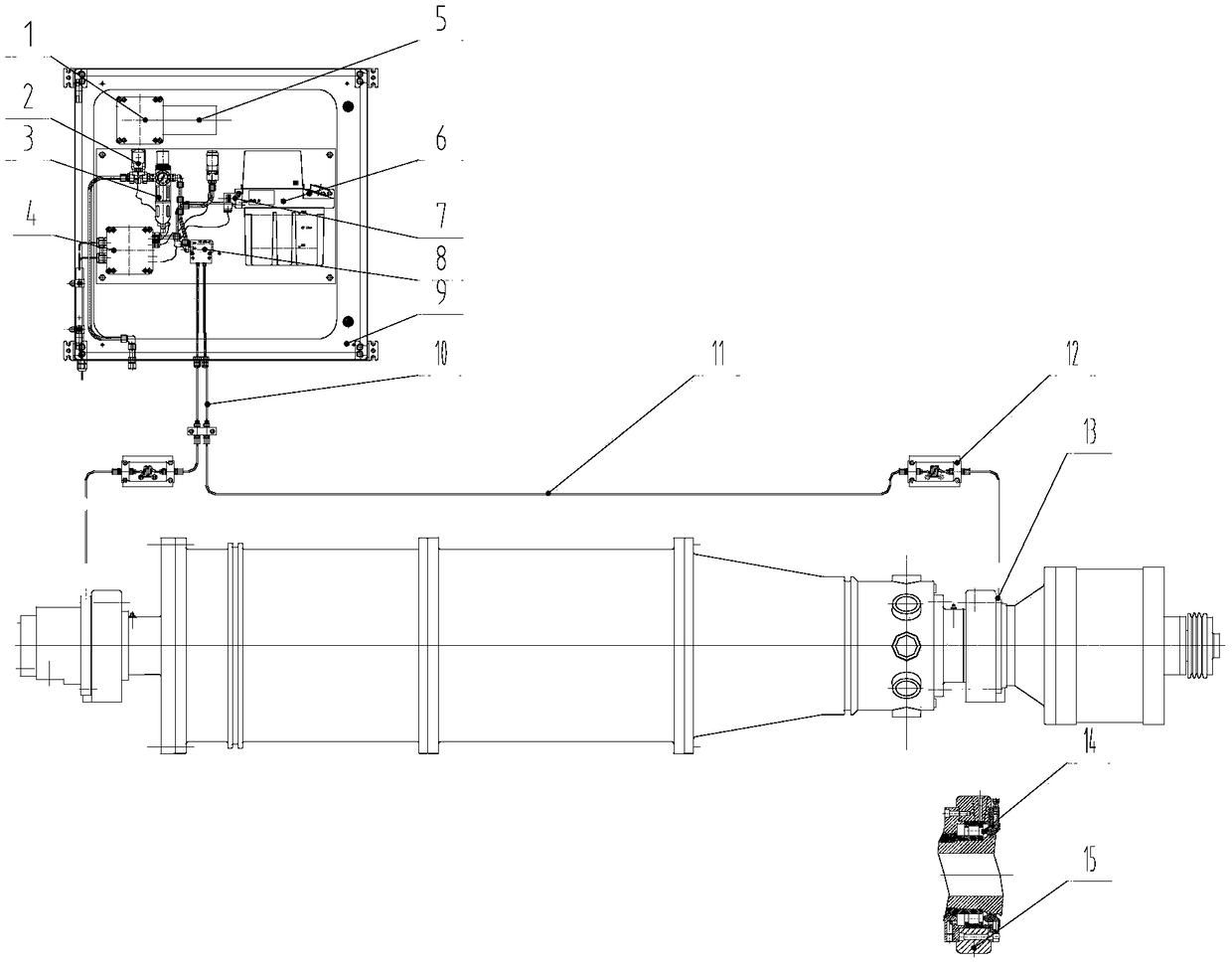

Trace air-oil lubrication system of horizontal decanter screw centrifuge

A technology of oil-air lubrication and horizontal screw machine, which is applied in the direction of engine lubrication, lubricating parts, mechanical equipment, etc. It can solve problems such as many fault points, oil pollution, and complex systems, and achieve low production costs, reasonable layout, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The invention provides a micro oil-air lubrication system of a horizontal screw machine, such as figure 1 Shown: a micro oil-air lubrication system for a decanter machine, the micro oil-air lubrication system is installed around the body of the decanter machine through pipelines, including the box. A controller powered by a DC power supply is installed inside the box, and an oil circuit control system and an air circuit control system are respectively provided below the controller, both of which are connected to the oil and gas distributor through lines; the oil circuit control system includes A lubricating oil tank, an oil pump is installed inside the lubricating oil tank, and the oil pump is as figure 1 As shown, the oil outlet is connected to the inlet of the oil-air distributor marked with oil through the line; the air circuit control system includes: the compressed air is first filtered and decompressed, and then reaches the oil-air distributor through the solenoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com