Pneumatic/electric torque spanner dynamic calibrating installation

A verification device, wrench technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., to achieve the effect of enhancing device function, good effect, solving drive and verification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

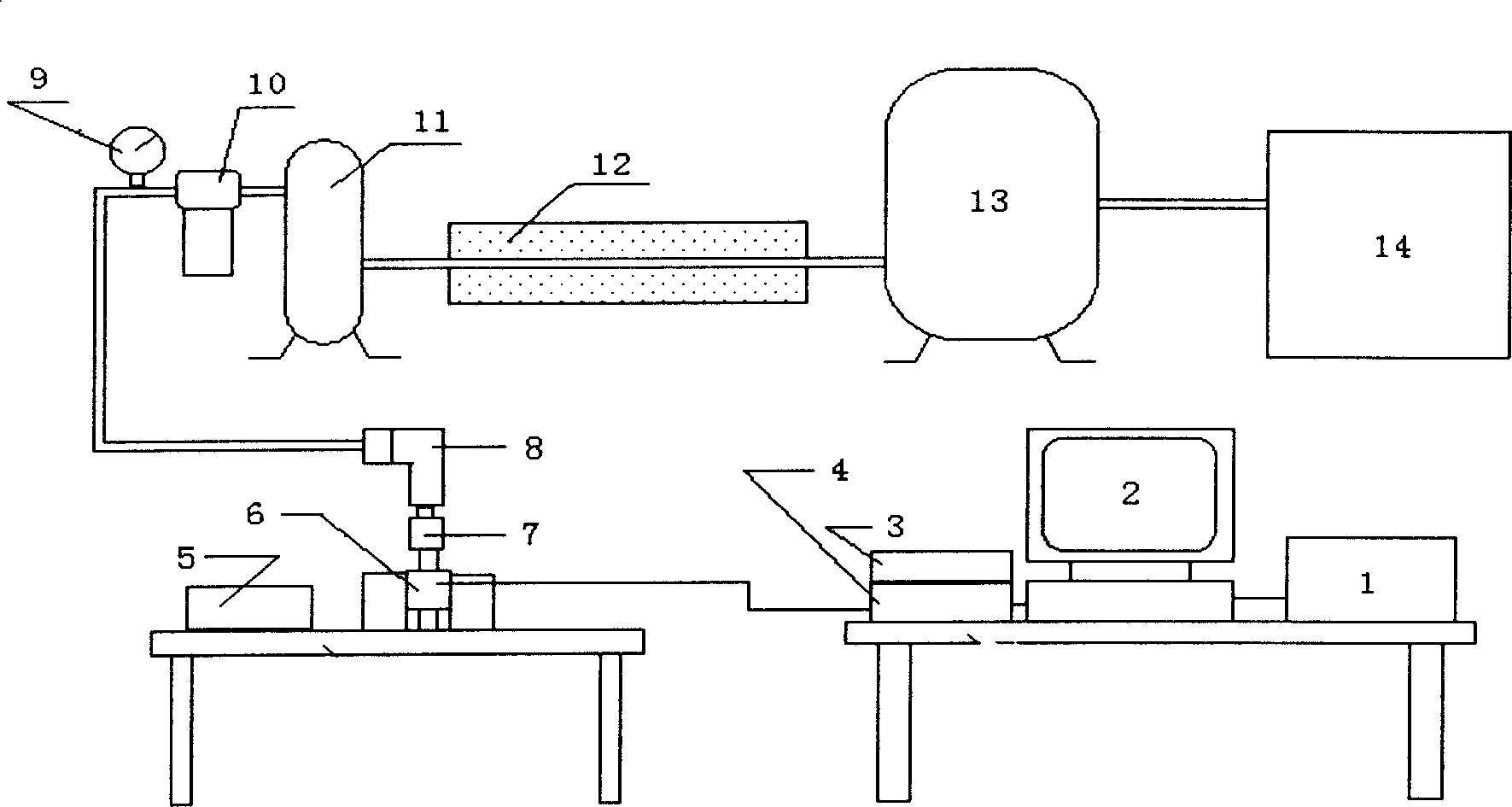

[0016] see figure 1 , Pneumatic / electric torque wrench dynamic verification device is composed of loading power source, flexible buffer, strain-type torque sensor and measurement output system. The loading power source is composed of a scroll air compressor 14, an air tank 13, an oil-water purifier 11, a compressed air filter 10, a precision pressure gauge 9 and a stabilized power supply 5. Among them, the scroll air compressor 14, the air storage tank 13, the oil-water purifier 11 and the compressed air filter 10 are connected in sequence by the air pipe to form a whole, the precision pressure gauge 9 is installed on the pipeline, the condenser 12 is located behind the air storage tank 13, and the built-in Condensate through which the air pipes pass. The tested torque wrench (pneumatic) 8 is connected to the end of the pipeline. If the electric torque wrench is to be measured, the gas tank 13 regulated power supply is directly connected to the tested electric torque wrench. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com