Compressed air filter

A compressed air and filter technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as unsatisfactory treatment effects, improve filtration efficiency and effect, stabilize filtration effect, and increase cooling area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

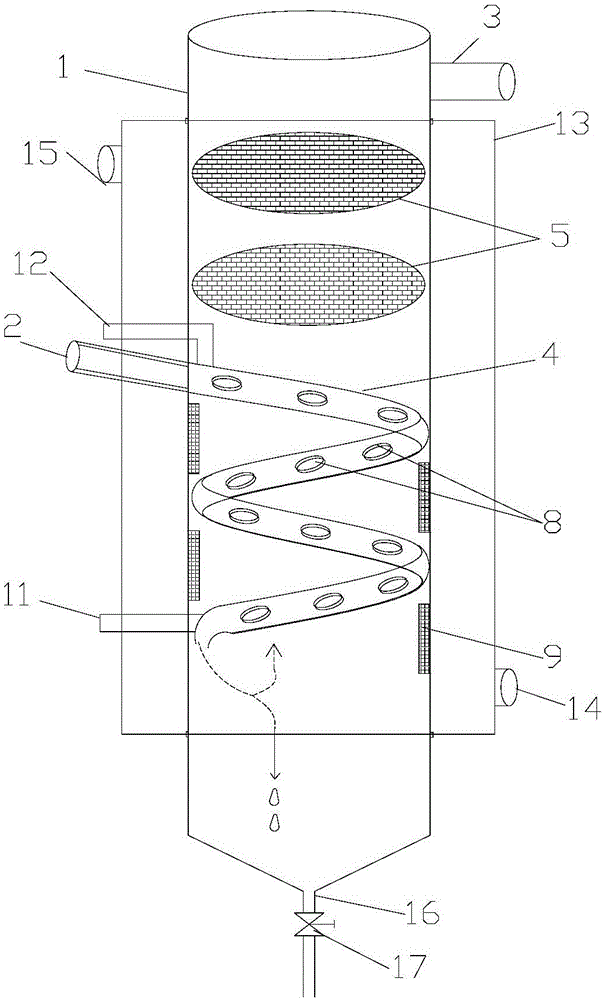

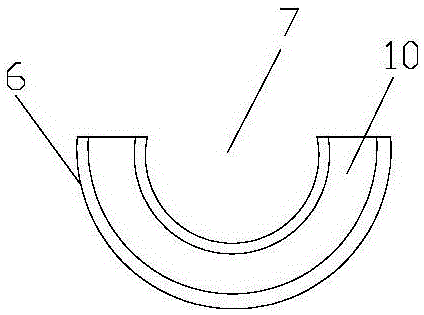

[0017] see figure 1 , figure 2 , this embodiment includes a cylinder body 1, which is provided with an air inlet pipe 2 and an air outlet pipe 3, the air inlet pipe 2 is inclined downward and backward, and intersects with the wall of the cylinder body to form an angle, and the cylinder body is provided with a spiral spiral The diversion groove 4 is a semi-open groove, the inlet end of which is connected to the air intake pipe 2, and the cylindrical body 1 is also provided with a multi-layer filter screen 5. The air intake pipe 2 is connected with the diversion groove 4 in a tangential line, and can guide the direction of the compressed air entering through the air intake pipe; the included angle between the air intake pipe 2 and the axis of the cylinder body 1 is 110-140°. The shape of the diversion groove cross section 6 is an arc with an opening, such as U-shape, a circle with an opening, an ellipse with an opening, etc., and the notch 7 of the spiral is always facing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com