Patents

Literature

65results about How to "Increase the collision force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

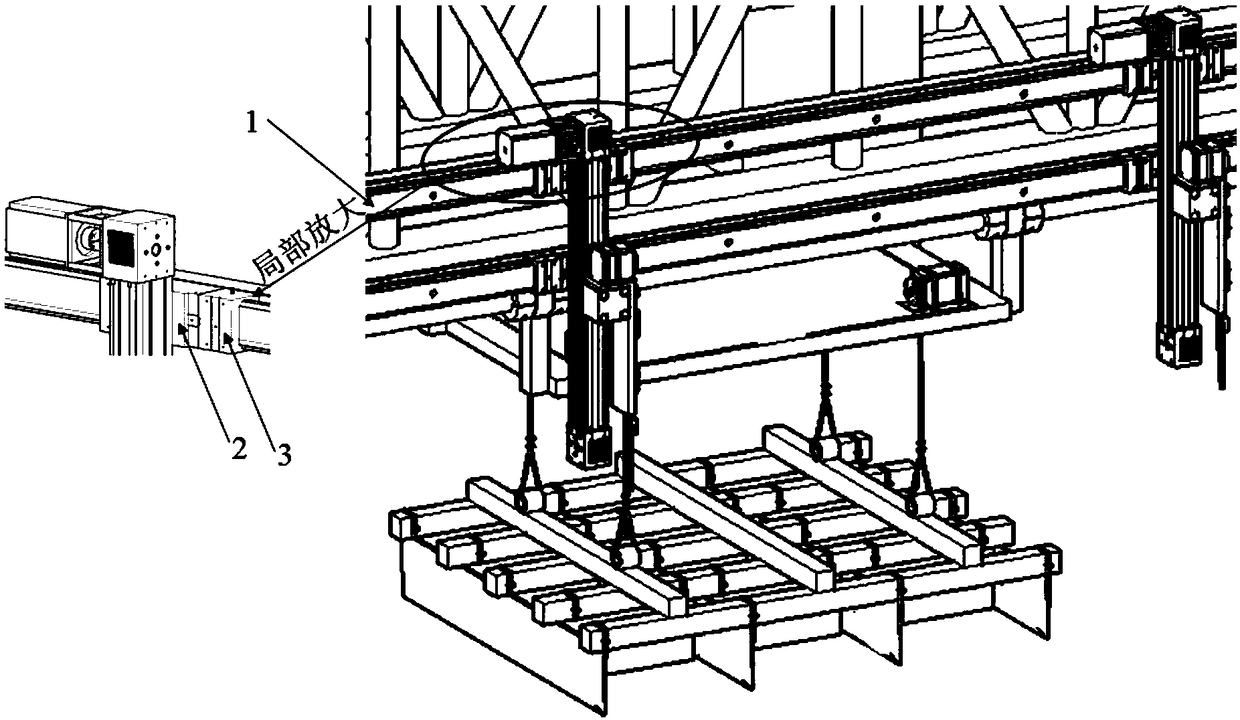

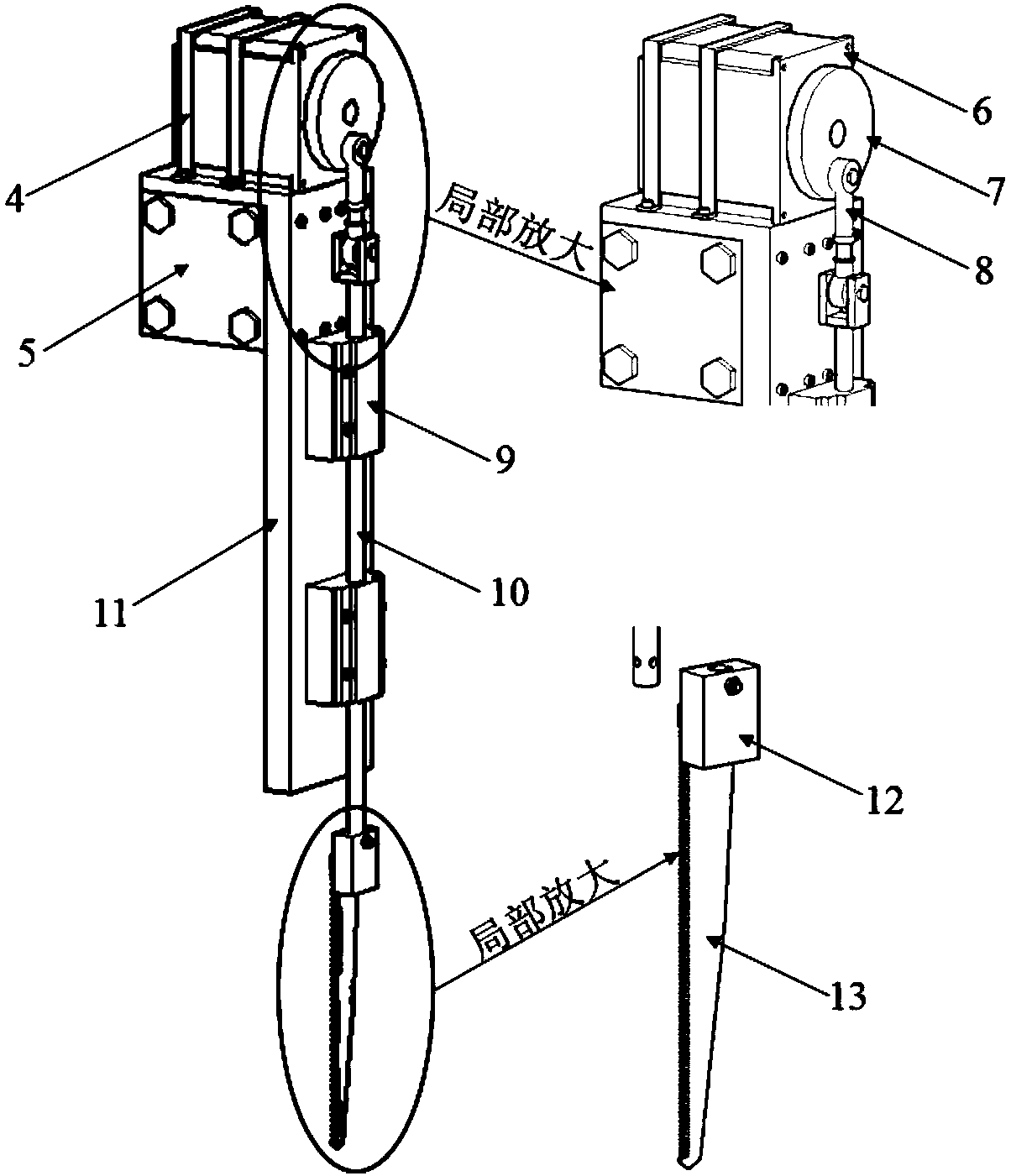

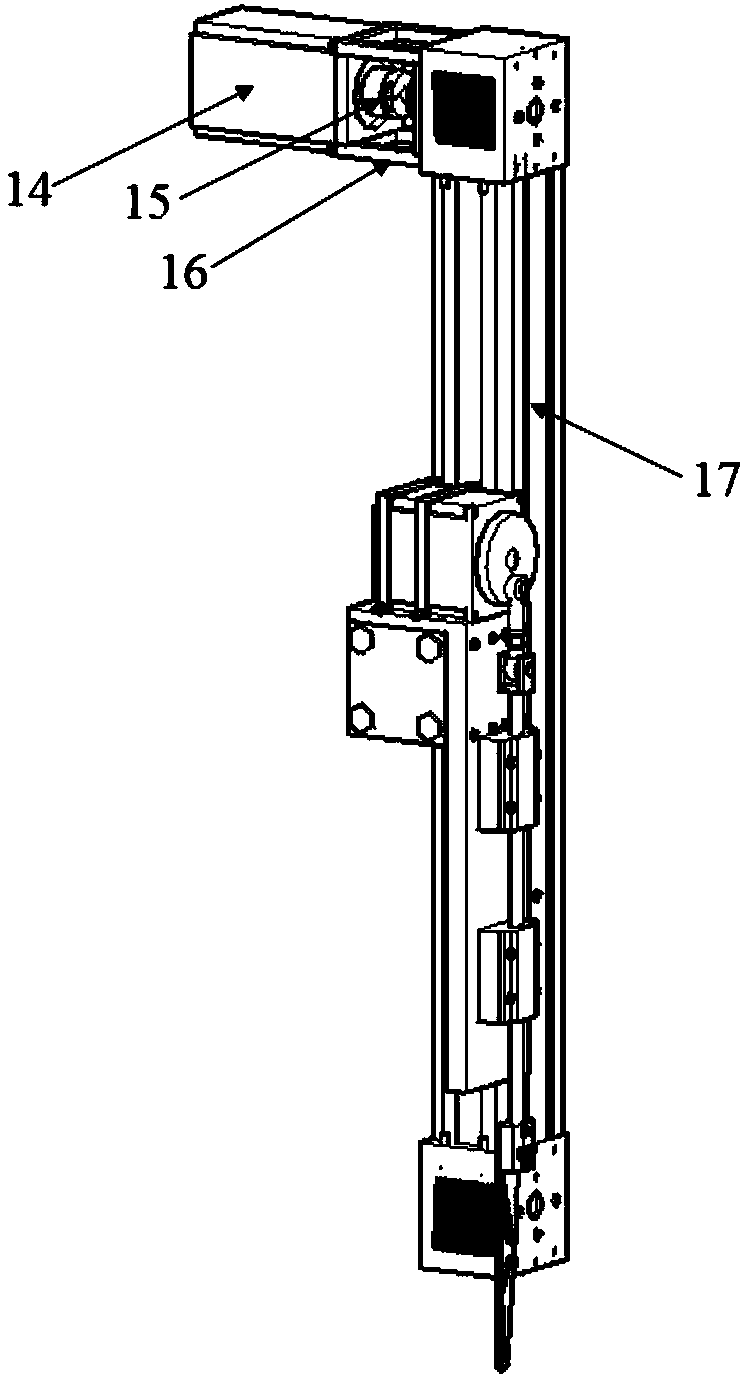

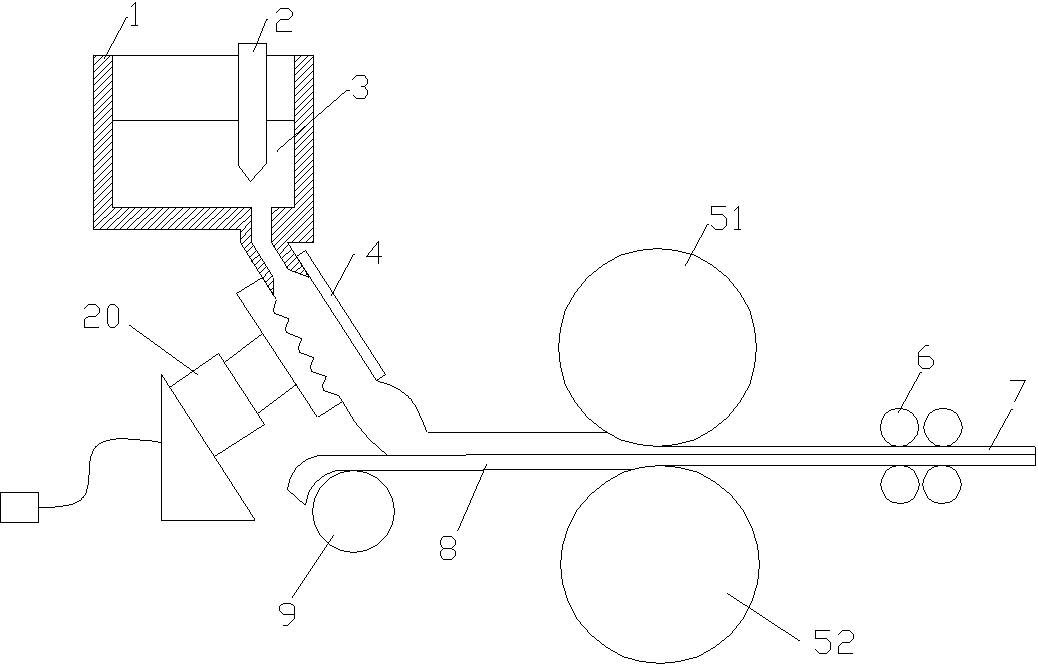

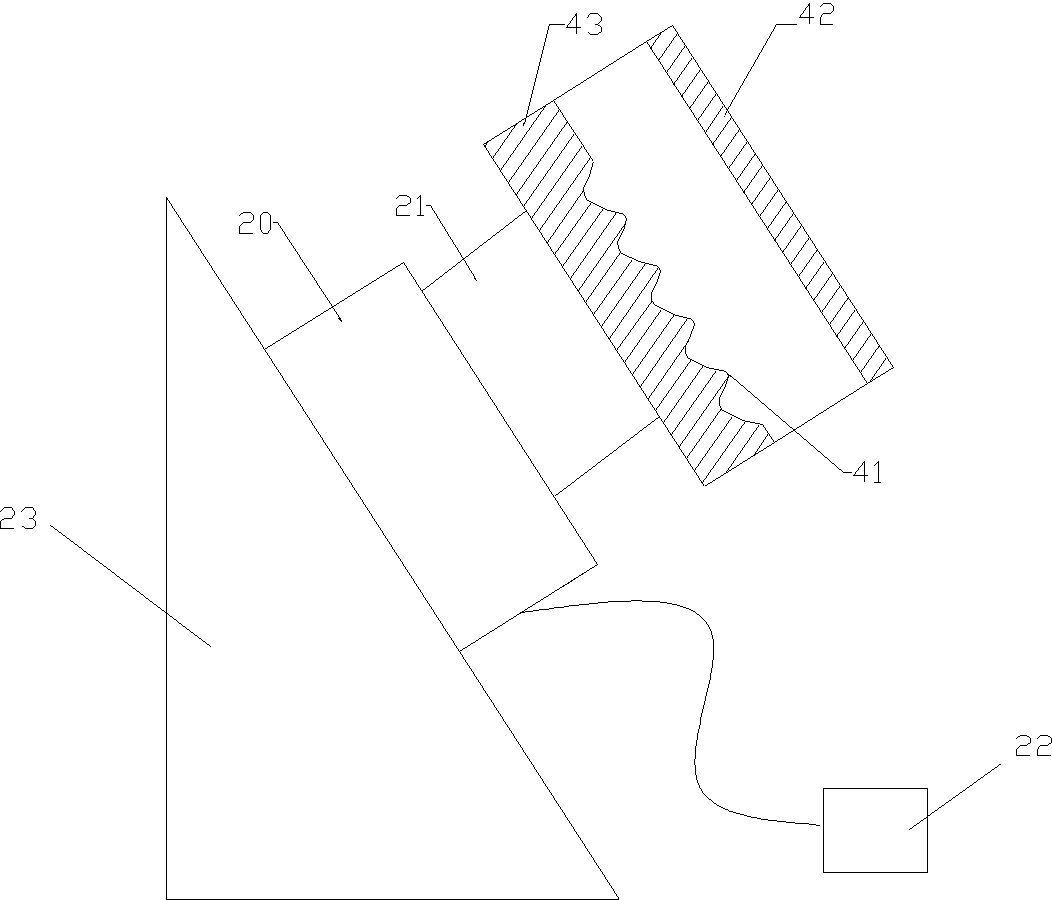

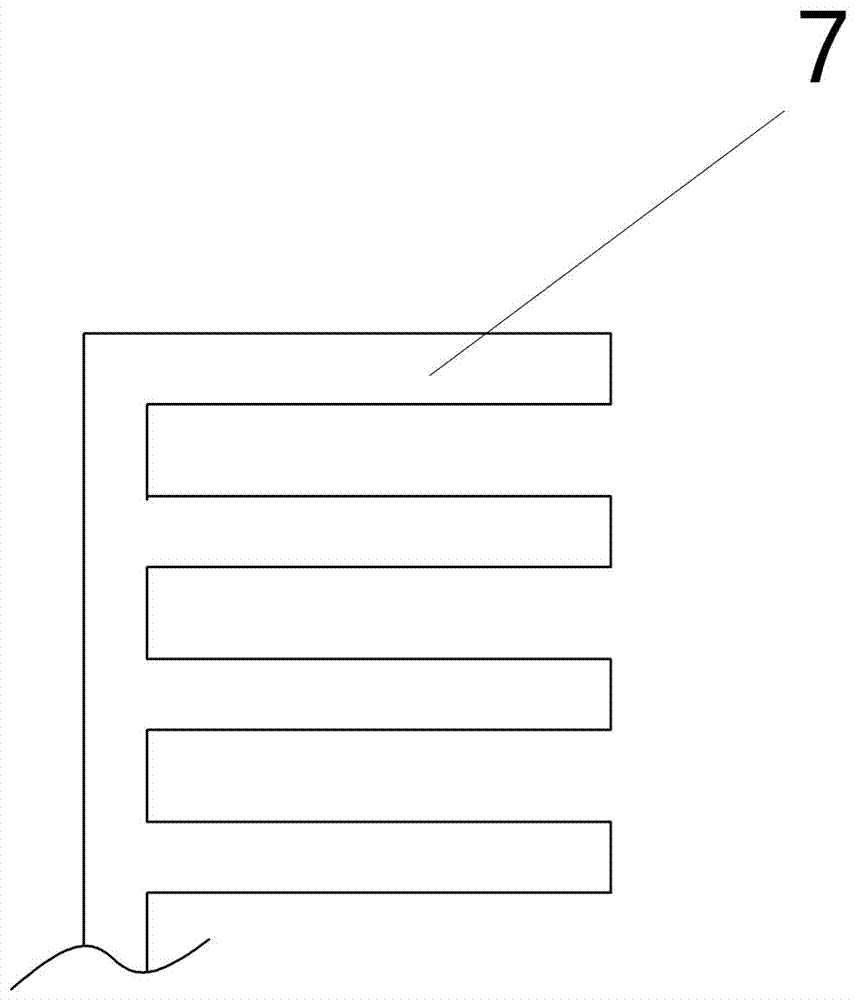

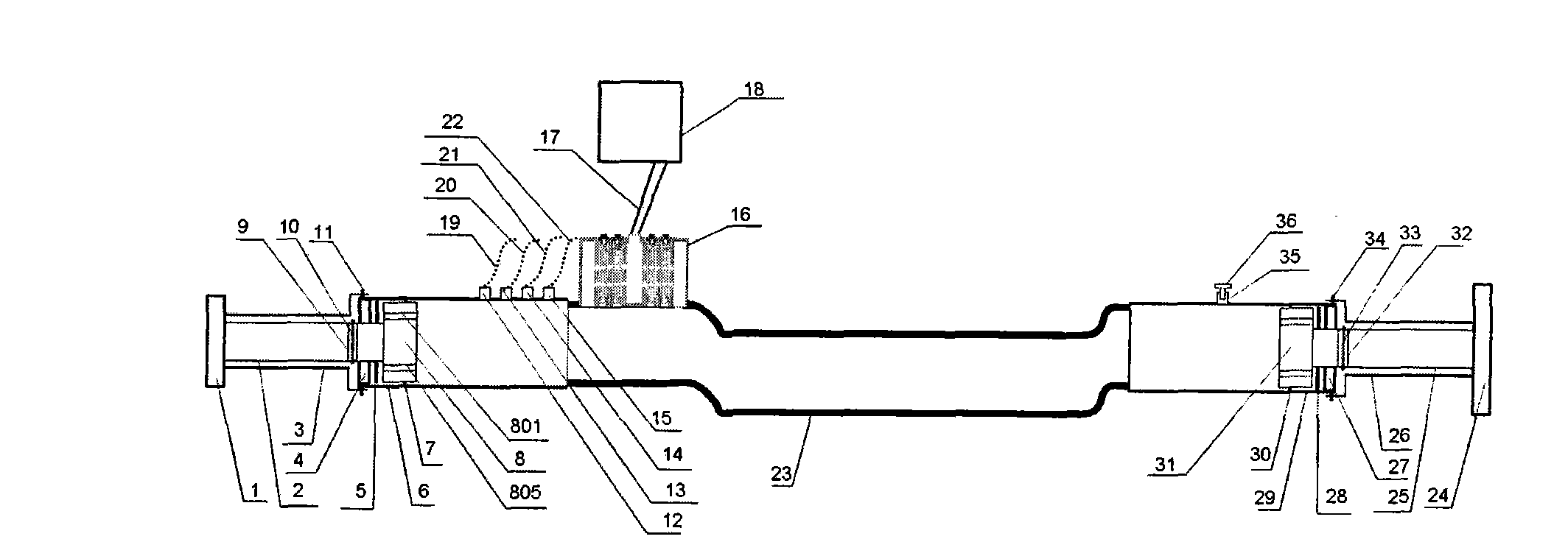

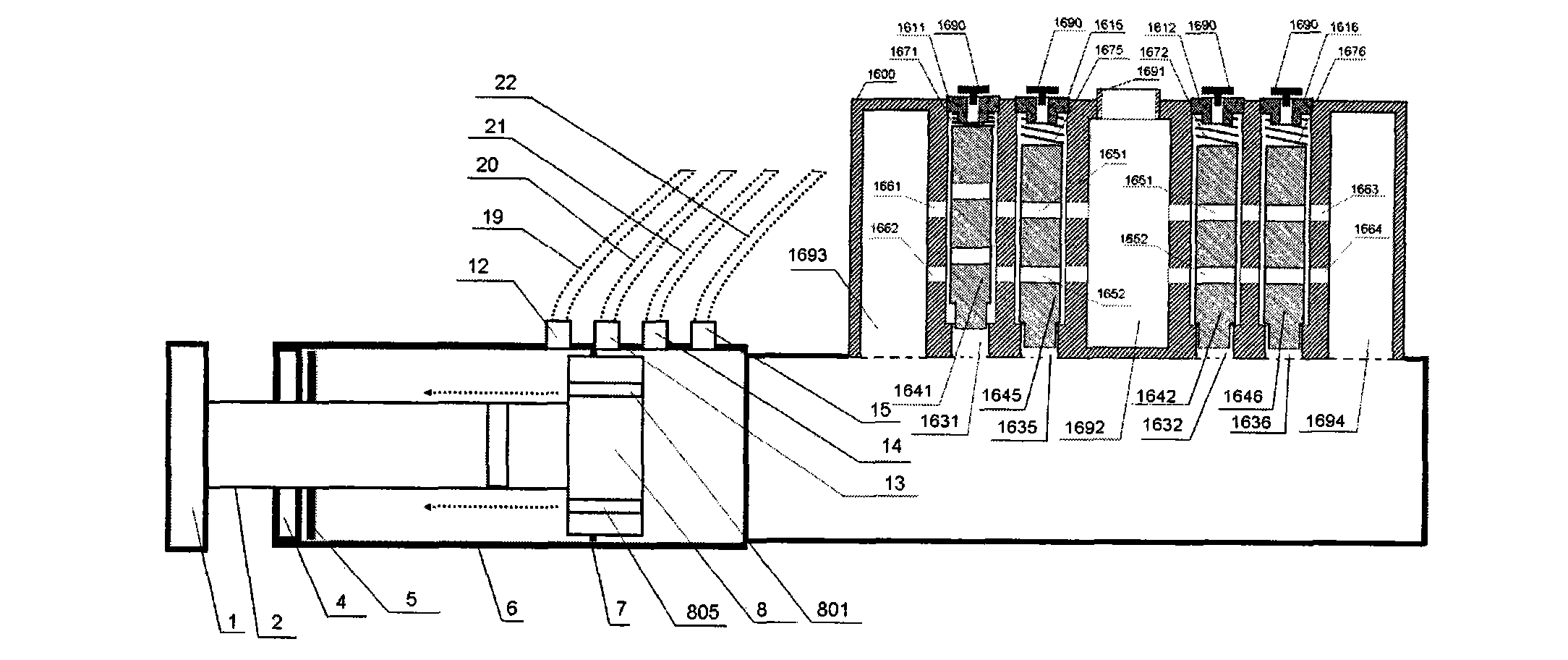

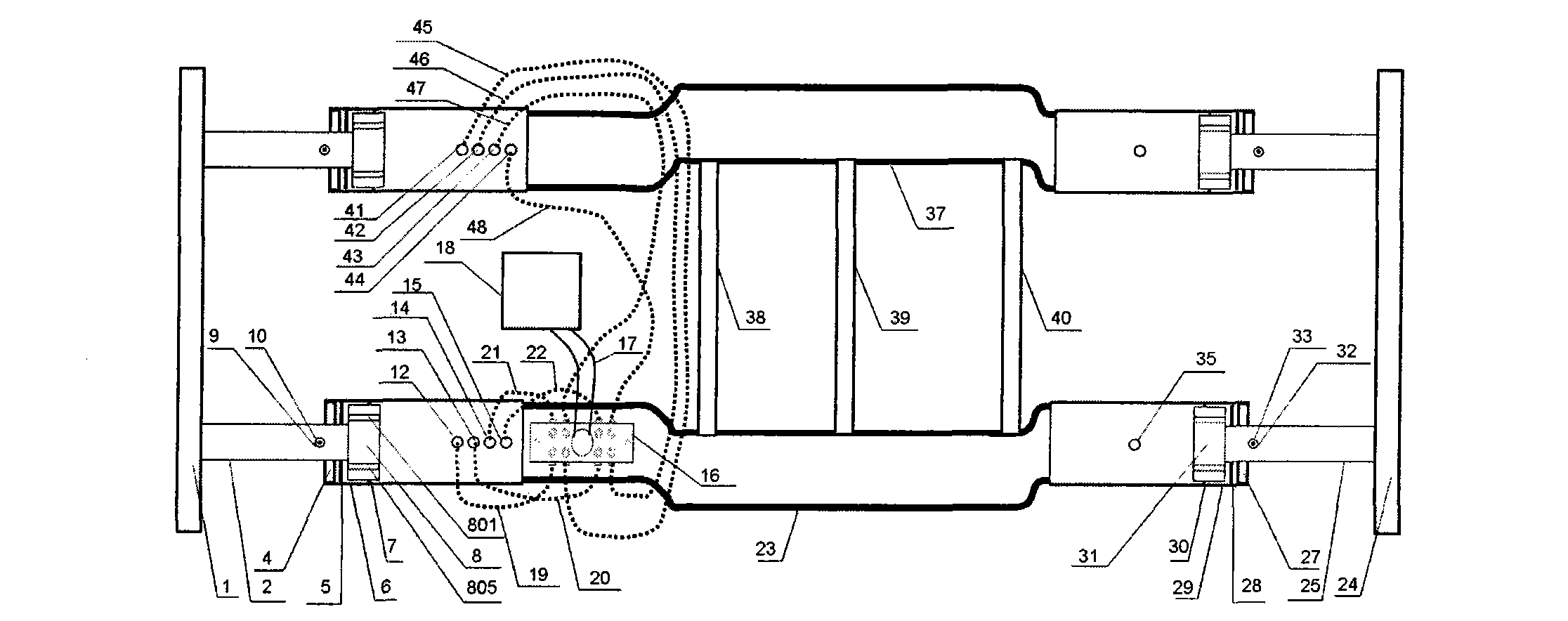

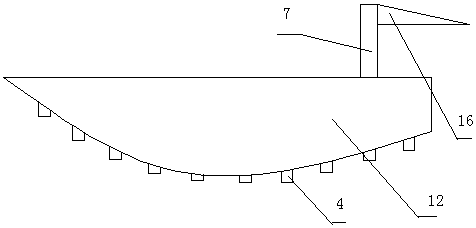

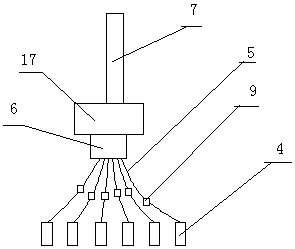

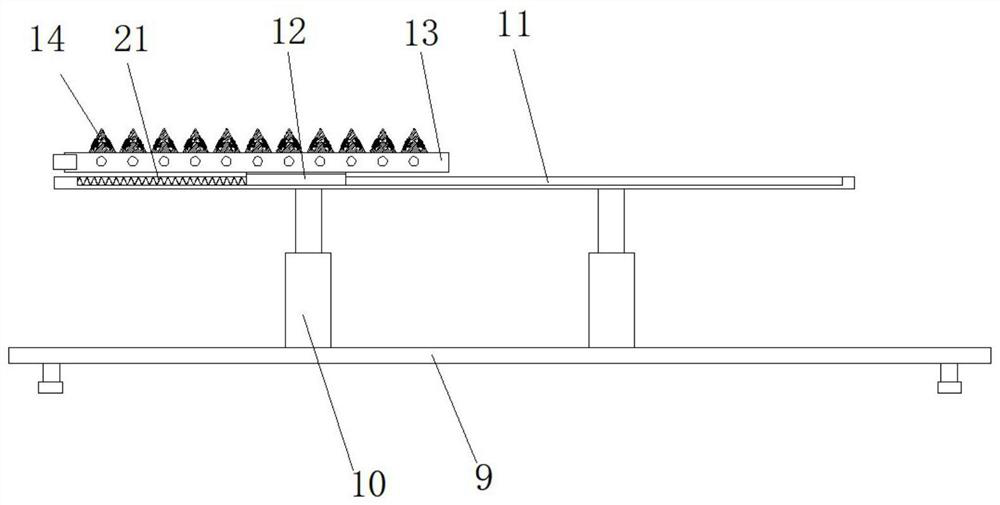

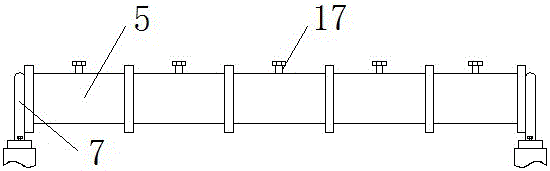

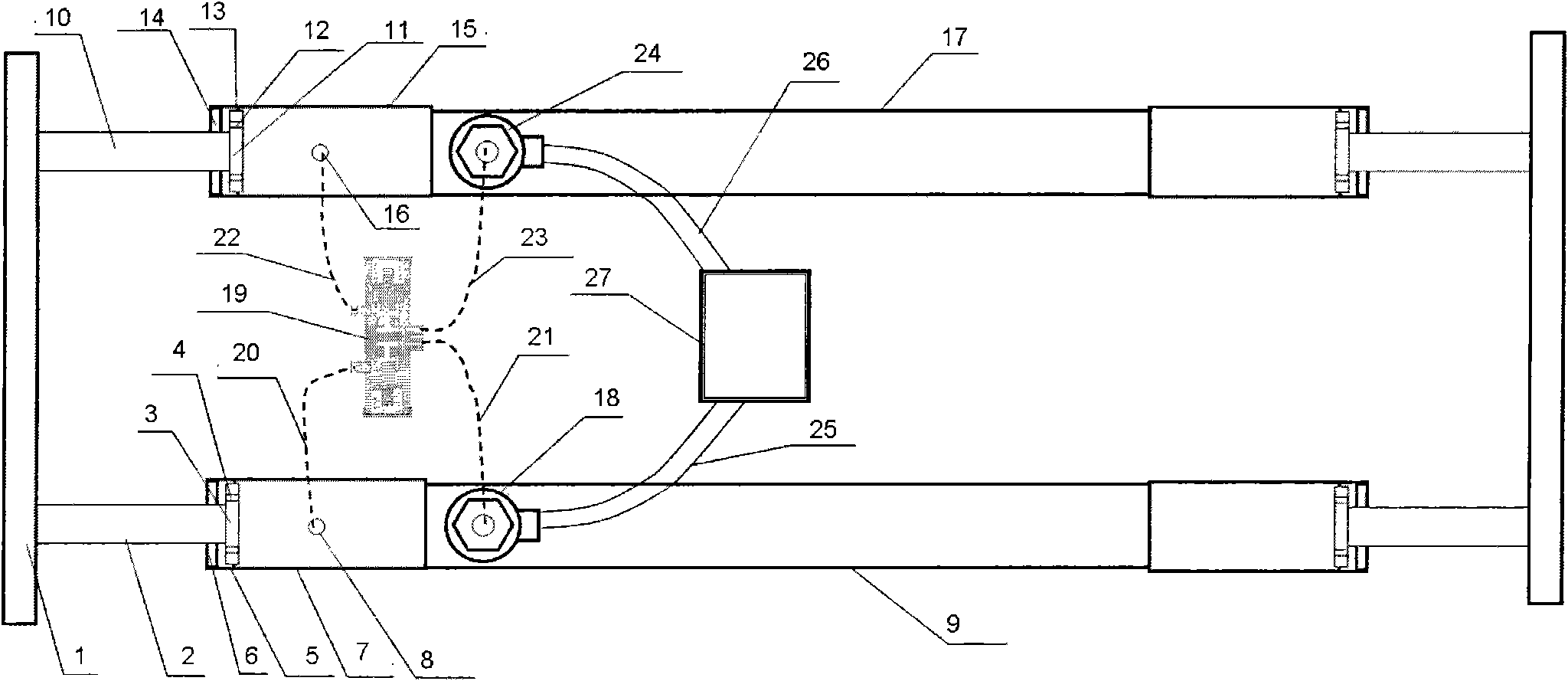

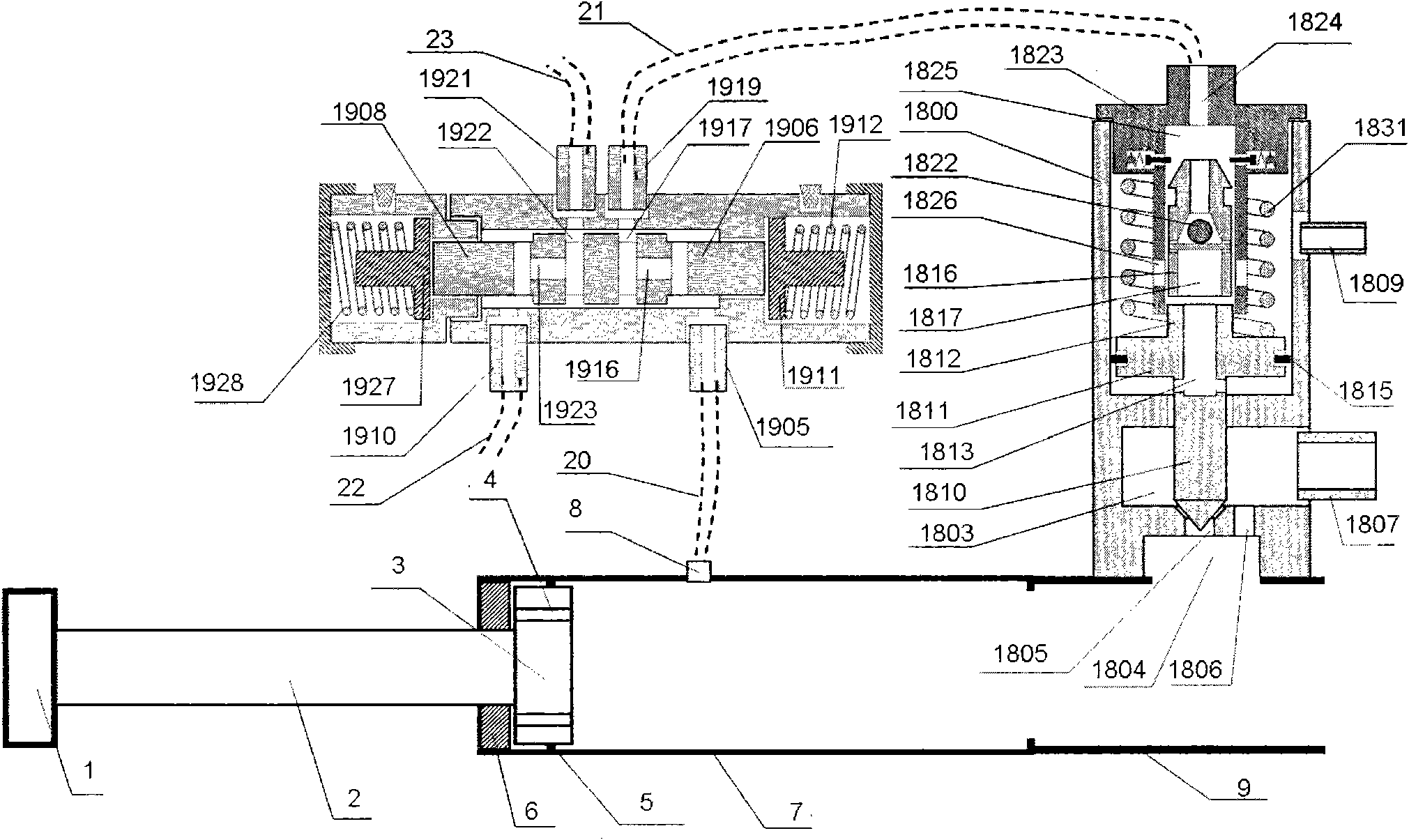

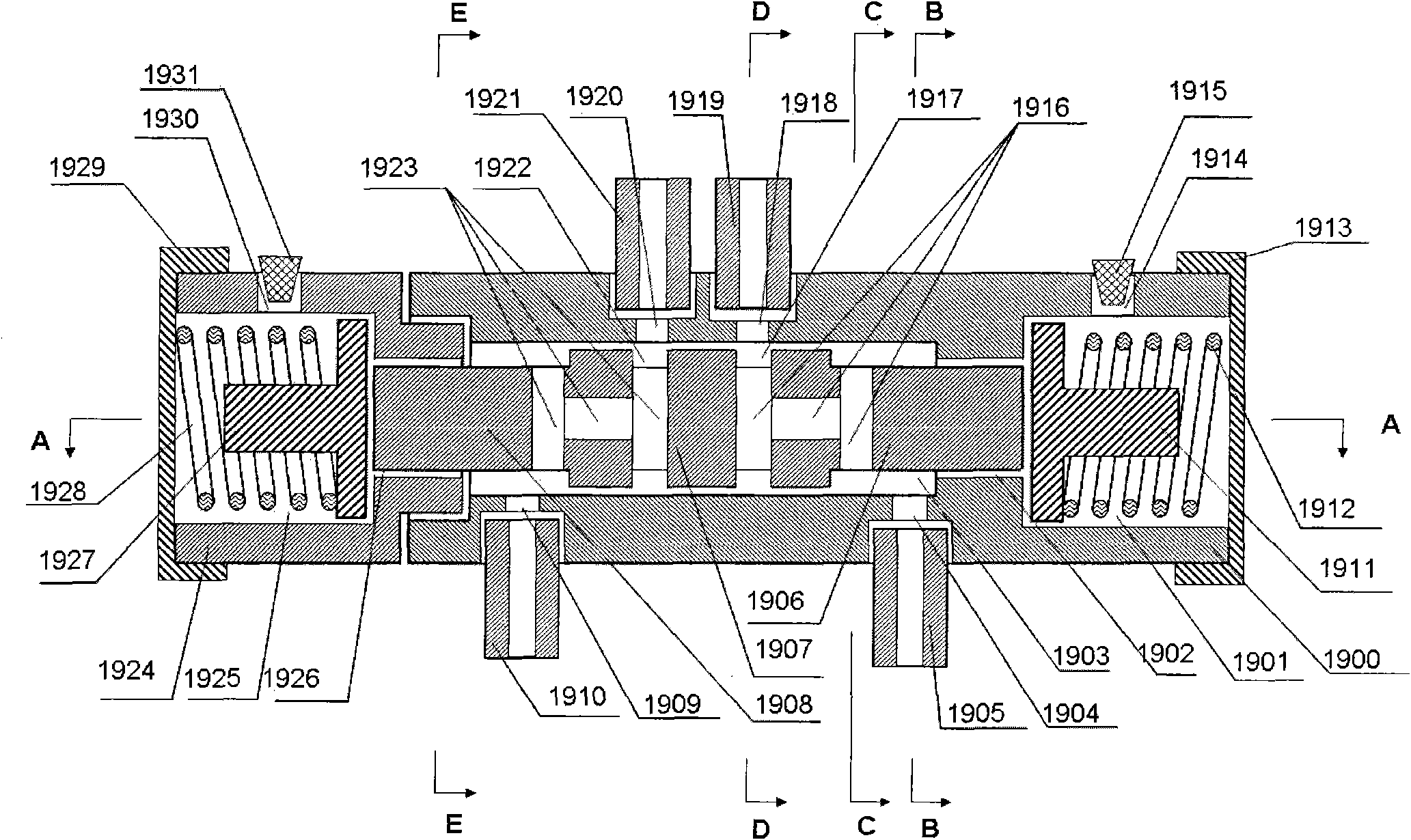

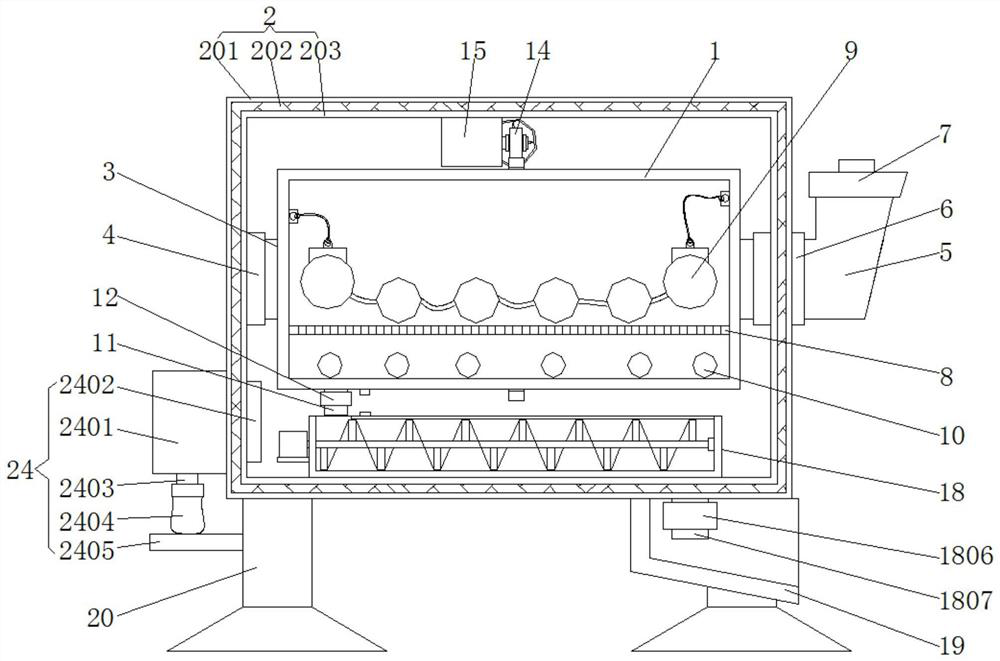

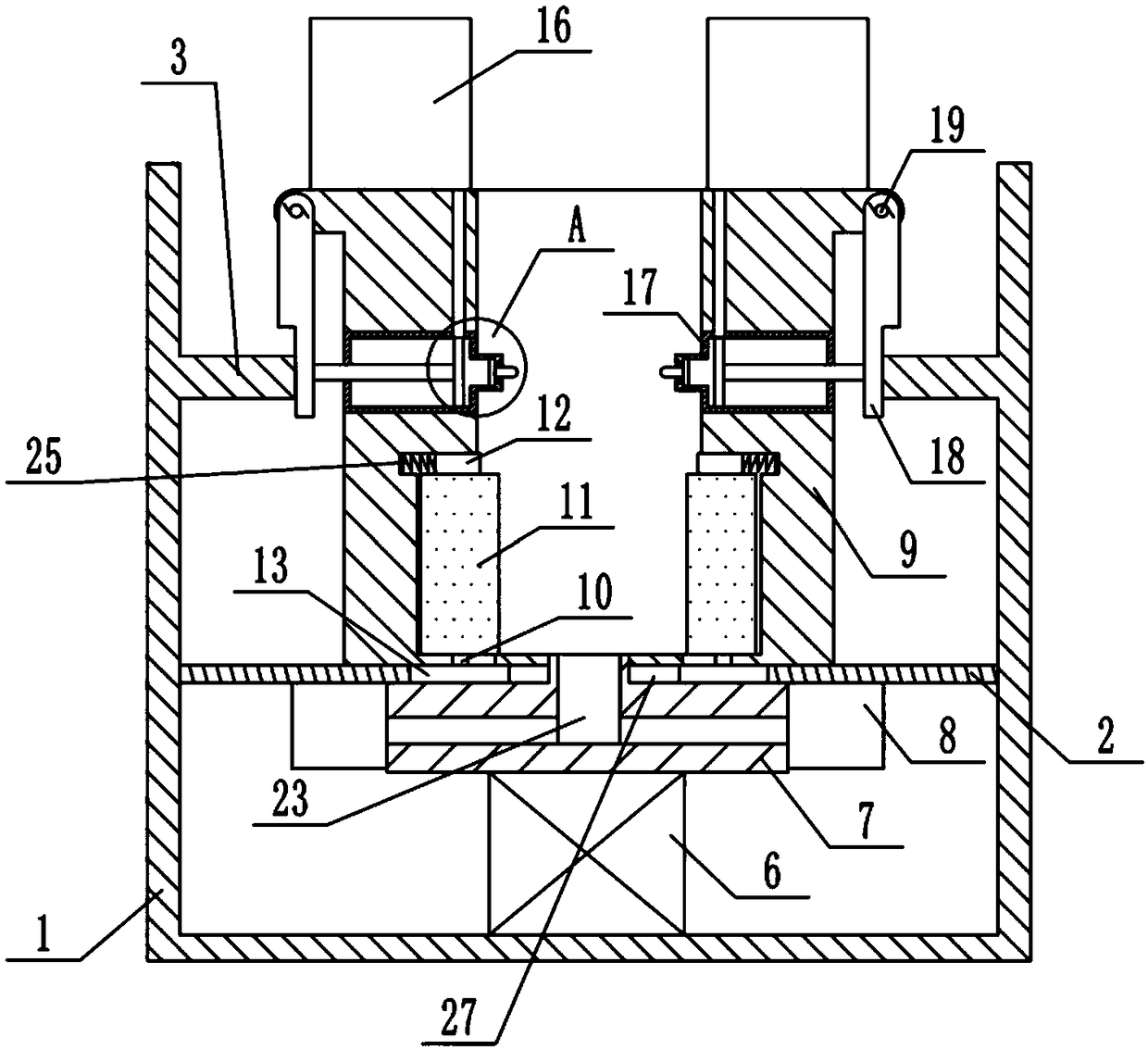

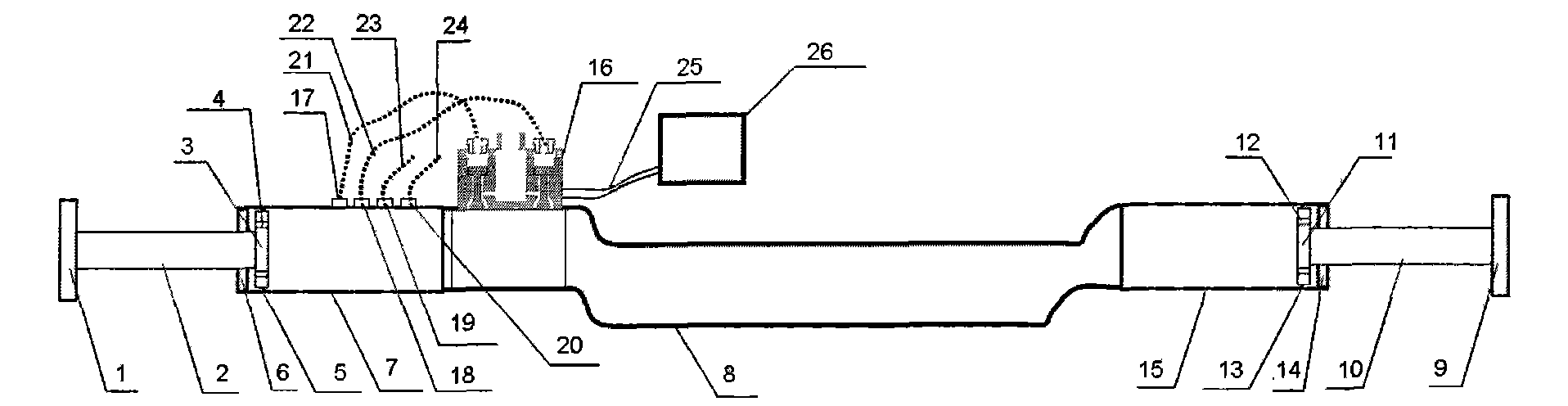

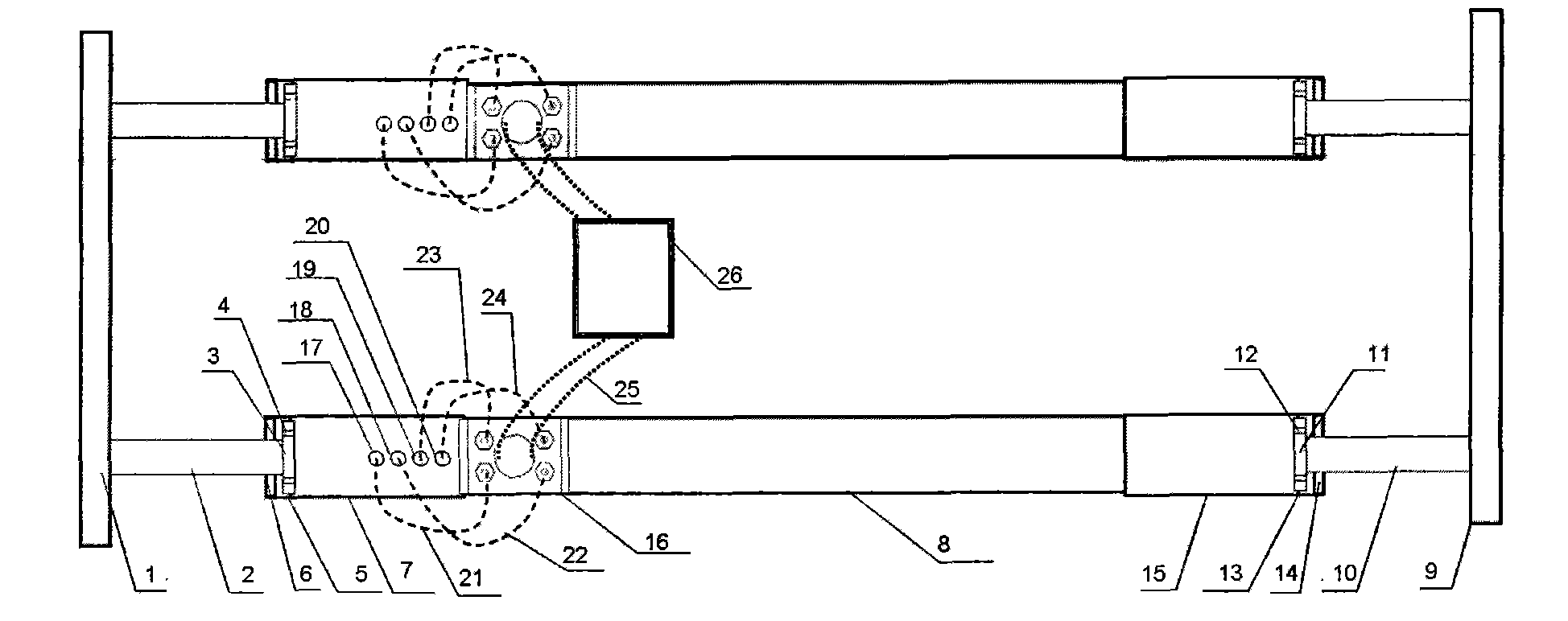

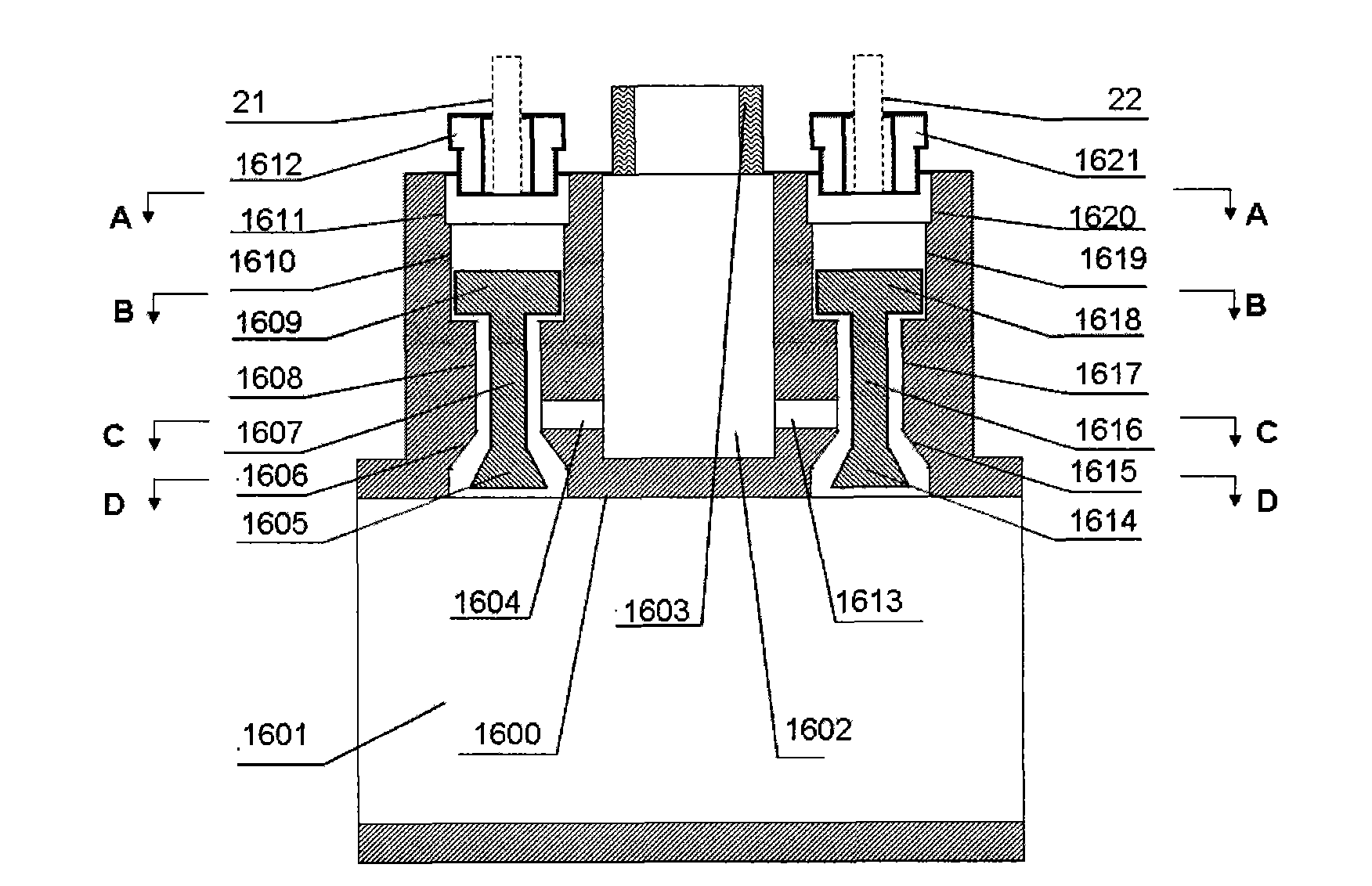

Ice pool trash ice navigation channel generation device

ActiveCN108444673ARealize moving up and downEasy to installHydrodynamic testingMarine engineeringChannel width

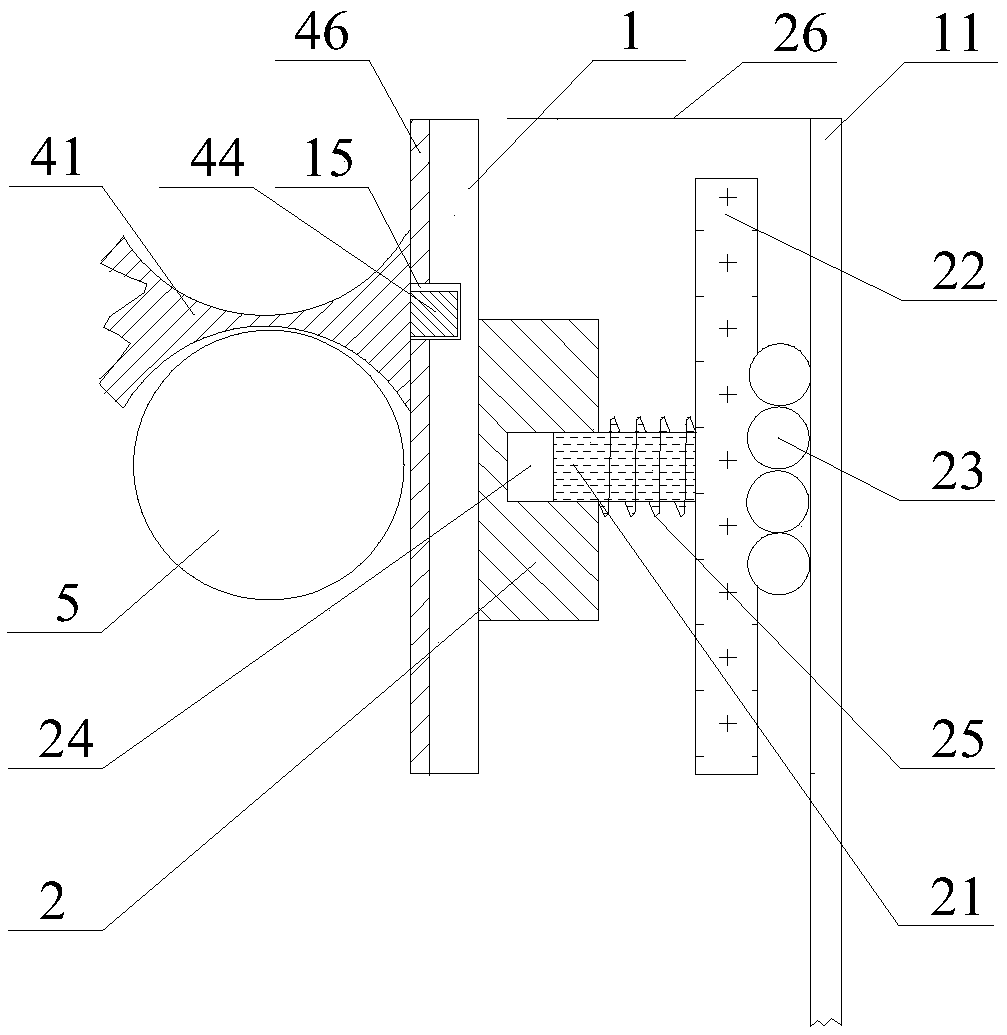

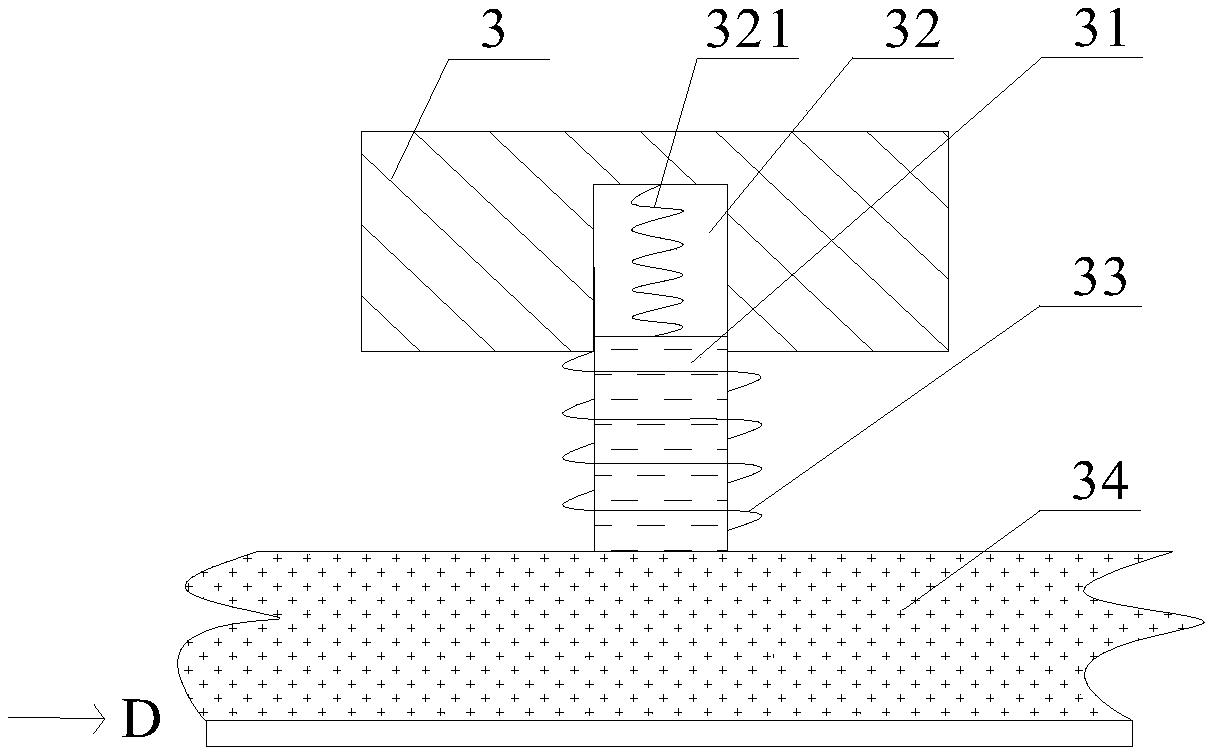

The invention provides an ice pool trash ice navigation channel generation device, including a sliding device, an ice cutting connecting device, and a collision device. The sliding device is mainly fixed on a service trailer, and can satisfy that the ice cutting connecting device cuts ice on different width directions of the ice pool, and the sliding device is connected with the ice cutting connecting device through a flange sliding block. The ice cutting connecting device is mainly used to cut flat ice, to separate a trash ice navigation channel. Large-scale ice blocks after cutting need to be collided into trash ice by the collision device, so as to satisfy requirement of ice pool trash ice experiments. The device is suitable to be used to generate a trash ice navigation channel in an ice pool, and is advantaged by convenient operation, fast trash ice generation speed, and easy adjustment of trash ice navigation channel widths and trash ice sizes, and greatly improves trash ice experiments in an ice pool laboratory, and reduces experiment cost of an ice pool.

Owner:HARBIN ENG UNIV

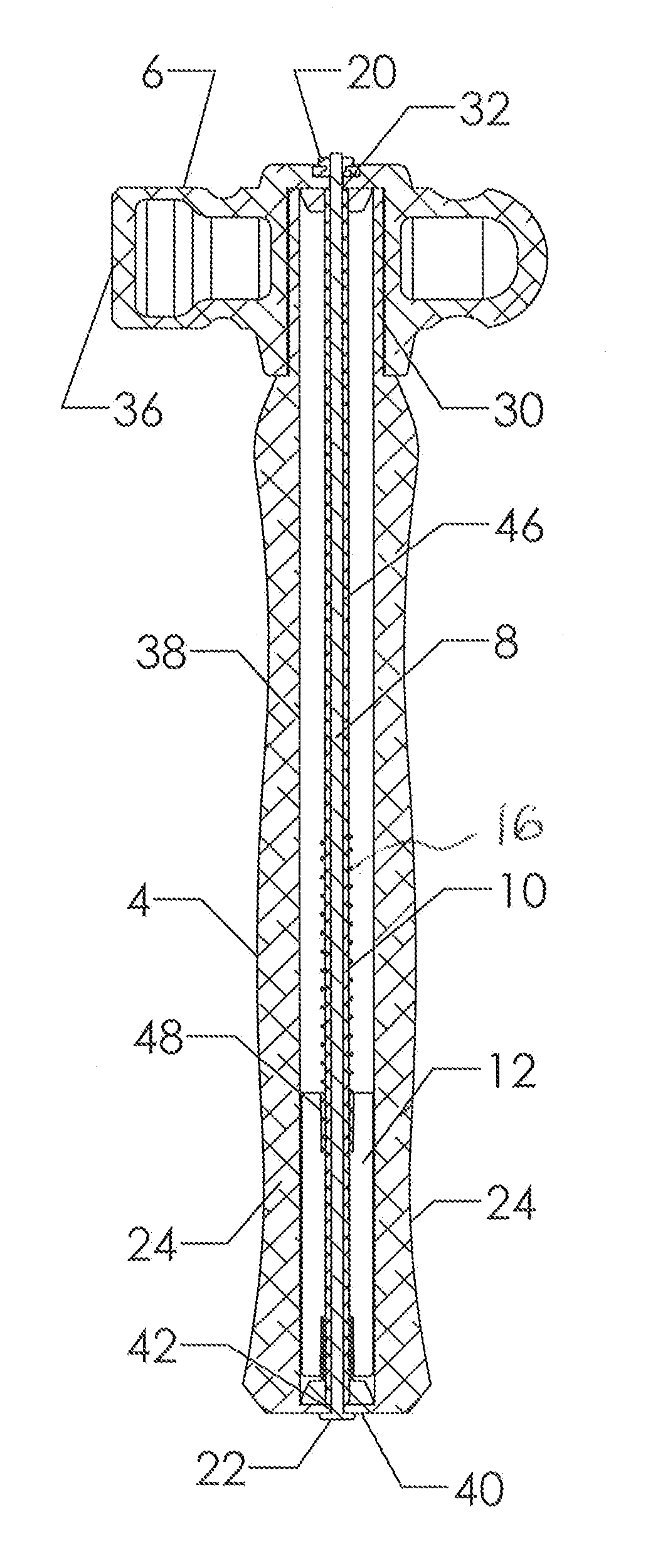

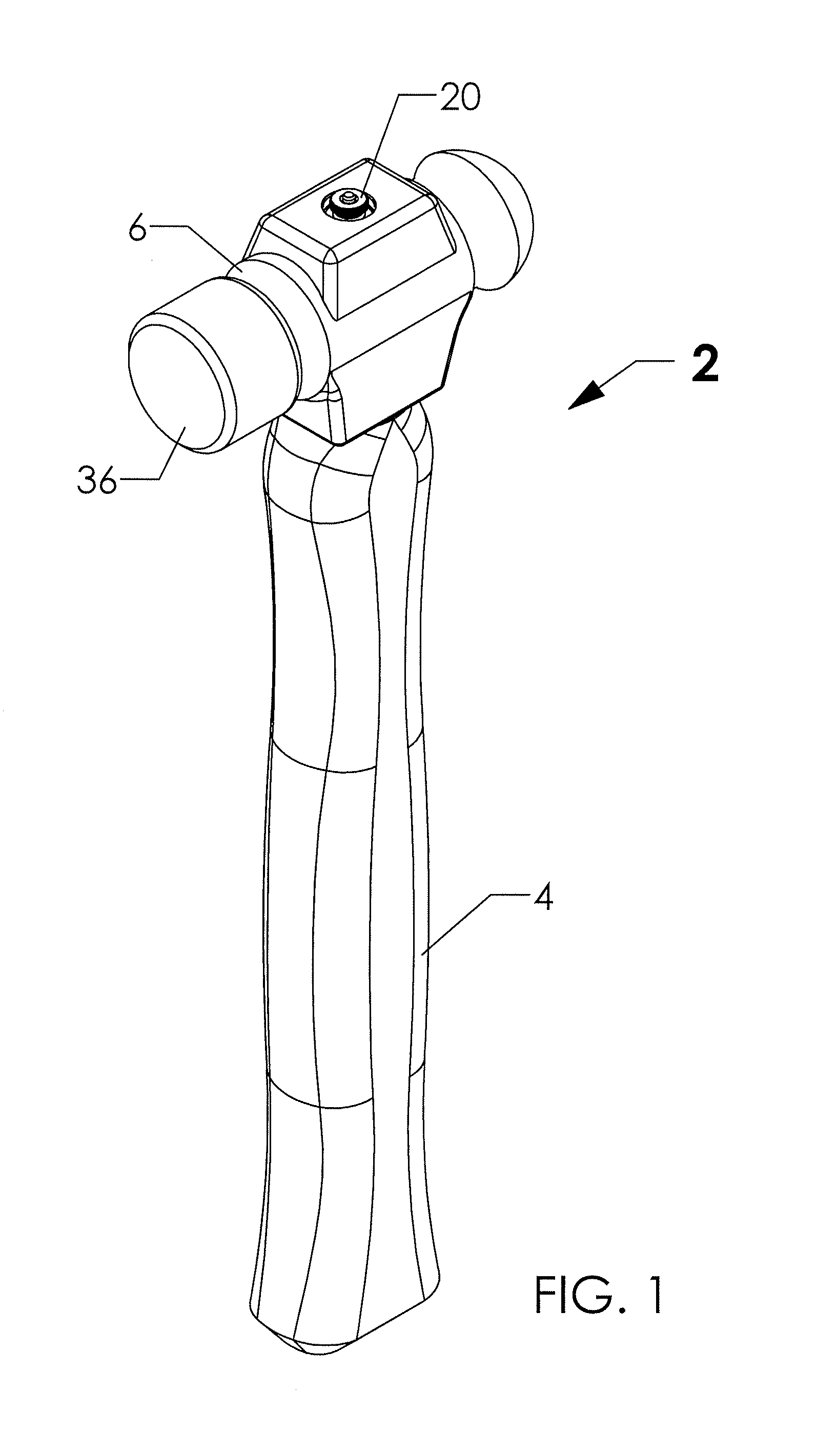

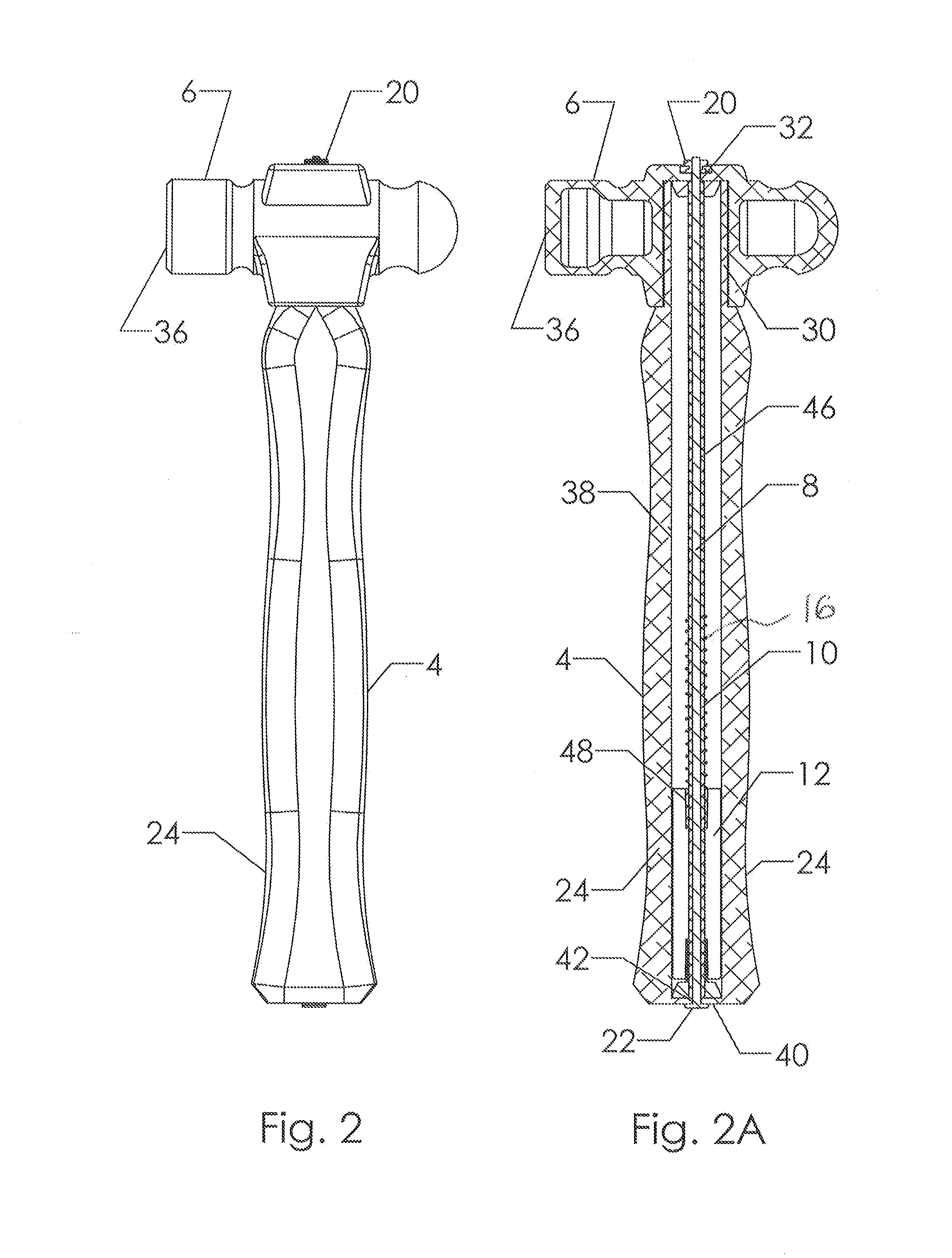

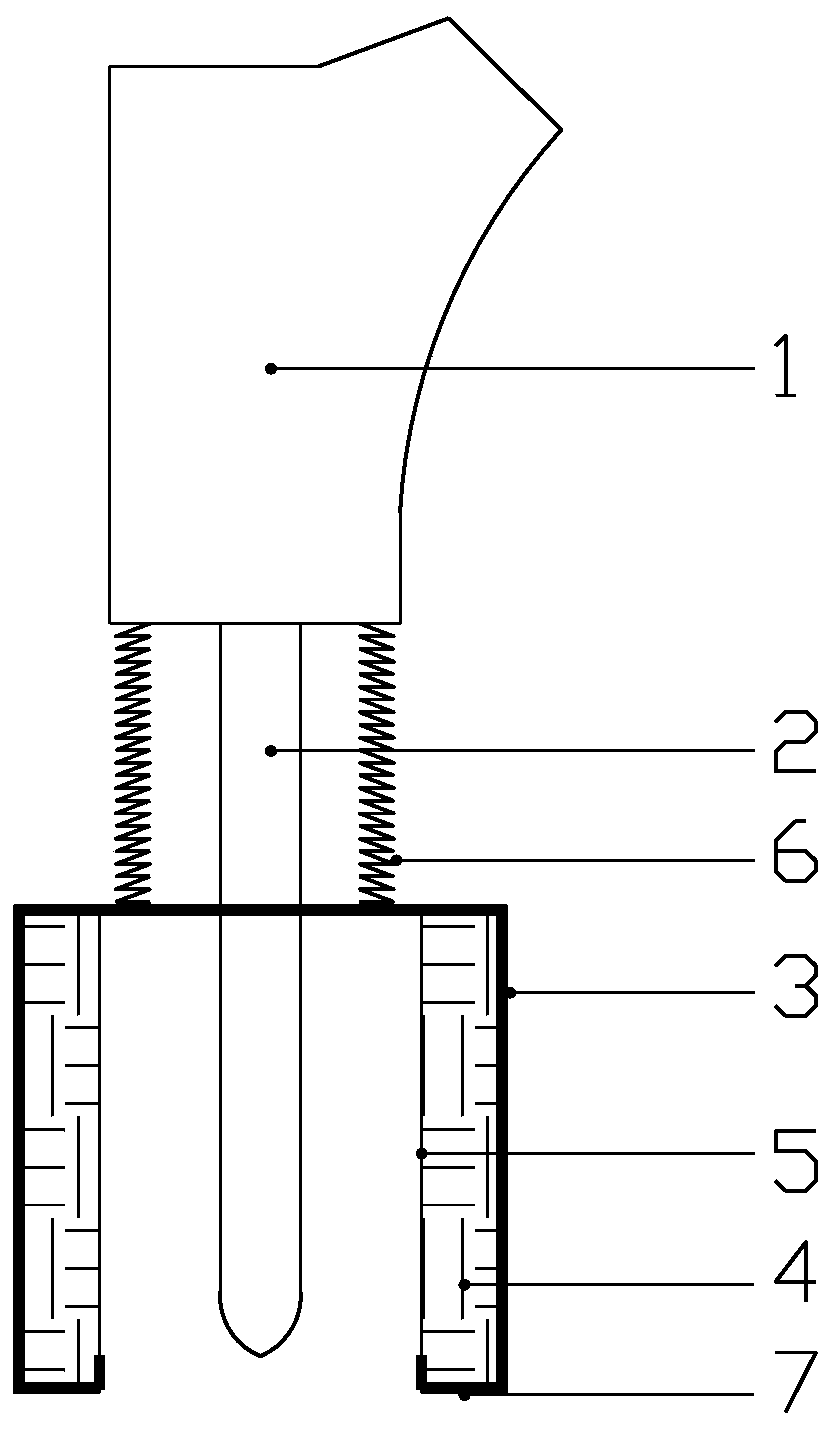

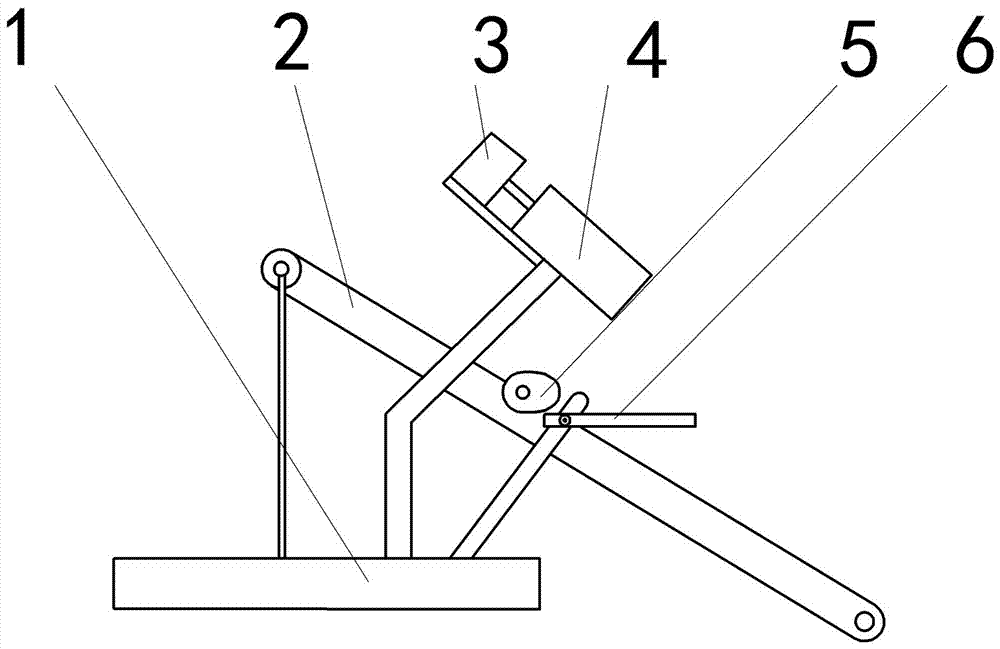

Striking device with sliding weight for increasing impact force

InactiveUS20140216210A1Angular velocity stabilityEasy to usePortable percussive toolsHand hammersEngineering

A striking device comprising a striking head, an elongate handle comprising a first end and an opposed second end. The striking head is affixed to the first end while the second end has a hand grip which facilitates gripping of the handle by an operator of the striking device. The handle accommodates a sliding weight which is movable, due to a swinging motion of the striking device, from the first end of the handle toward the second end of the handle to increase an impact force of the striking head as the striking head strikes an object to be struck.

Owner:NEAR TIMOTHY J

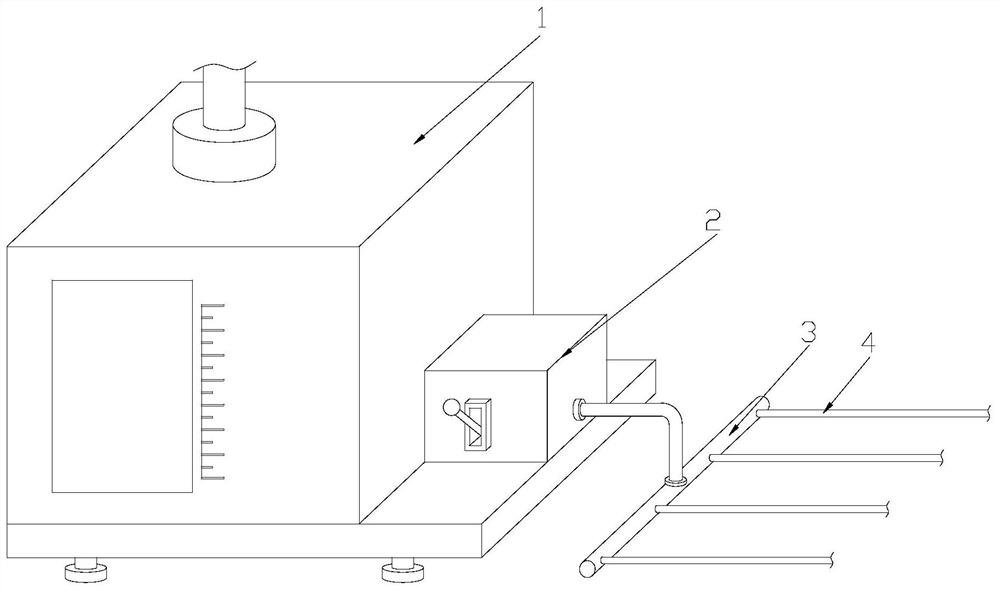

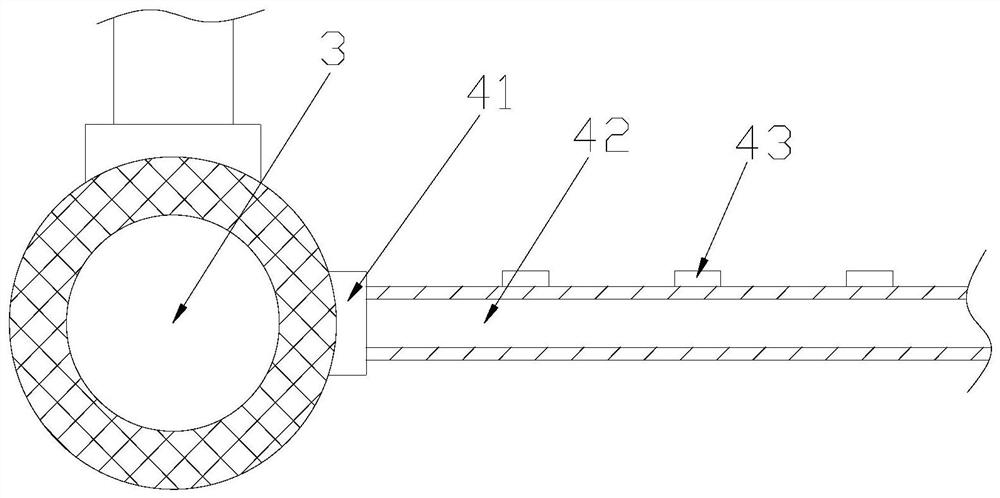

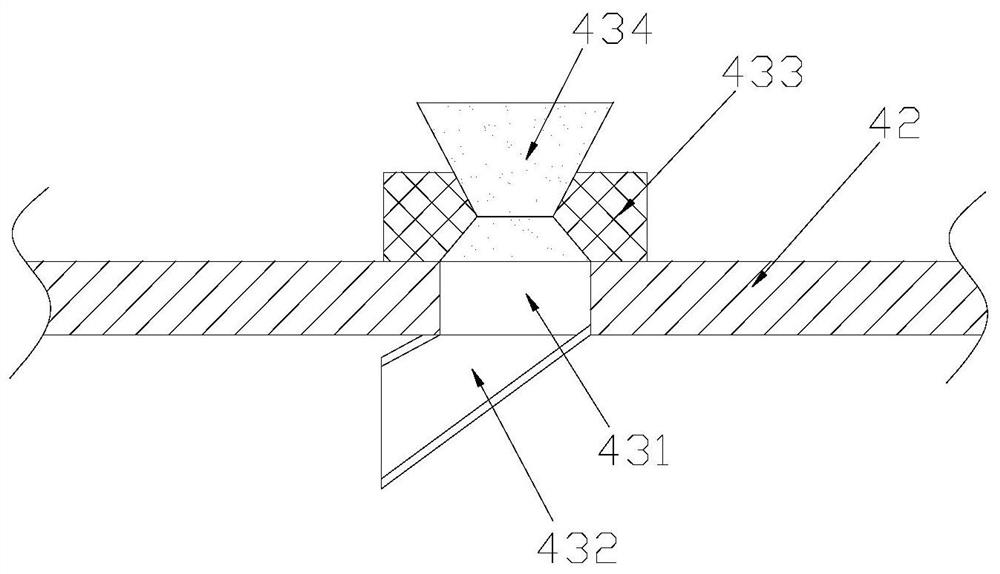

Semi-solid slurrying device and composite board manufacturing device using semi-solid slurrying device

The invention relates to the technical field of semi-solid slurrying, in particular to a semi-solid slurrying device and a composite board manufacturing device using the semi-solid slurrying device. The semi-solid slurrying device comprises a runner communicated with a liquid storage tank, obliquely arranged from top to bottom and used for molten metal to flow through, wherein the runner is provided with the contact surface in contact with the molten metal, strip-shaped protrusions parallelly distributed from top to bottom are arranged on the contact surface, grooves are formed among adjacent strip-shaped protrusions, the length directions of the strip-shaped protrusions are perpendicular to the flowing direction of the molten metal. By adopting the semi-solid slurrying device, the kish problem of the contact surface of the runner is greatly solved, high-quality semi-solid slurry produced by the semi-solid slurrying device can form metallurgical bonding with a solid heterogeneous material, and further the technical problem that interface metallurgical bonding is difficult to achieve by adopting a traditional composite board manufacturing process is further effectively overcome.

Owner:HENAN UNIV OF SCI & TECH

Excavator breaking hammer protection device and using method thereof

ActiveCN109695267AProtect from injuryReasonable structural designMechanical machines/dredgersEngineeringExcavator

The invention relates to an excavator breaking hammer protection device and a using method thereof. The excavator breaking hammer protection device comprises a breaking hammer, a buffer piece and a protection piece; the breaking hammer comprises a machine arm and an impact rod mounted below the machine arm; the protection piece comprises a rubber barrel with an opening in the bottom, a mounting hole allowing the impact rod to penetrate is formed in the top of the rubber barrel, the rubber barrel and the impact rod are fixedly connected into a whole, and the bottom end of the impact rod is lower than the bottom of a barrel body of the rubber barrel; rock wool wetted in a watered mode is fixedly arranged on the inner wall of the rubber barrel; a galvanized welded wire mesh is arranged outside the rock wool in a covering mode and used for fixing the galvanized welded wire mesh to the inner wall of the rubber barrel; and the buffer piece is arranged between the machine arm and the top of the rubber barrel. The excavator breaking hammer protection device has the advantages of reasonable structure design, convenient mounting and demounting, low maintenance cost and relatively-high automation degree, and the problem that the surrounding building population and the like are harmed by noise pollution and environmental pollution in the construction operation process can be effectively solved.

Owner:TAIYUAN FIRST BUILDING & ENG GRP

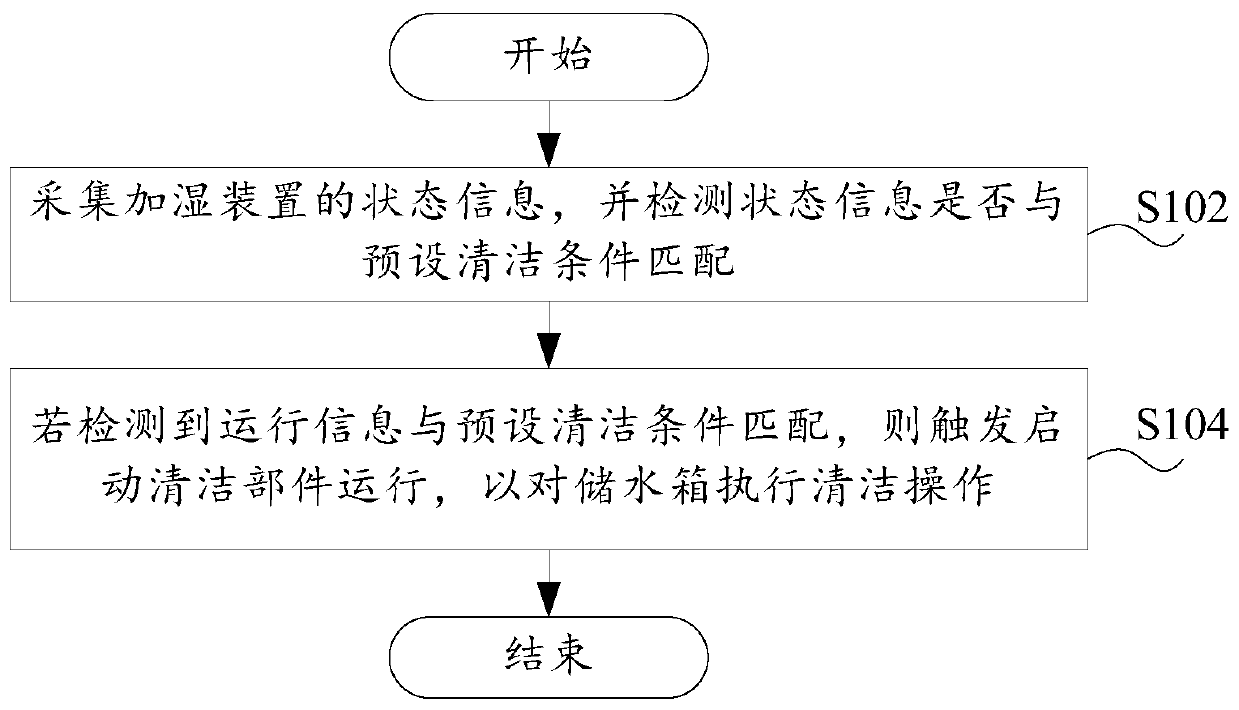

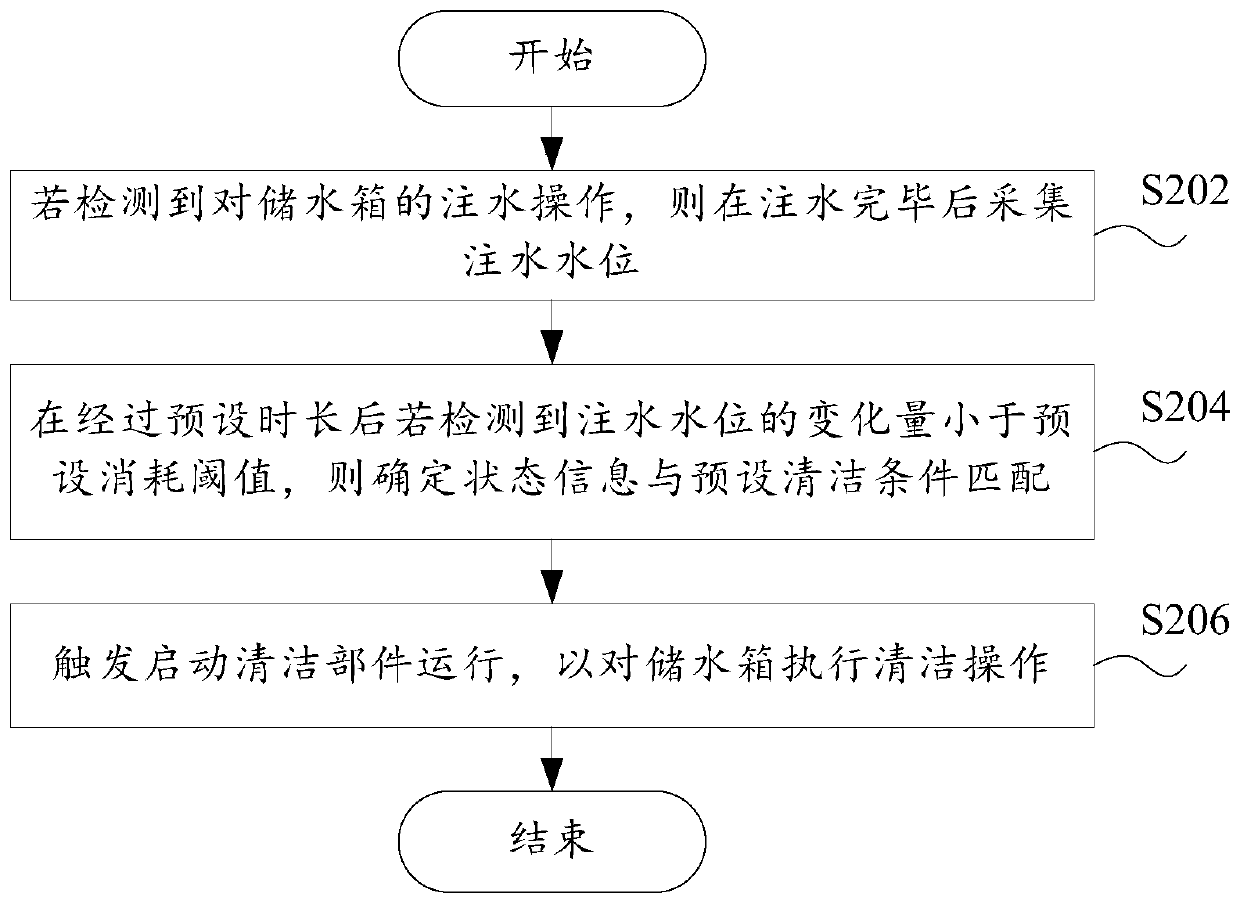

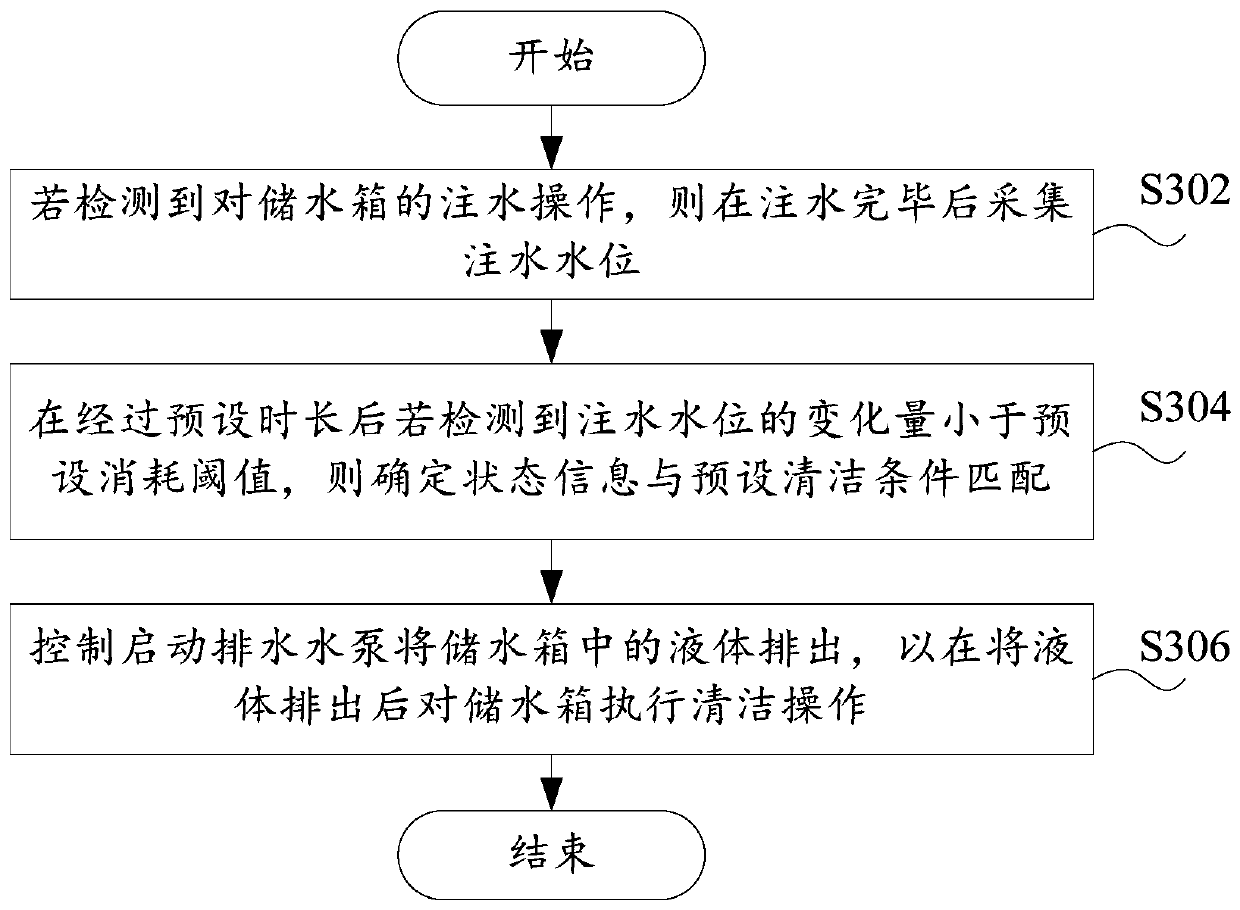

Self-cleaning control method, self-cleaning control device, air conditioner and storage medium

ActiveCN109974195ASatisfy cleanlinessFulfil requirementsMechanical apparatusSpace heating and ventilation safety systemsWater storageWater storage tank

The invention provides a self-cleaning control method, a self-cleaning control device, an air conditioner and a storage medium. The self-cleaning control method comprises the following steps: acquiring state information of a humidifying state, and detecting whether state information is matched with a preset cleaning condition or not; and if the detected state information is matched with the presetcleaning condition, triggering to start a cleaning part to operate, thereby performing cleaning operation on a water storage tank. The steps of the self-cleaning control method are reasonably set, sothat clean operation can be performed on the water storage tank to clear dirt and impurities inside the water storage box, and therefore, the self-cleaning purpose of the humidifying device is realized, cleanliness of the water storage box is favorably improved, clean and sanitary liquid storage requirements needed when an air conditioner performs a humidifying mode are met, and safety in a usingprocess of the user is favorably improved while the humidifying device is guaranteed to normally operate.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

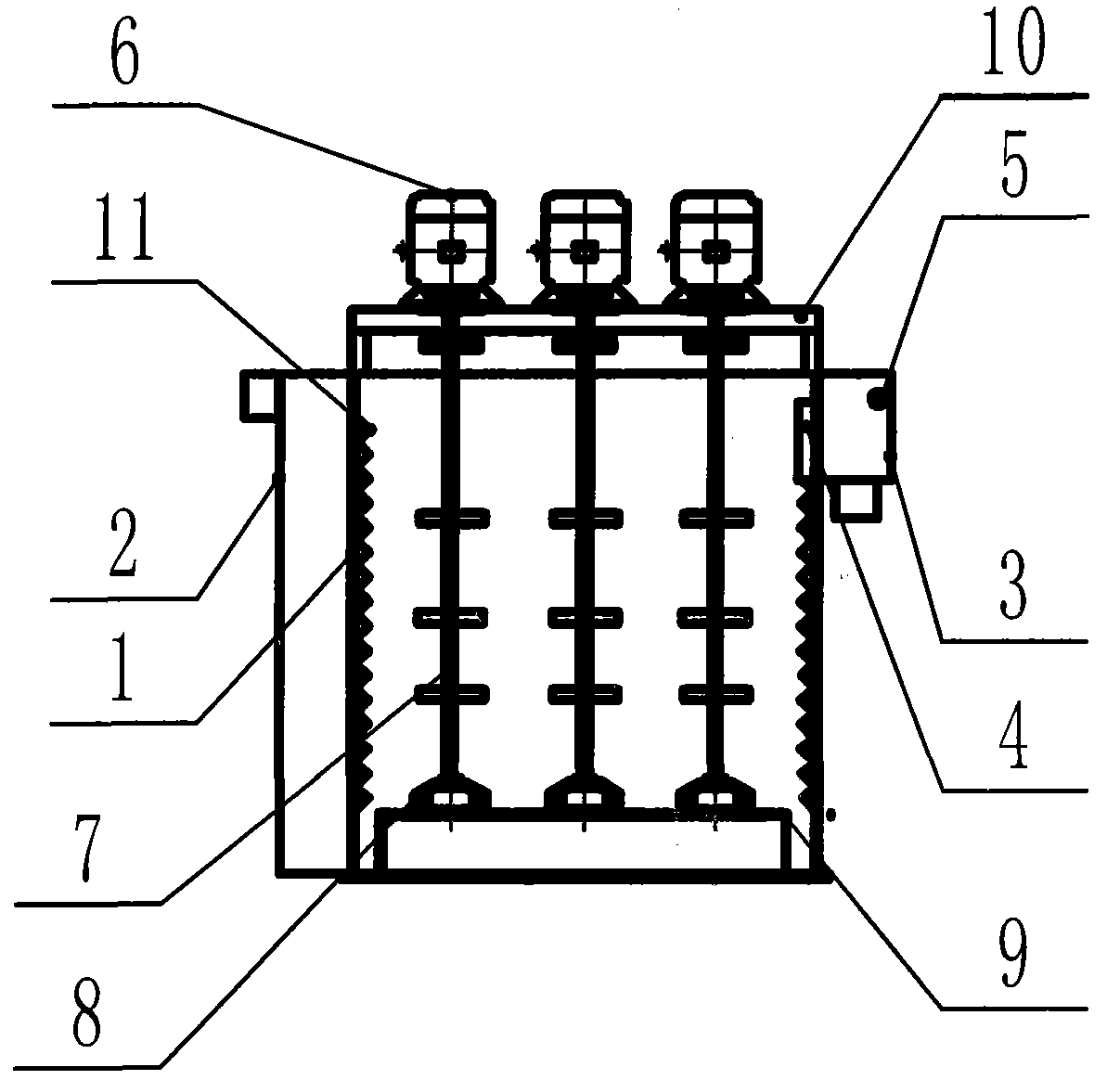

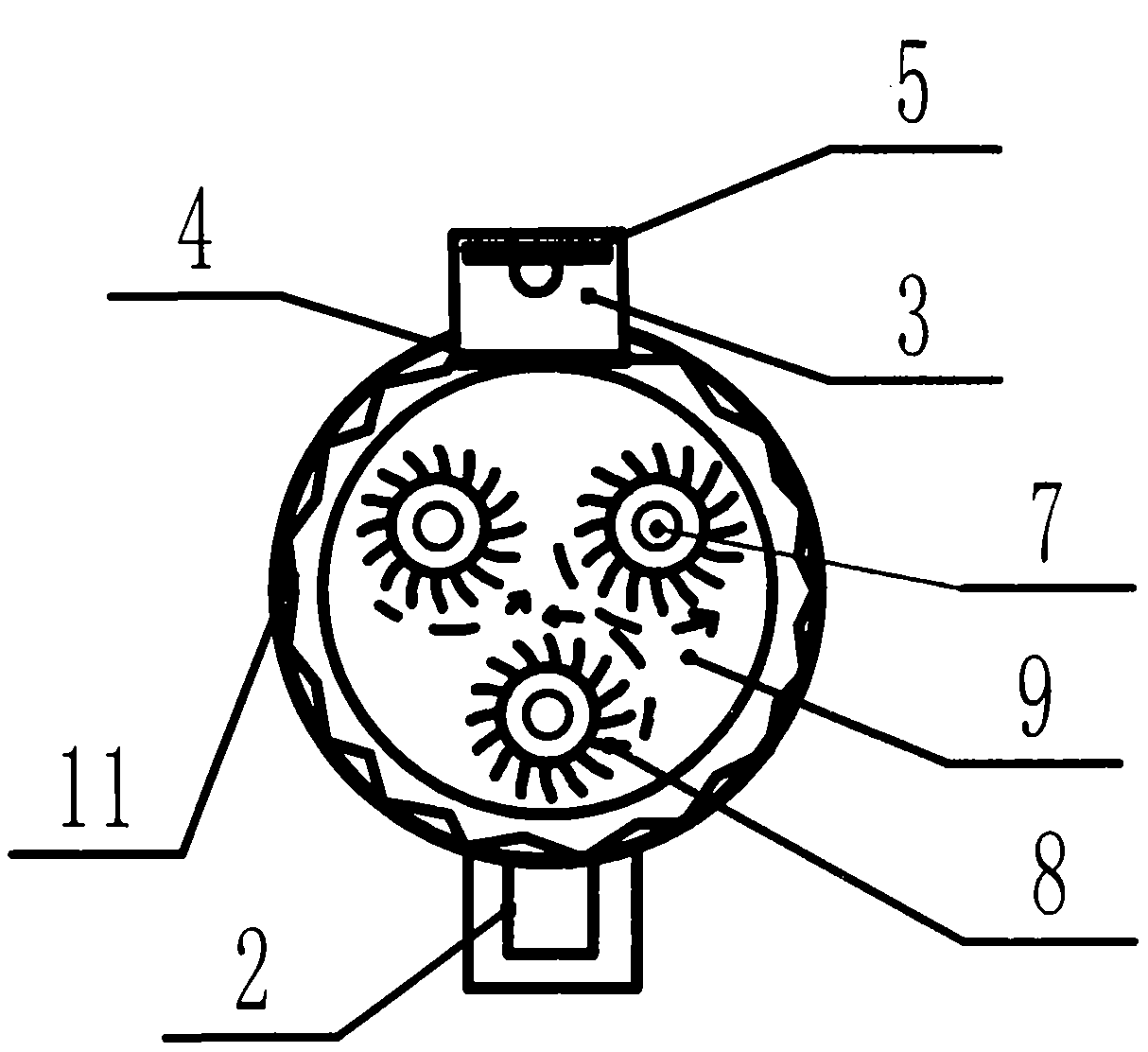

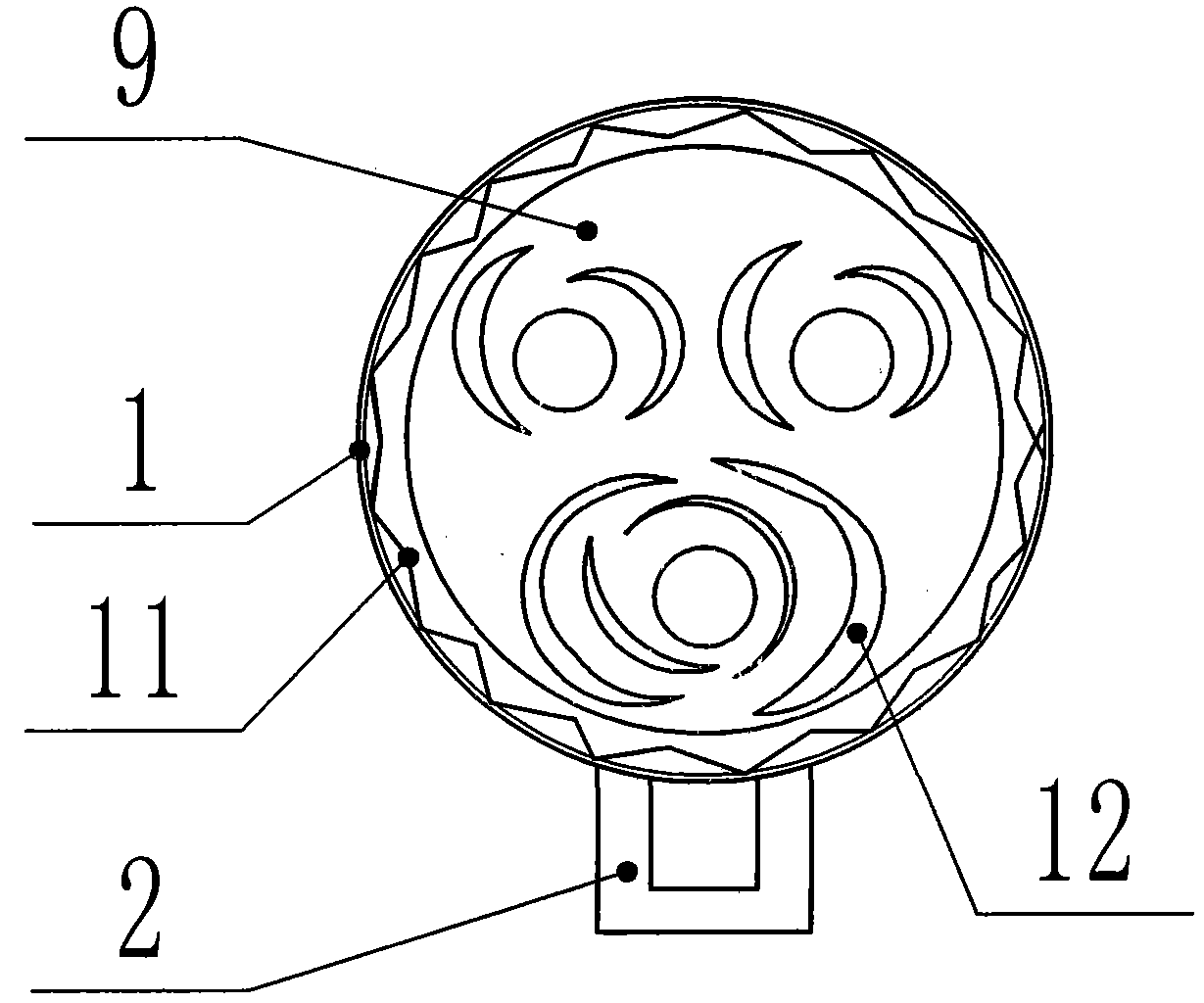

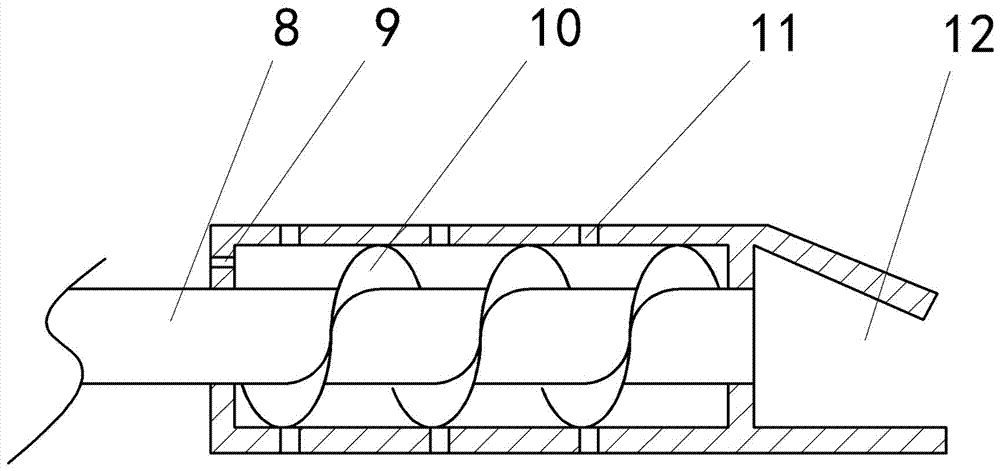

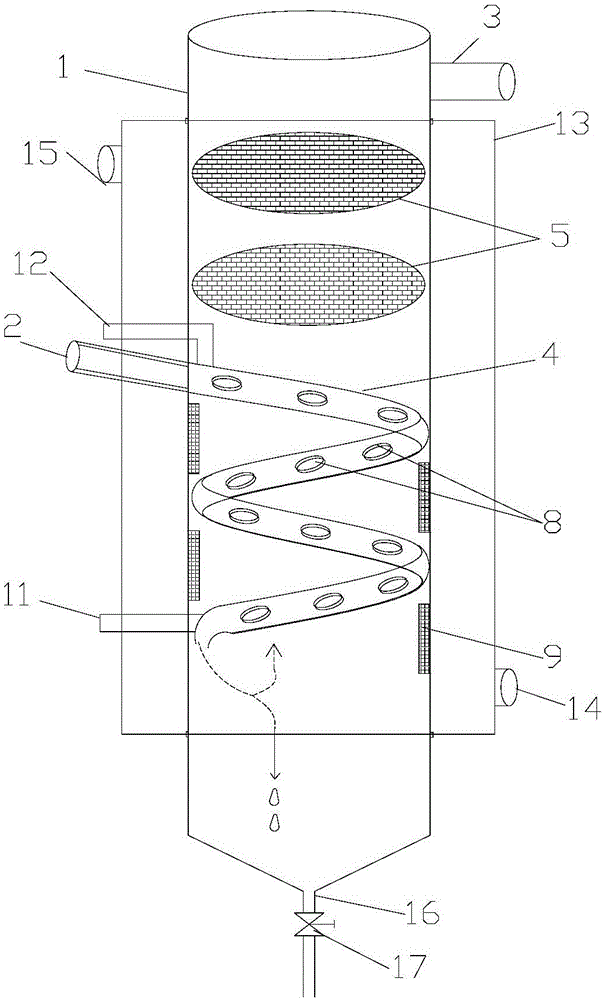

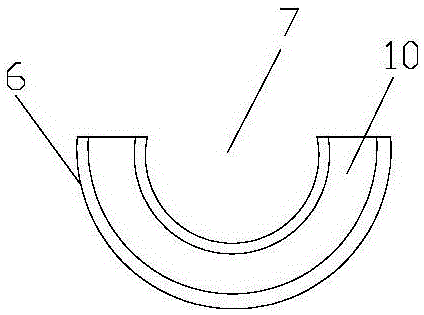

Three-shaft scattering device of viscous slurry

InactiveCN103521111AReduce the effect of negative pressureNegative pressure effect guaranteeRotary stirring mixersImpellerSlurry

The invention relates to a three-shaft scattering device of viscous slurry. The three-shaft scattering device comprises a round cylinder, a master stirring apparatus, a slave stirring apparatus, a guide blade, a pressure stabilizing plate, a waveform shear plate, a feeding hole, a discharge hole, a round hole sieve plate, a high-pressure water pipe and the like. According to the scattering device of the viscous slurry, the pressure stabilizing plate is arranged at the bottom and can automatically suck ore slurry into the round cylinder by pressure difference; a cylindrical rotary zone in the cylinder is eliminated by the shear plate arranged at the inner wall; the shear performance of the material is also improved; the stirring intensity of each stirring apparatus is effectively increased by the guide plate and three groups of mixing impellers arranged on stirring bearings; namely, the kinematic velocity of the material in the round cylinder is increased. Thus, effective dispersing of a viscous material is achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

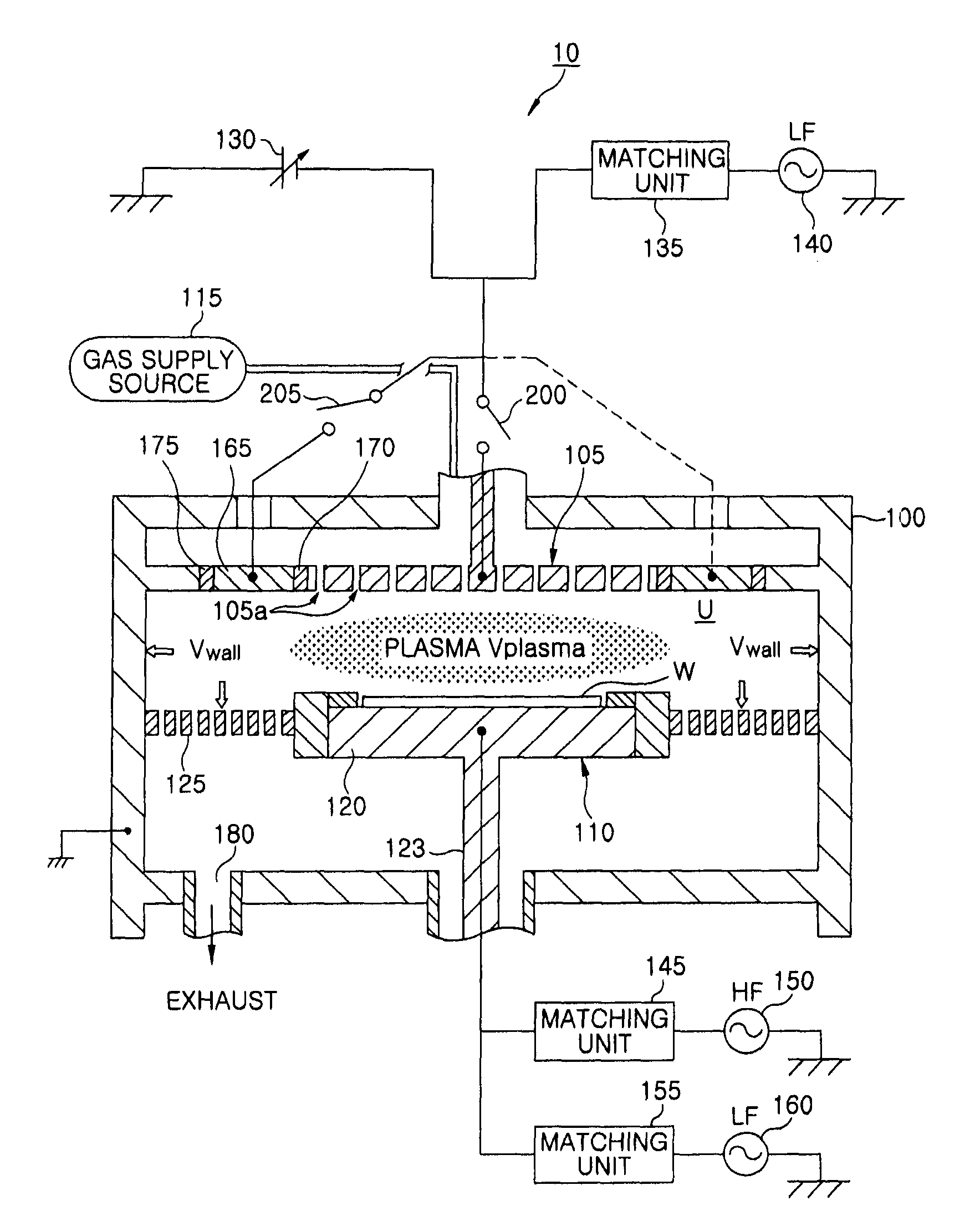

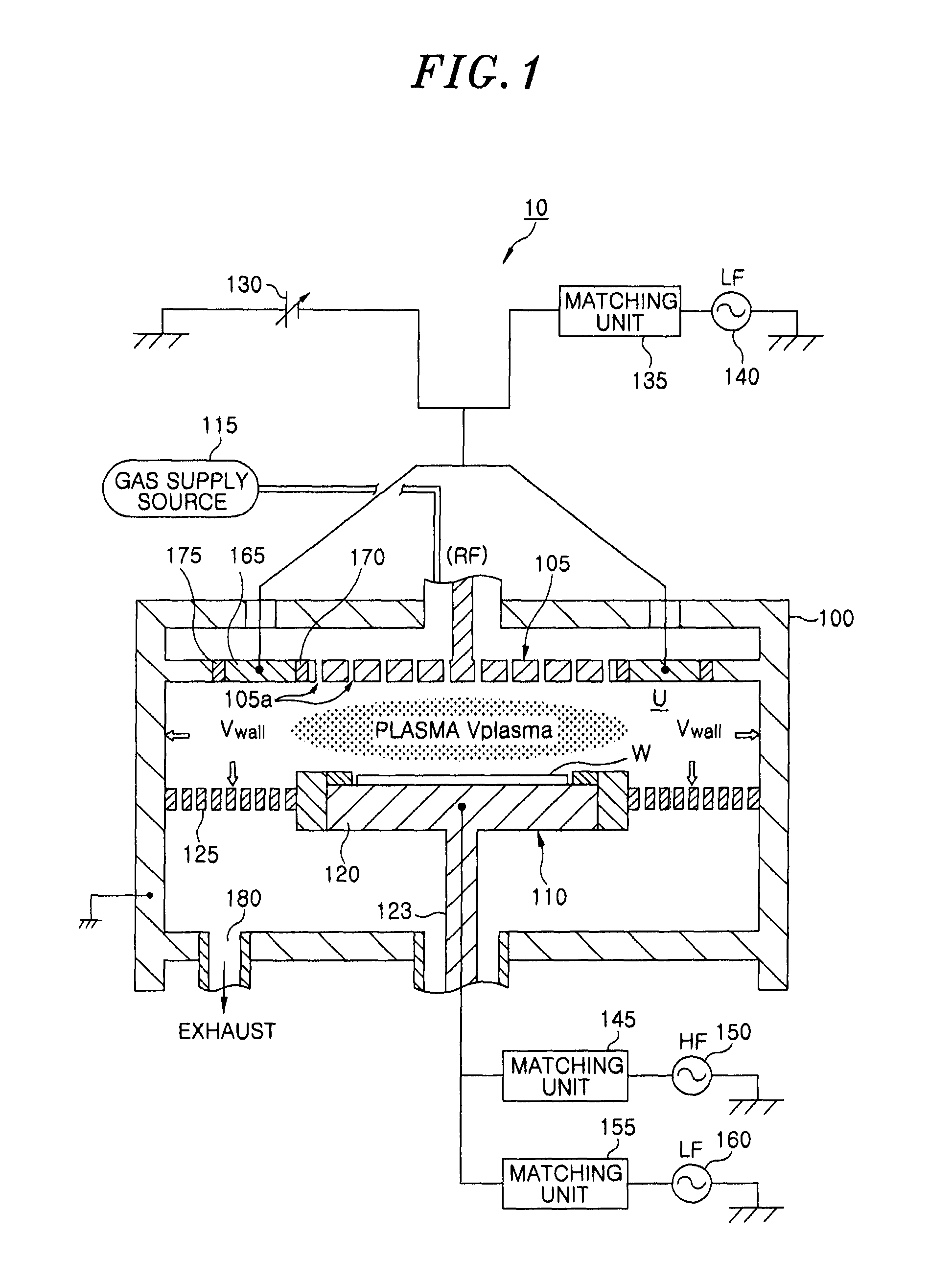

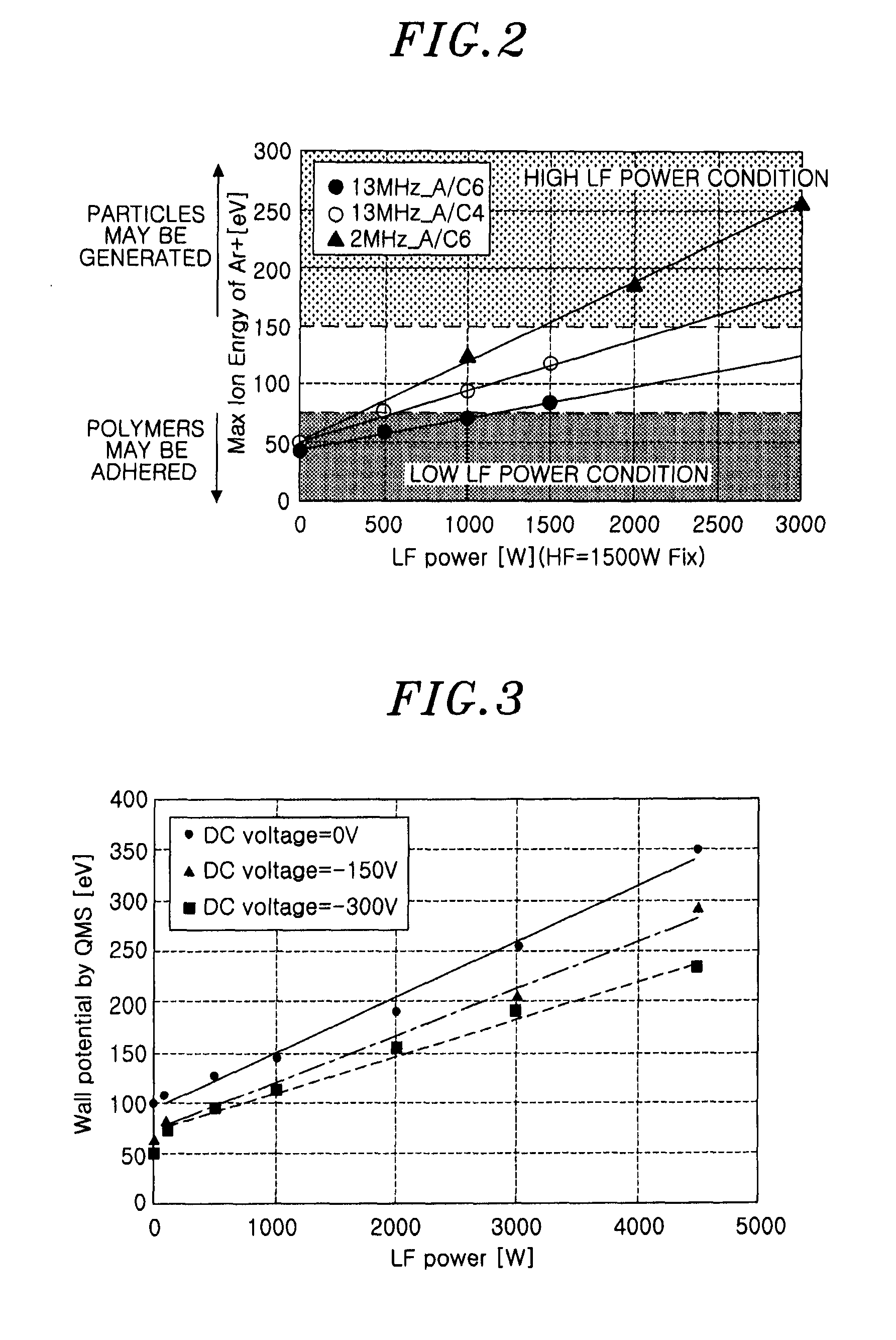

Plasma processing method and plasma processing apparatus

ActiveUS8545671B2Potential differenceImprove scalabilityElectric discharge tubesDecorative surface effectsHigh frequency powerAuxiliary electrode

Owner:TOKYO ELECTRON LTD

Brewing technology of Maotai-flavour Baijiu

InactiveCN106957771AReduce volumeEasy to collectAlcoholic beverage preparationMicroorganism based processesEngineeringMechanical engineering

The invention relates to a production technology of Baijiu, in particular to a brewing technology of Maotai-flavour Baijiu. The invention specifically discloses a brewing technology of Maotai-flavour Baijiu, which avoids the influence of gelatinized agglomerates on later period products through single picking up of the gelatinized agglomerates.

Owner:贵州省仁怀市茅台镇郑氏酒业有限公司

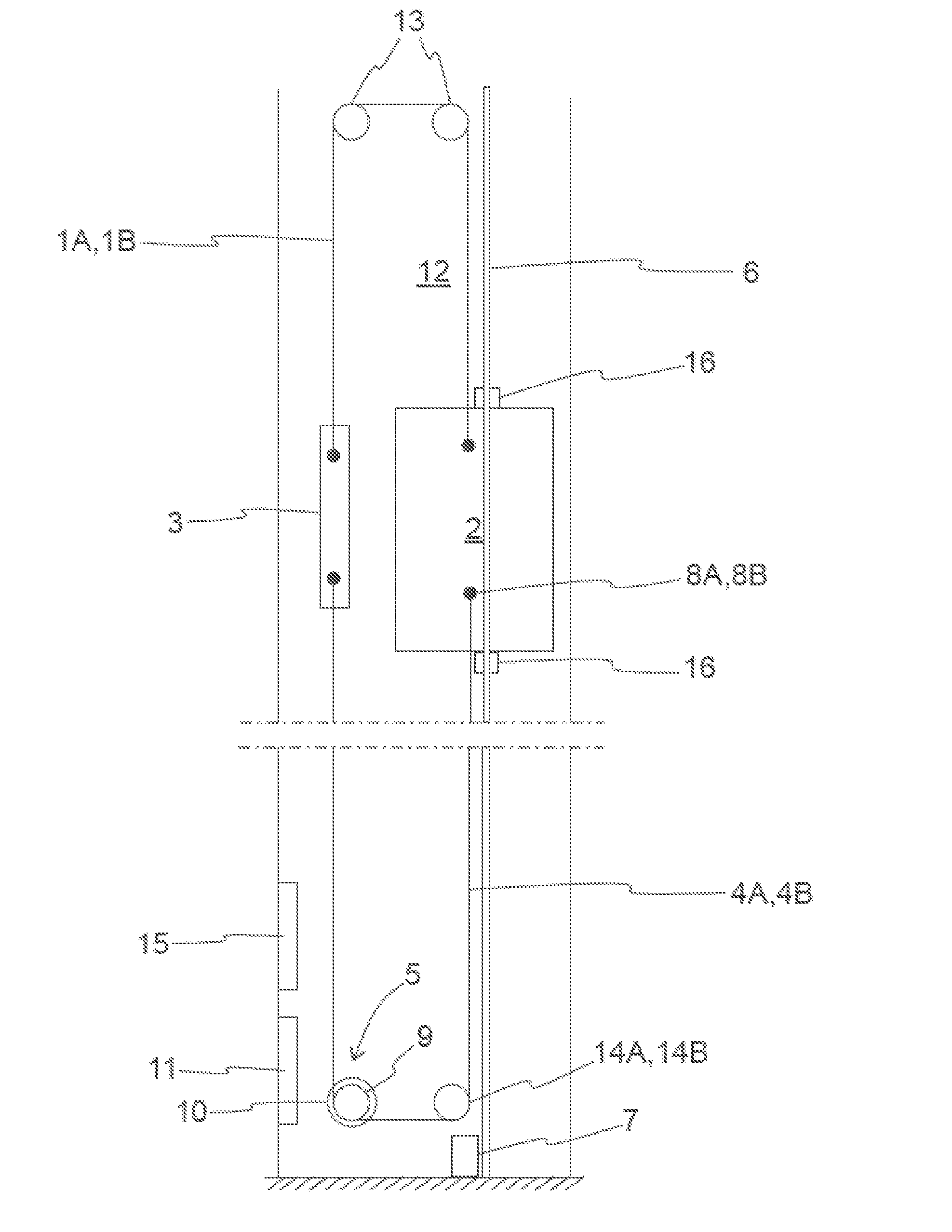

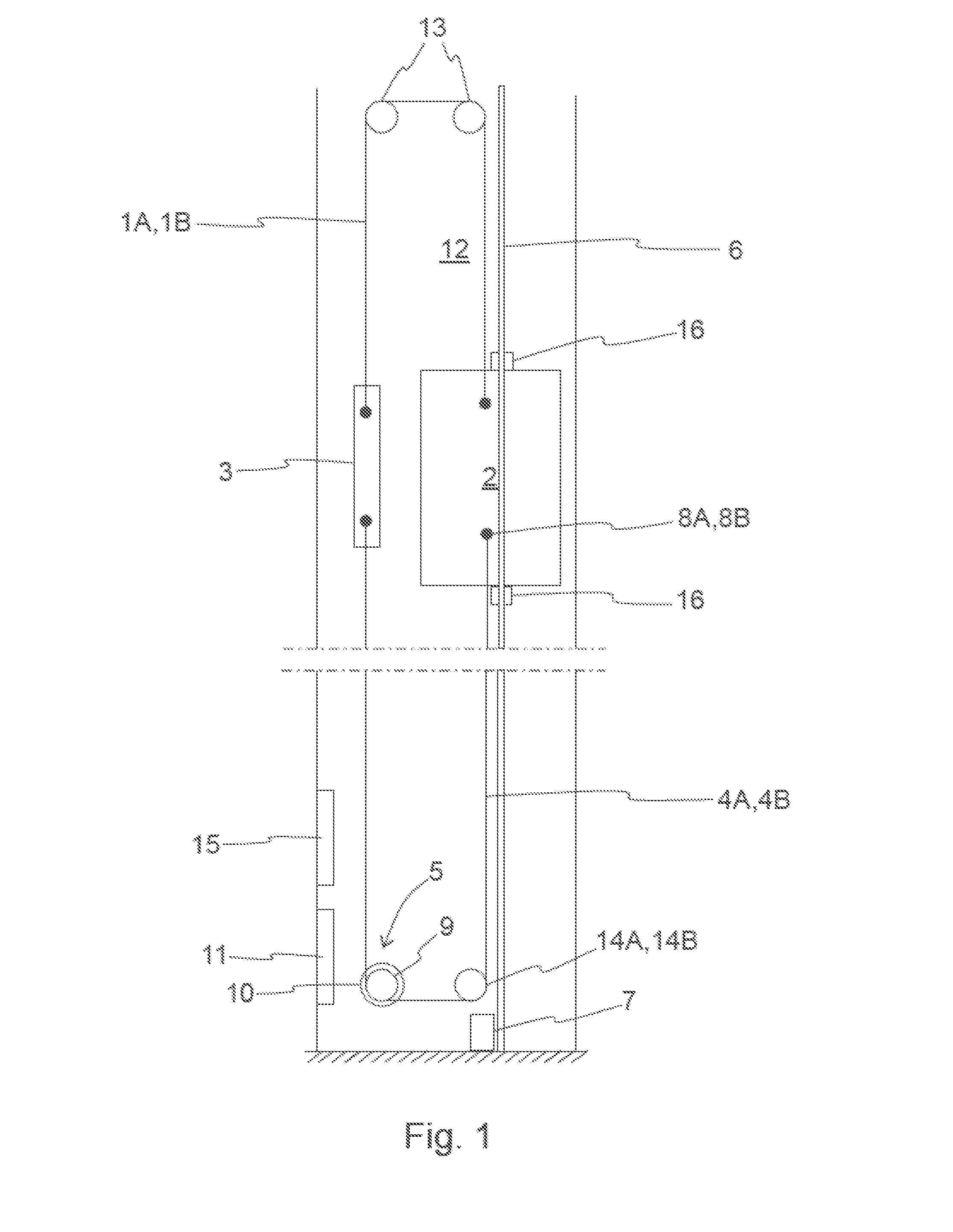

Elevator system

InactiveUS20140231180A1Space-efficiency can also be improvedSave spaceBuilding liftsPull forceElevator system

An elevator system includes an elongated suspension member, a load-receiving part suspended on the suspension member, a counterweight suspended on the suspension member for supporting the load-receiving part, an elongated traction member for exerting a pulling force on the load-receiving part and on the counterweight, a drive unit, with which the load-receiving part is driven by pulling the traction member and also one or more guide rails, along the path of movement determined by which the load-receiving part is moved. The drive unit is disposed to the side of the path of movement of the load-receiving part.

Owner:KONE CORP

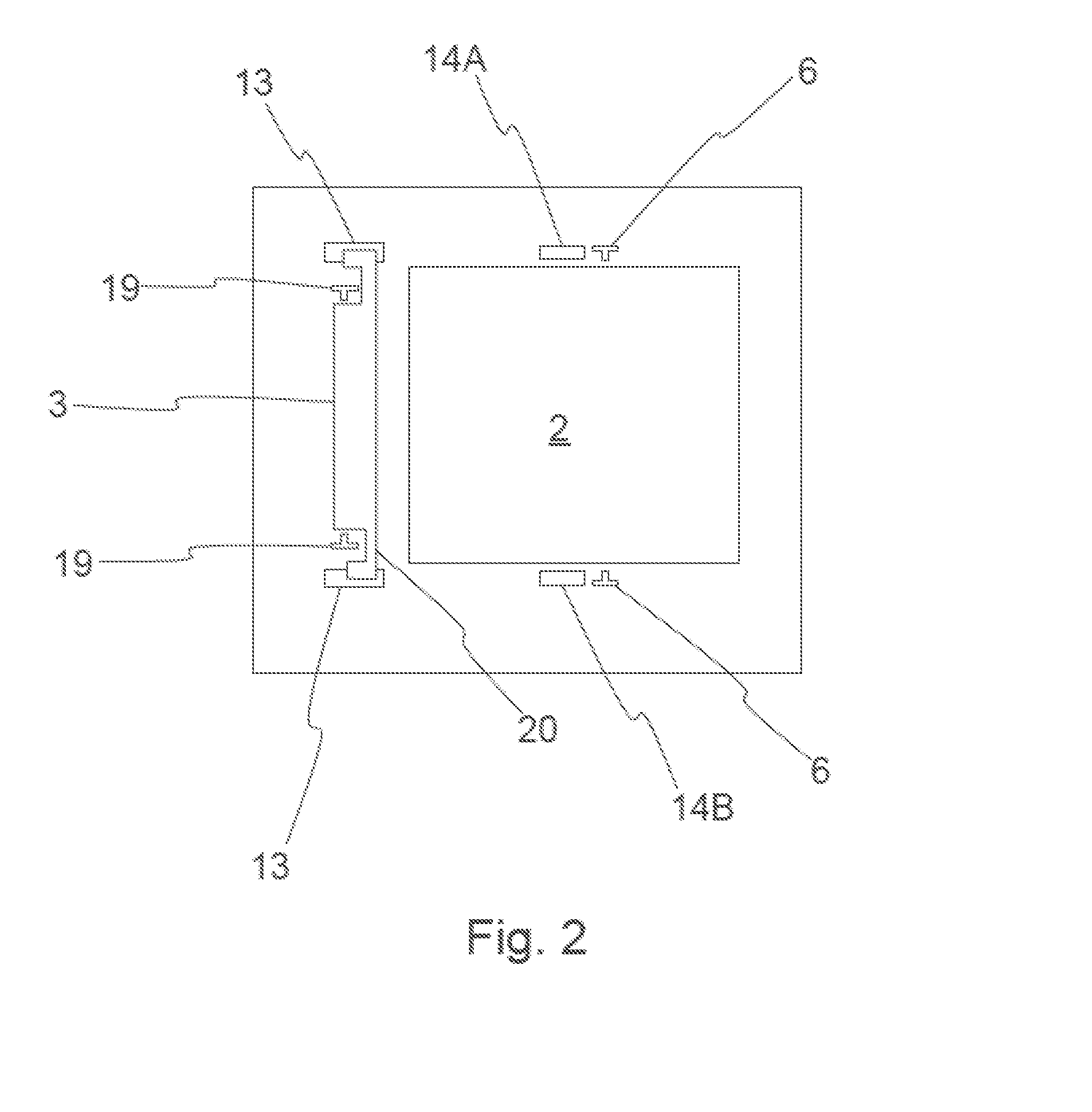

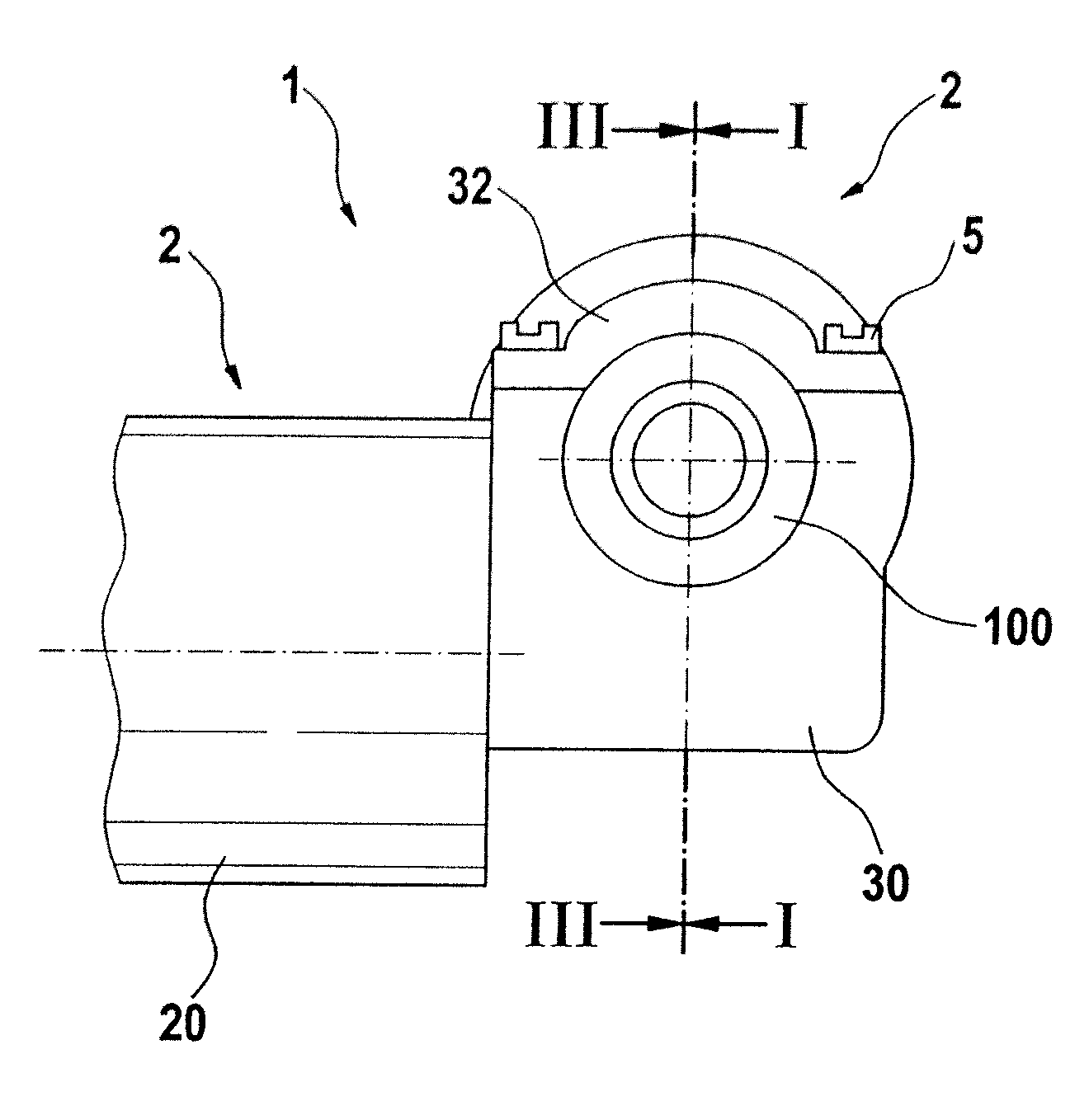

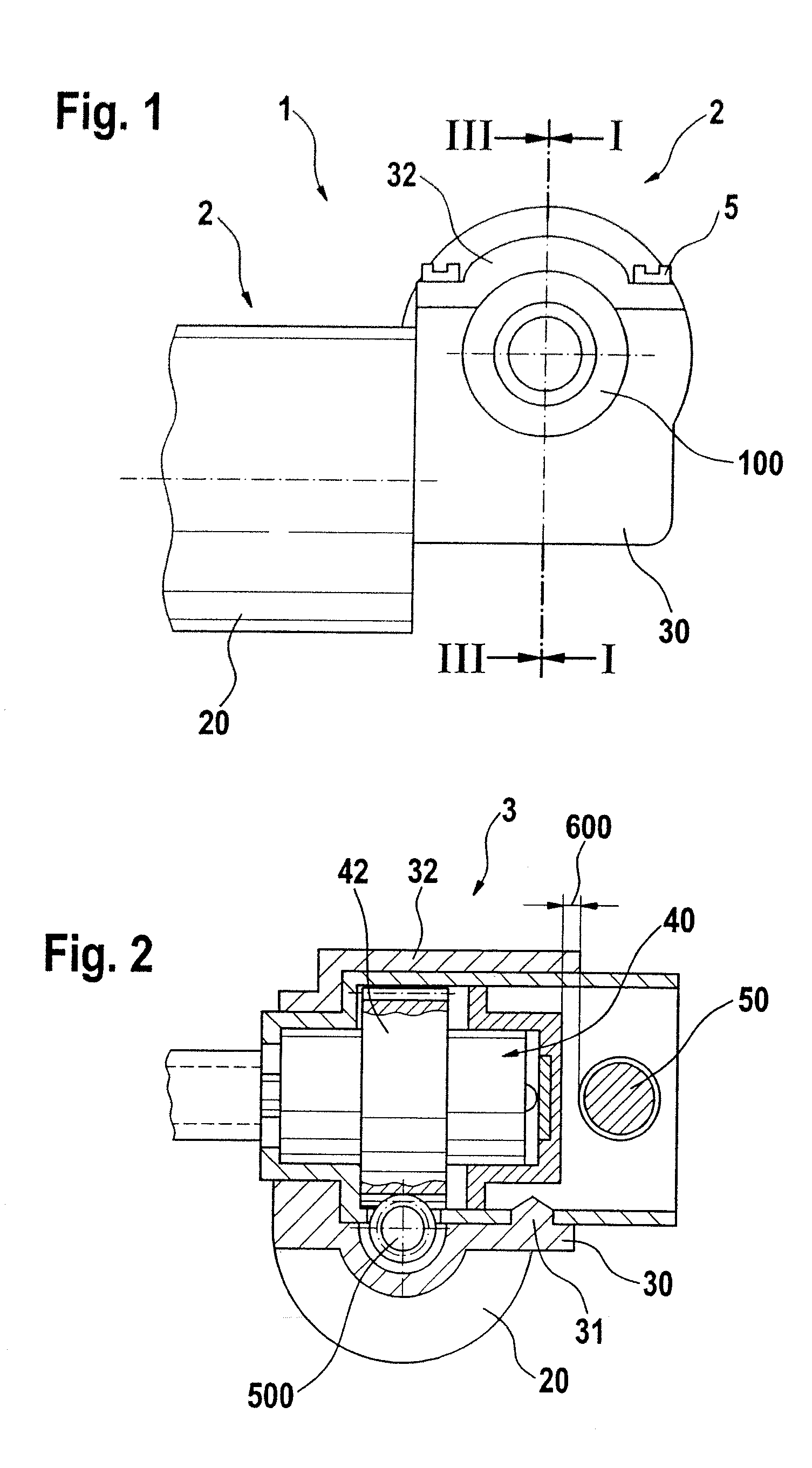

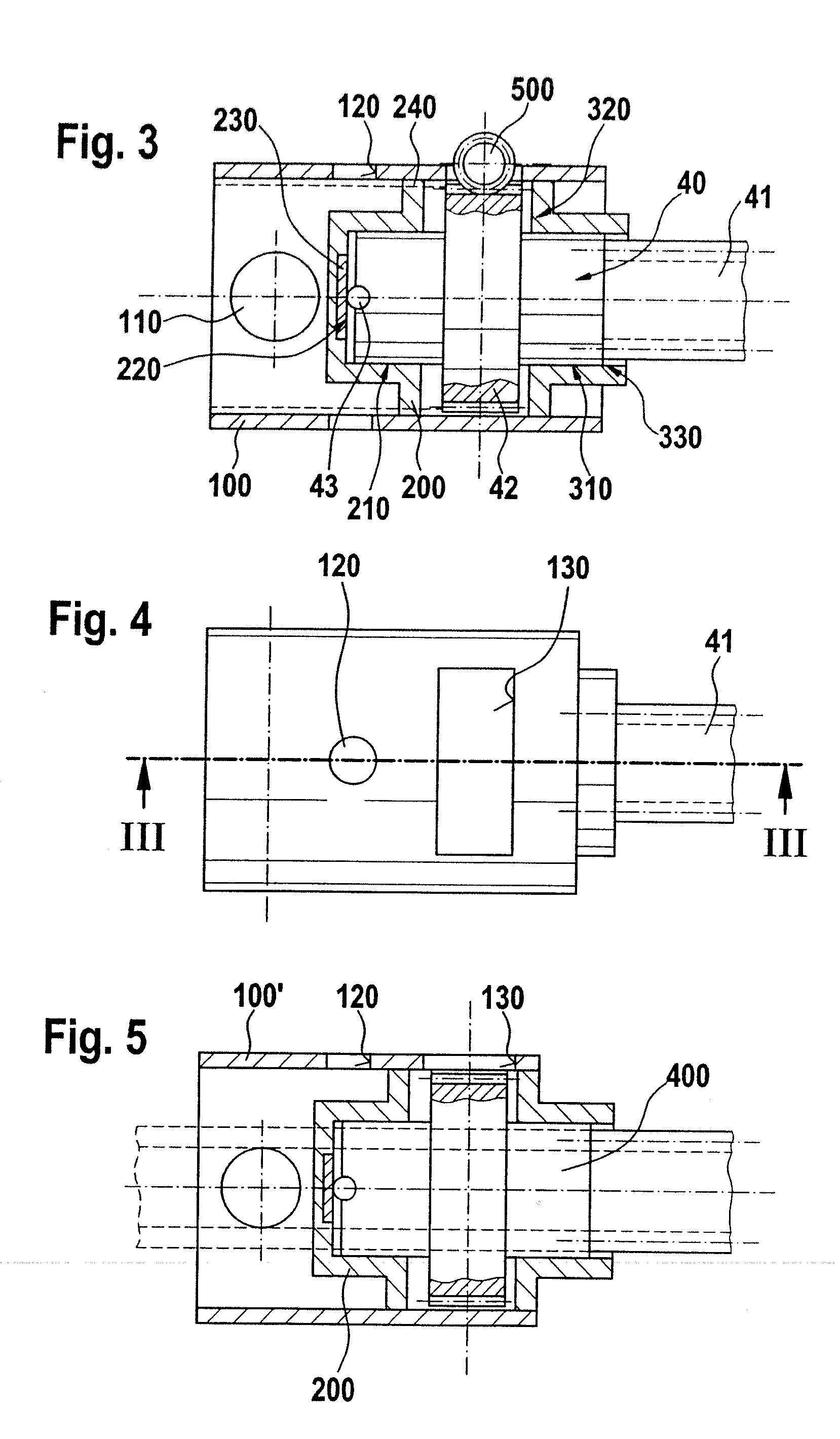

Gear/Drive Unit

InactiveUS20070289135A1Simple and compact structureIncrease the collision forceGearboxesMetal-working apparatusGear driveGear wheel

The invention relates to a gear drive unit (10)5, particularly for a seat adjuster or a power-assisted steering system, comprised of a spindle (40), on which a drive gear (42) that drives the spindle (40) is provided, a drive assembly (20), which drives the drive gear (42) by means of a driven element (500) and at least one device (30) on which the drive assembly (10)6 is at least flanged-mounted, and which operationally couples at least the driven element (500) and the drive gear (42). The invention provides that at least one additional support (100, 100′) is provided in which the drive gear (42) is mounted, and this support is fastened to the base part (50) and supports the device (30). 5 Translator's note: [sic] This appears to be a typographical error. The gear drive unit is designated “(1)” elsewhere in the document. 6 Translator's note: [sic] This appears to be a typographical error. The drive assembly is designated “(20)” elsewhere in the document.

Owner:ROBERT BOSCH GMBH

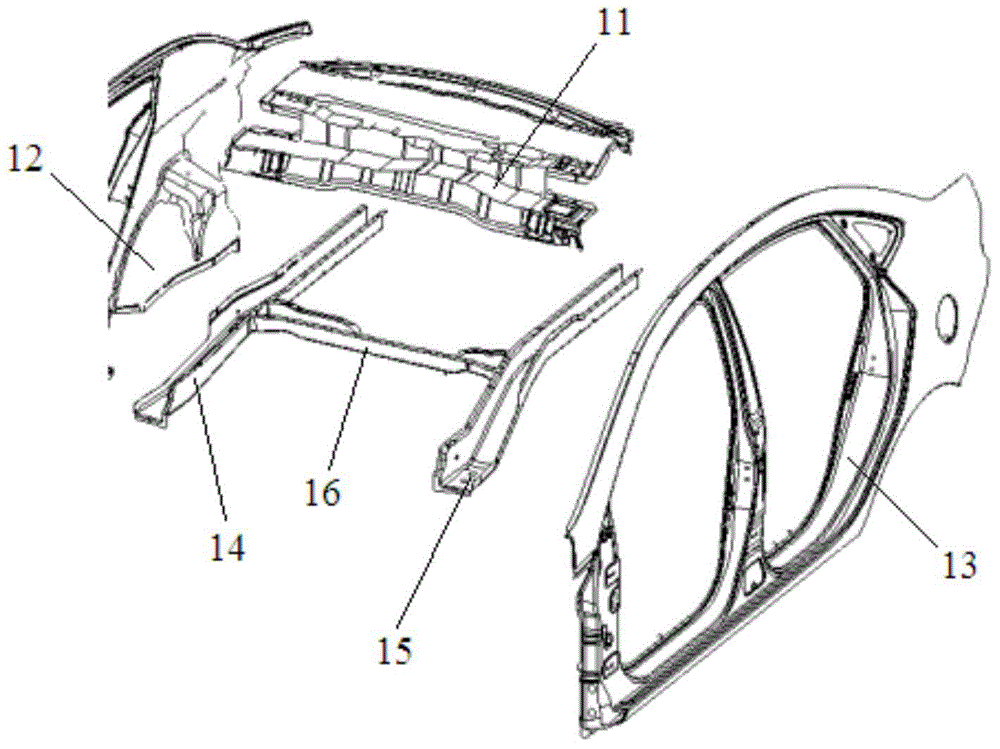

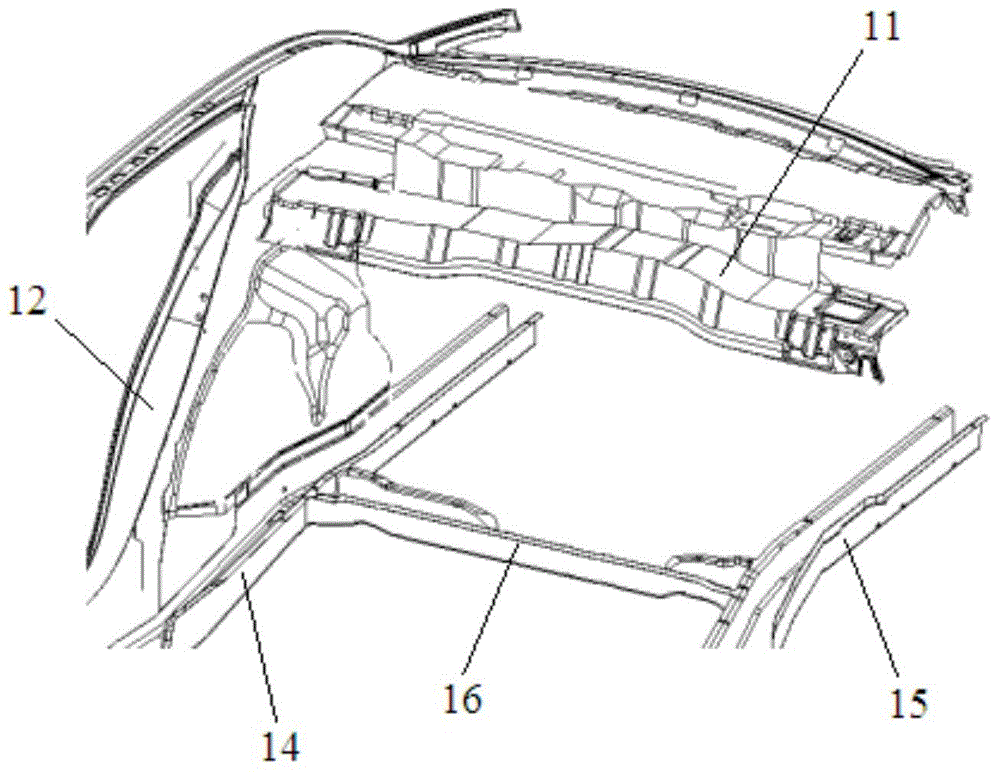

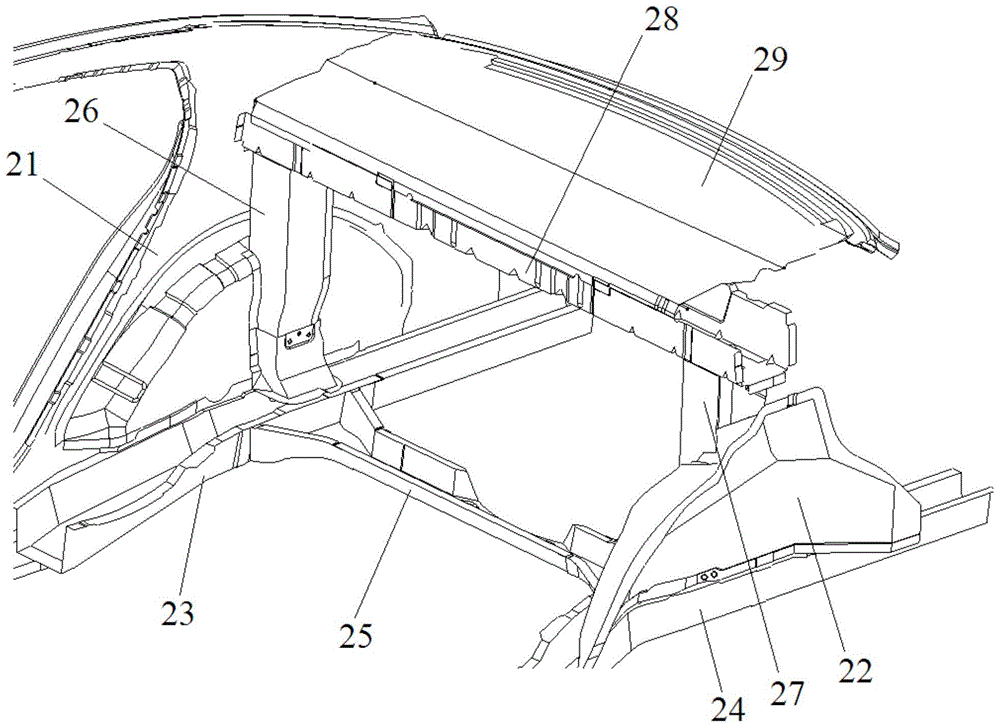

Automobile body and automobile

InactiveCN104670335AReduce harmIncrease the collision forceSuperstructure subunitsMonocoque constructionsRear-end collisionAutomotive engineering

The invention discloses an automobile body, comprising a left-side assembly (21), a right-side assembly (22), a rear floor assembly, a coatrack assembly and a coatrack vertical beam, wherein the rear floor assembly and the coatrack assembly are both connected between the left-side assembly (21) and the right-side assembly (22); two ends of the coatrack vertical beam are respectively fixed with the coatrack assembly and the rear floor assembly. According to the automobile body, when an automobile is subject to rear-end collision, not only is the impact force applied on the rear floor assembly transferred to the front of the automobile body through the rear floor assembly, but also the impact force can be transferred to the coatrack assembly through the coatrack vertical beam, so that the transfer direction of the impact force is increased, the impact force is dispersed as quickly as possible, and passengers in the back row suffer from smaller injury in the rear-end collision process. The invention also discloses an automobile.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

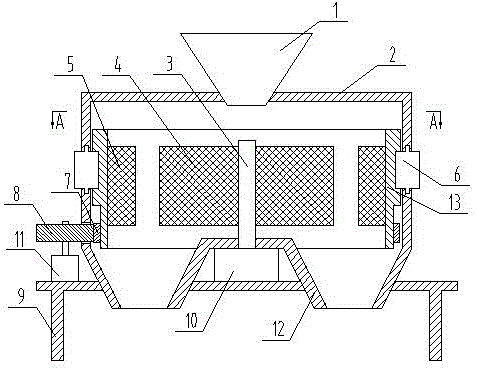

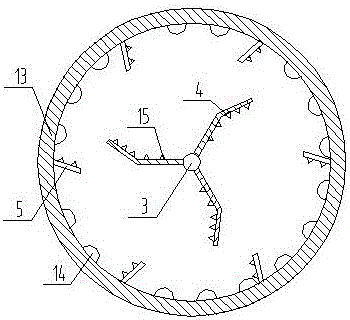

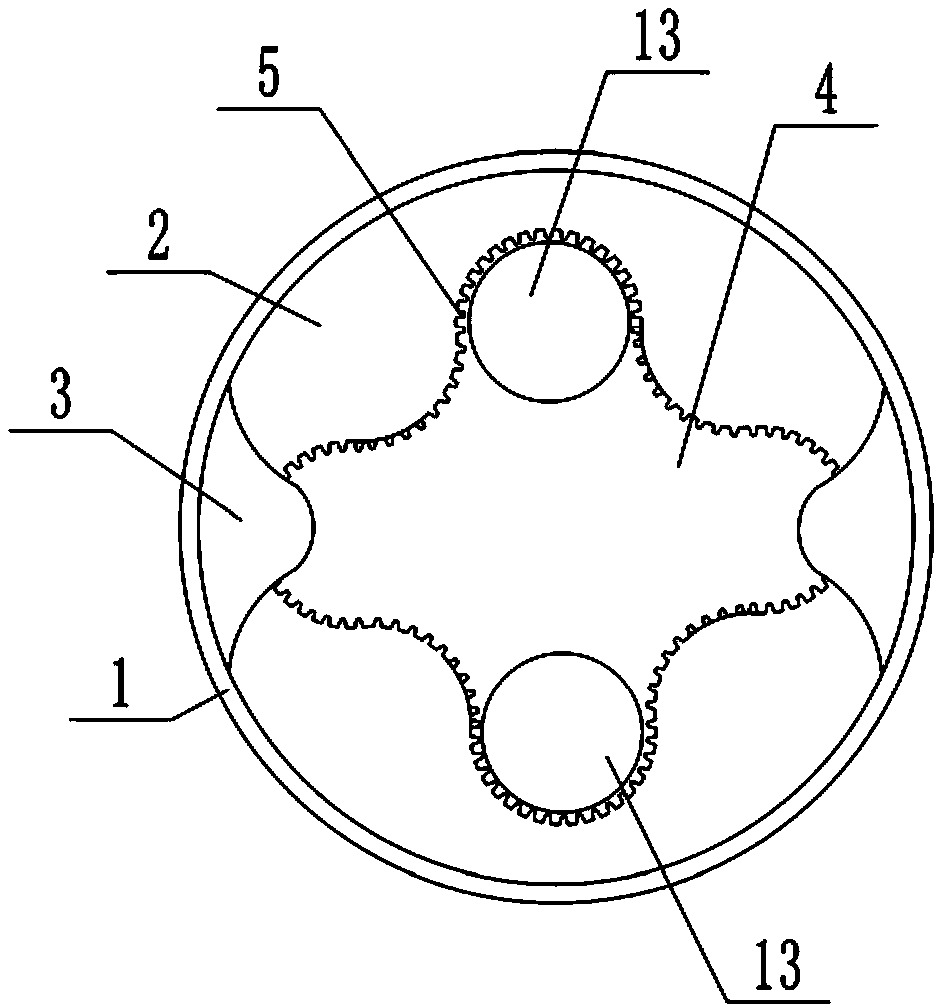

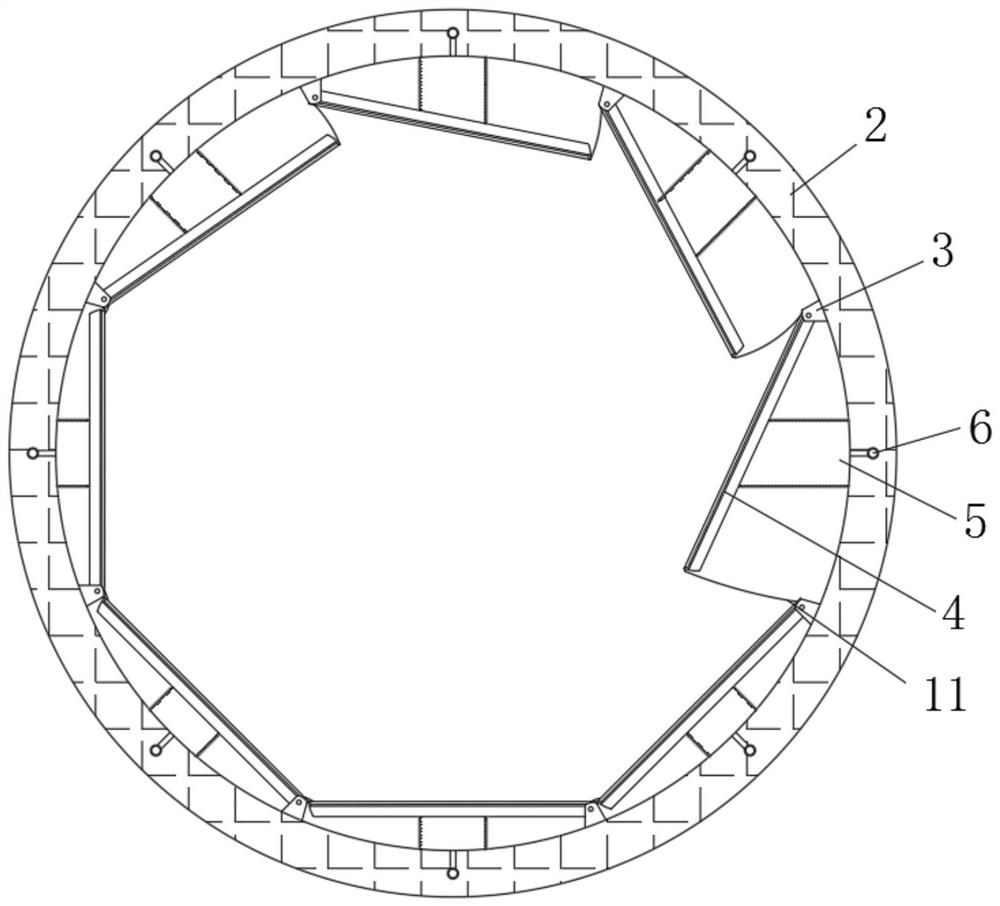

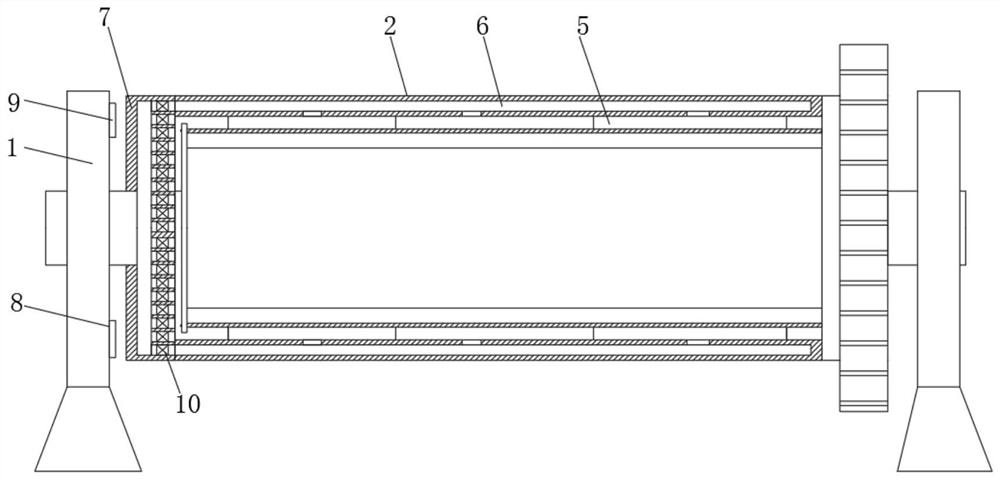

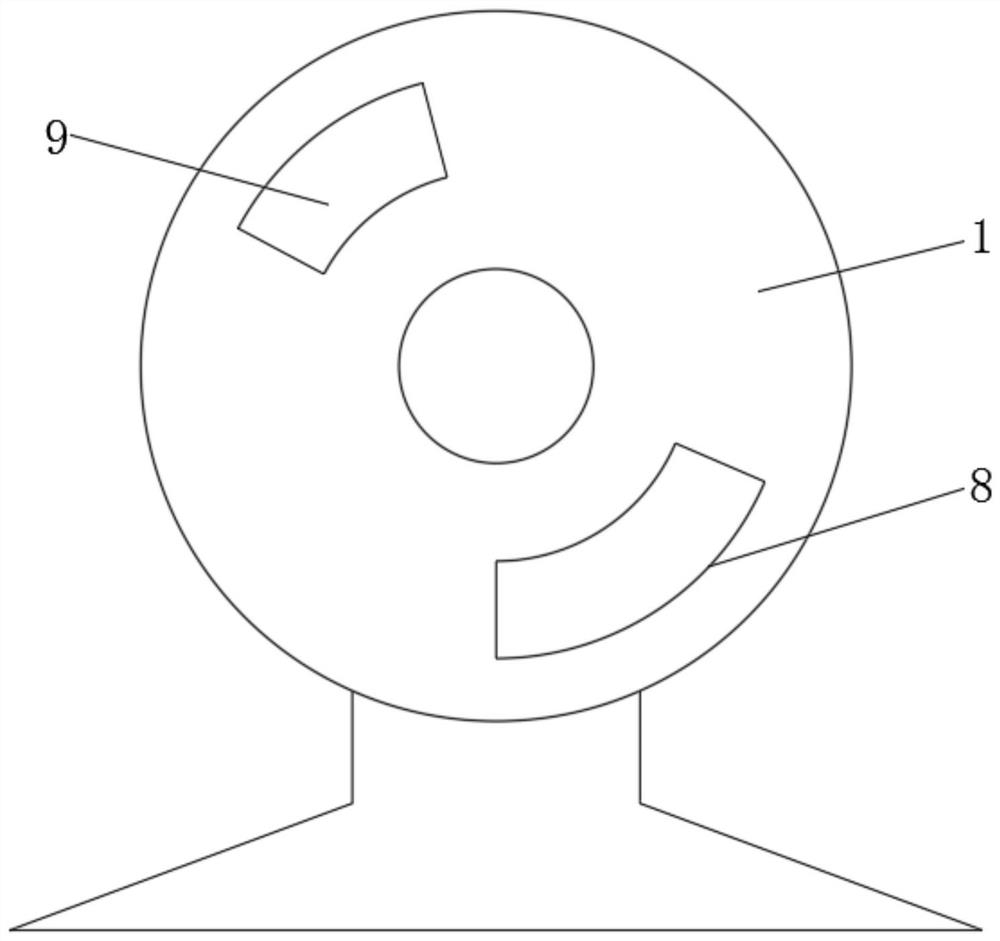

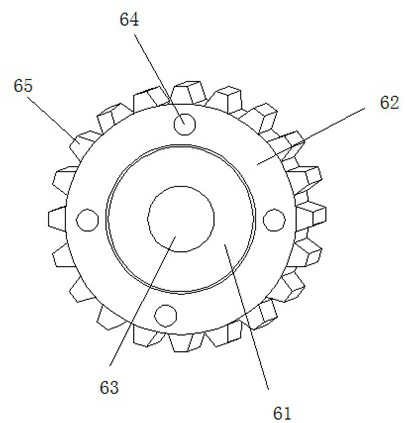

Vertical shaft impact type crusher

The invention relates to a vertical shaft impact type crusher. A forward-rotating motor is arranged on a frame and is connected with one end of a rotating shaft, the other end of the rotating shaft penetrates through the bottom wall of a body, is arranged in a cavity of the body and is uniformly provided with forward-rotating rib plates; a barrel is arranged in the cavity of the body; rolling shafts are uniformly arranged on side walls of the body; the rolling shaft and the barrel are assembled together in a matched manner; reverse-rotating rib plates are uniformly arranged on the inner side wall of the barrel; ring gears are mounted on the outer side walls of the barrel; the frame is further provided with a reverse-rotating motor; and a gear is assembled on the reverse-rotating motor, penetrates through an opening and is matched with the corresponding ring gear. By the reverse-rotating rib plates of which the rotation direction is opposite to that of the forward-rotating rib plates, thrown-out stones are further impacted and crushed, and after the stones are impacted and crushed, the refining effect is good.

Owner:CHENGDU DAHONGLI MACHINERY

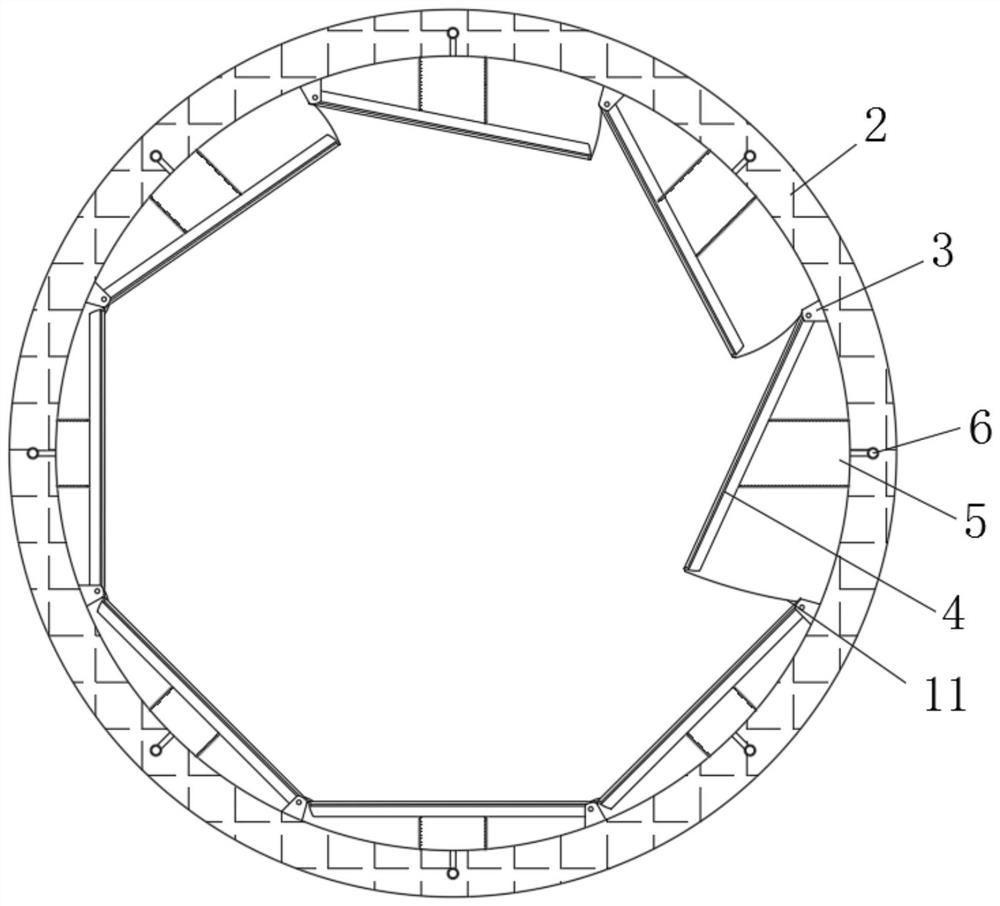

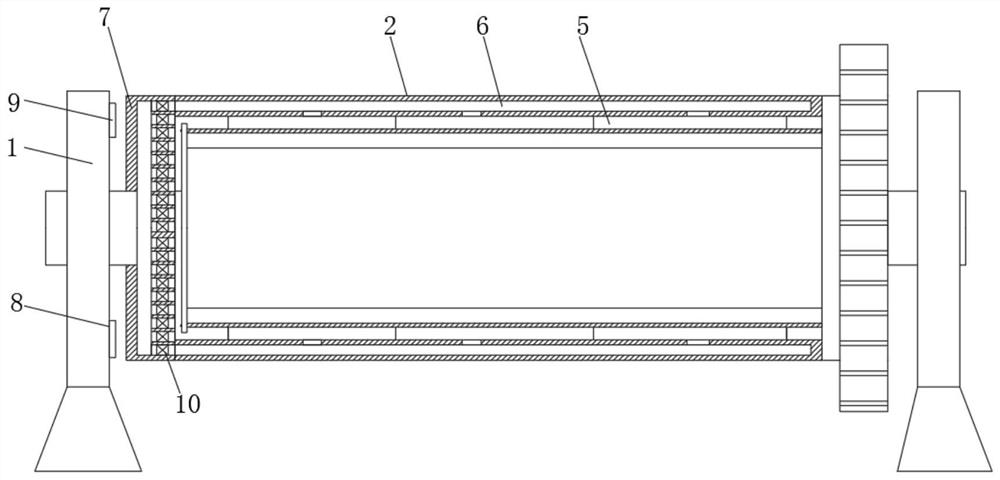

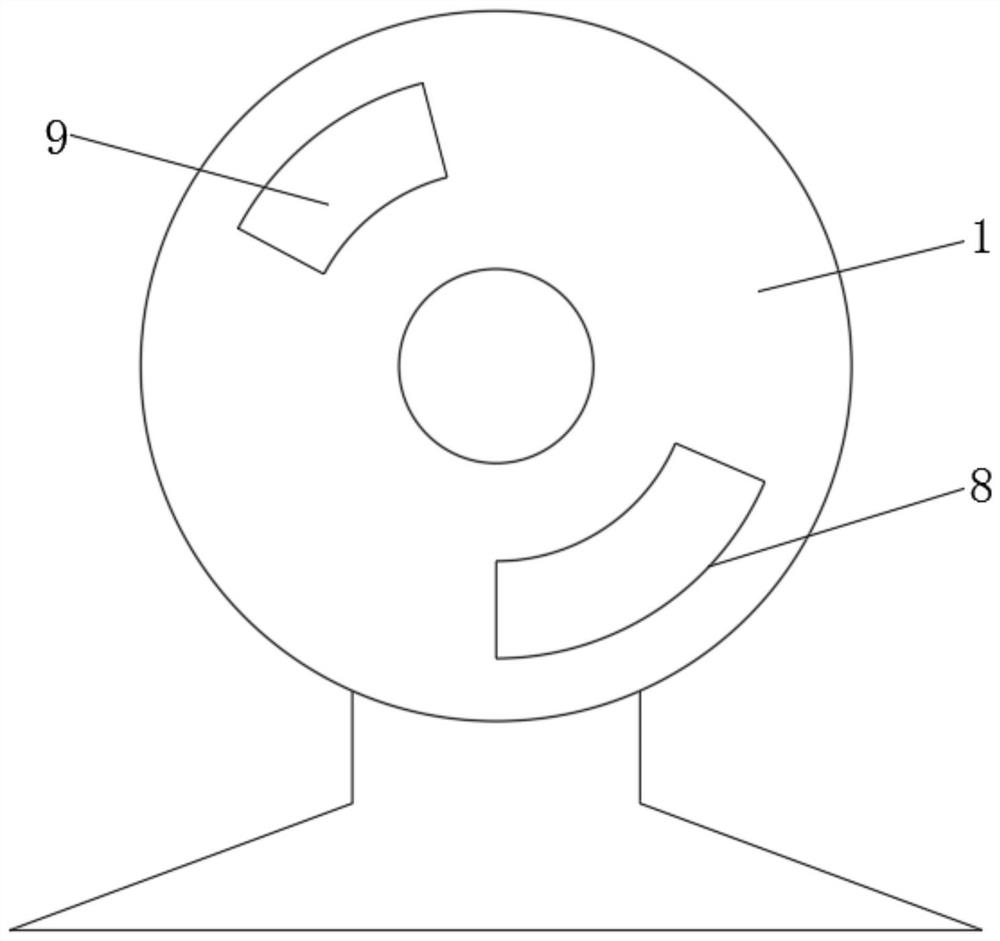

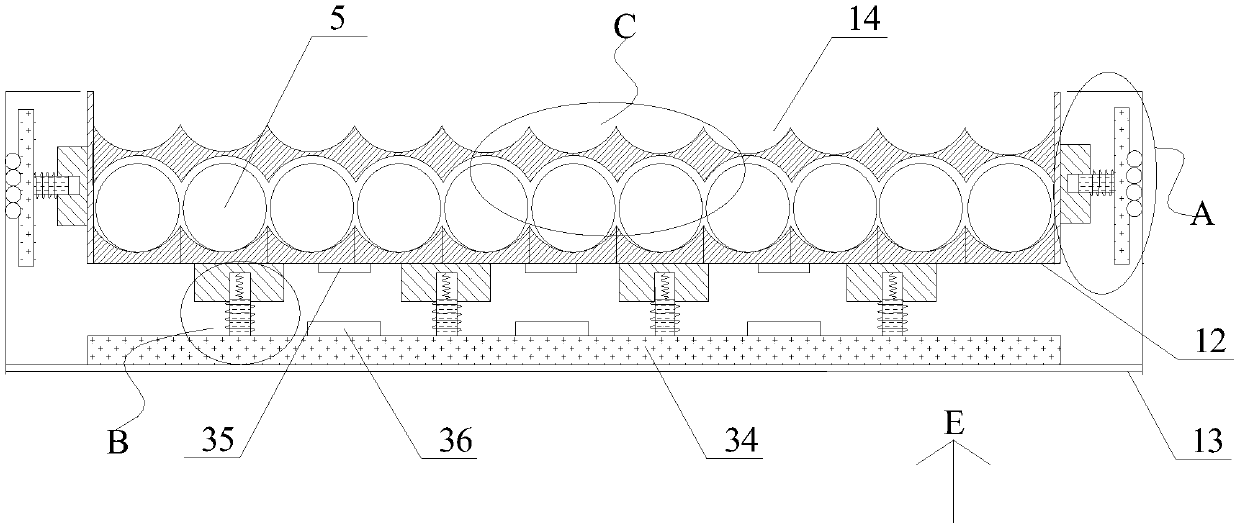

Full-automatic grinder for ore mining

ActiveCN112756072AExpand the speed range of useWide GrindingGrain treatmentsMining engineeringMechanical engineering

The invention relates to the technical field of grinder equipment, and discloses a full-automatic grinder for ore mining. The full-automatic grinder comprises a rack and a roller, wherein the inner wall of the roller is connected to lining plates through connecting blocks, a driving bag is arranged between each lining plate and the inner wall of the roller, and each driving bag is filled with dilatant fluid. According to the full-automatic grinder for ore mining, through hinge joint of the lining plates, when mineral aggregates are in a rising state, due to the fact that the sides, away from the connecting blocks, of the lining plates are low, formed inclined planes support the mineral aggregates, and slipping of the mineral aggregates is effectively reduced; when the mineral aggregates reach the high position, the lining plates are opened to actively enable the mineral aggregates to be separated, separation of the mineral aggregates and the roller at a high speed can be guaranteed, and the use rotating speed range of the grinder is expanded; and the collision force is improved by means of the characteristic that the dilatant fluid is approximately fixed at the moment of expansion, meanwhile, the acting force buffering force can be dispersed globally, the damage generated by the impact force is greatly reduced, and meanwhile, the noise generated by the impact can be greatly reduced.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

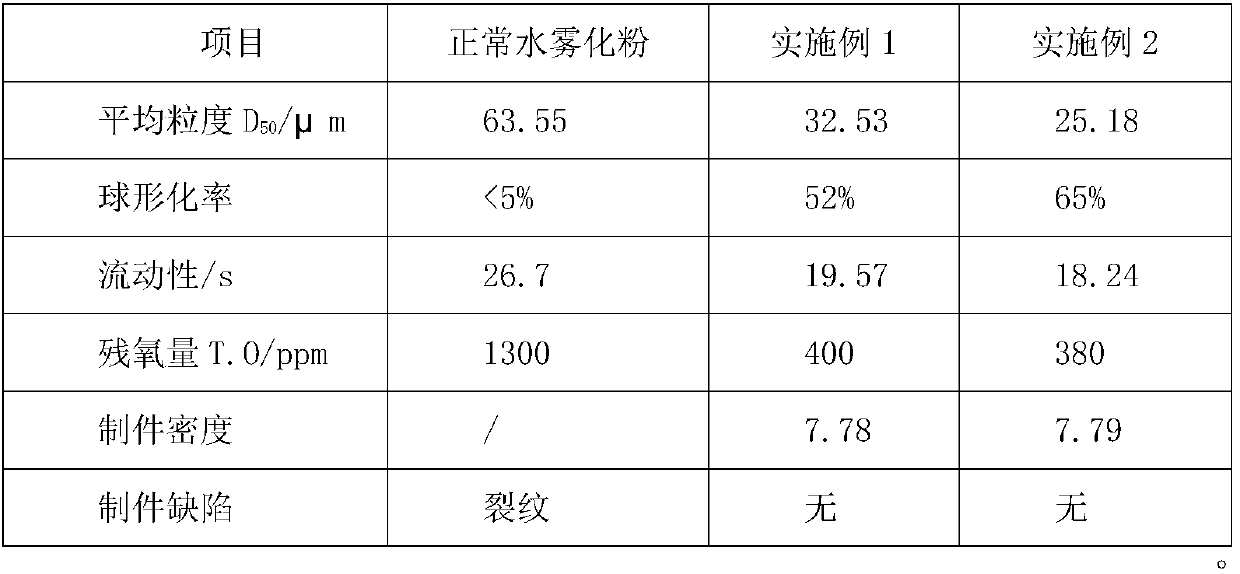

Manufacturing method of powder materials for additive manufacturing

ActiveCN107716935AUniform particle sizeImprove particle size uniformityTransportation and packagingMetal-working apparatusHigh pressureImpurity

The invention discloses a manufacturing method of powder materials for additive manufacturing. The method is characterized in that a minus 1000-mesh powder material is separated from ordinary water atomized iron powder, and the minus 1000-mesh powder material is conveyed into an atomizer through a high pressure air current and is adopted as core particles of a high-pressure cooling water medium toimprove fine powder rate and sphericility of powder material products. According to the method, minus 1000-mesh iron powder is adopted as a nucleation center and is dispersed in high-pressure high-speed atomized water, collision strength is improved, reaction free energy is changed when iron powder collides with molten iron or molten steel, solidification time is shortened while atomization efficiency is improved, and iron powder or steel powder with high sphericility and uniform particle size distribution is obtained; the adopted minus 1000-mesh iron powder is a low-value product in the normal production process and can be obtained through normal separation, the yield of a core product is increased while the utilization rate of the low-value product is increased, increase of impurity elements is avoided, and follow-up special treatment is not required; and the method is low in cost when utilized to manufacture iron powder or steel powder, and manufacturing cost of additive manufacturing products is greatly reduced.

Owner:ANSTEEL BEIJING RES INST

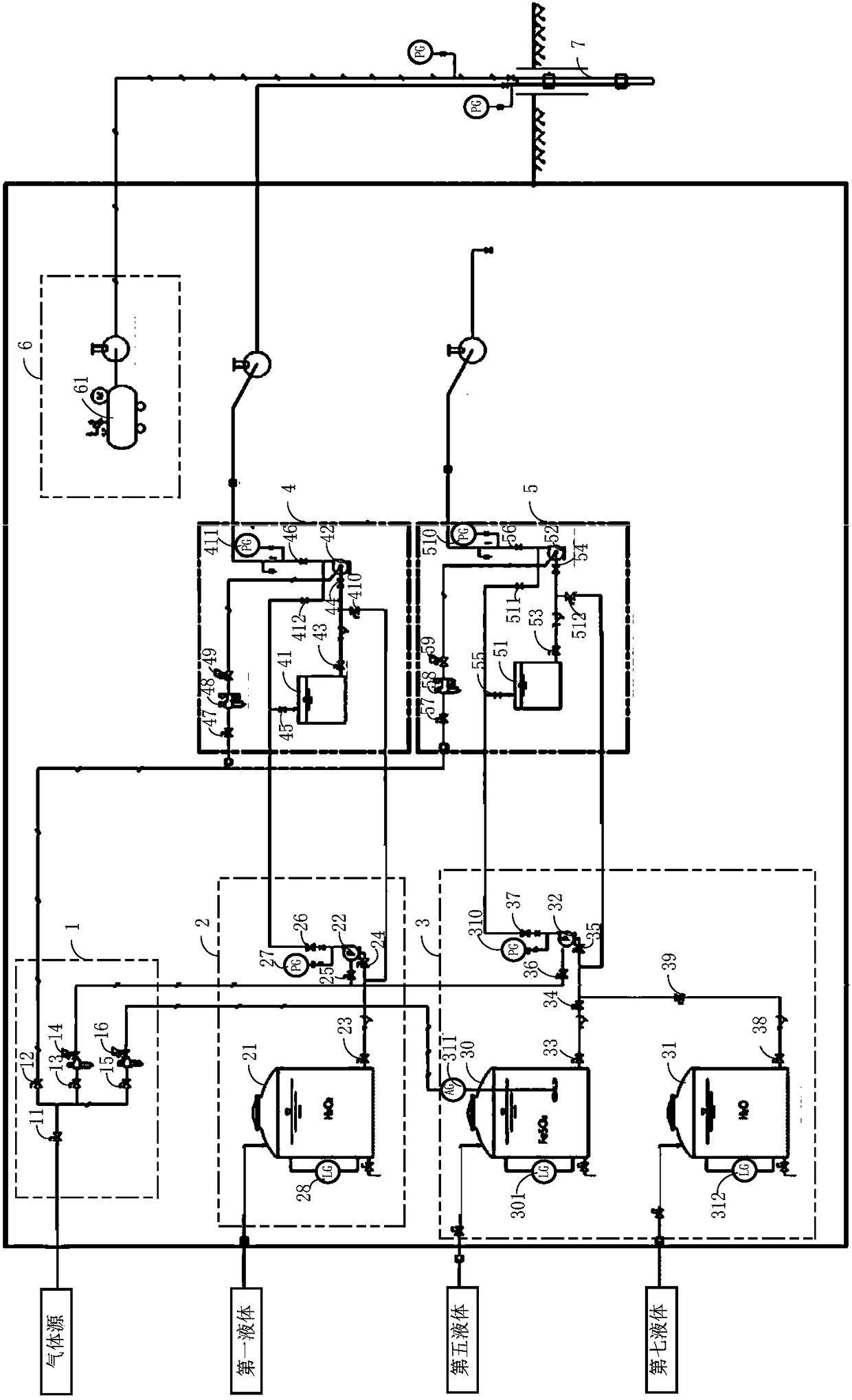

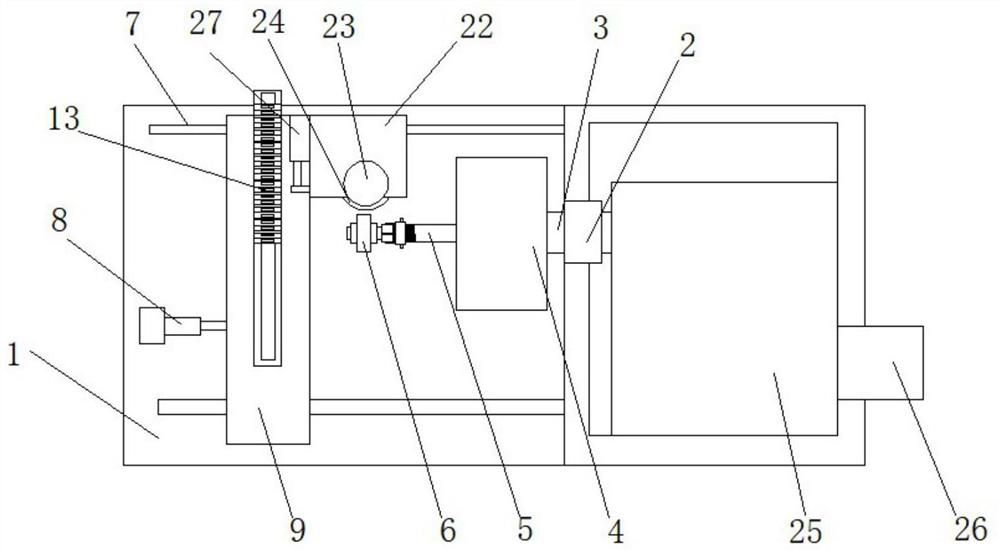

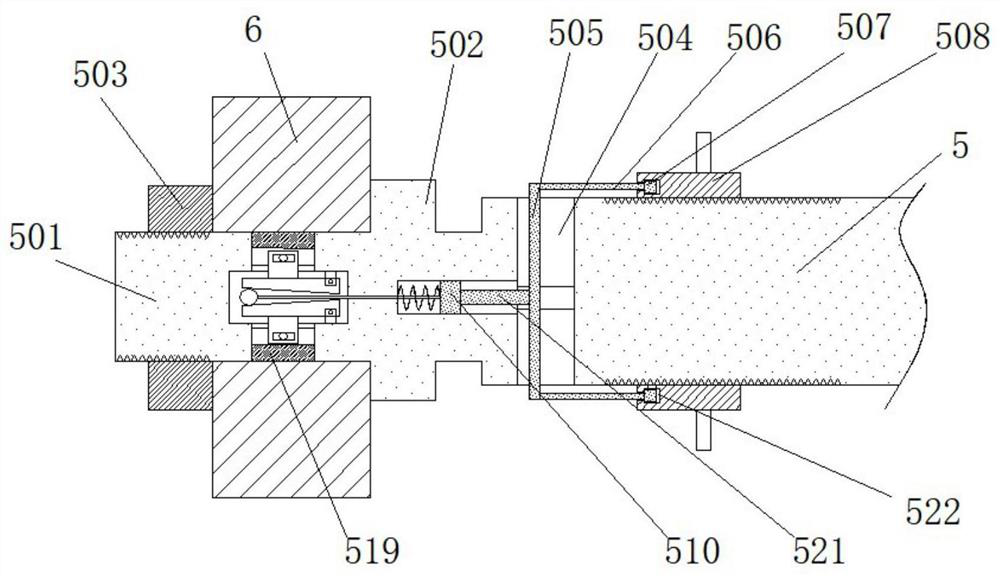

High-pressure injection device for contaminated soil and underground water as well as vehicle

ActiveCN108405584AEfficient repairIncrease the collision forceContaminated soil reclamationGrain treatmentsAir compressionPollution soil

The embodiment of the invention provides a high-pressure injection device for contaminated soil and underground water as well as a vehicle. The high-pressure injection device comprises an air supply device, a first liquid medicine supply device, a second liquid medicine supply device, a first liquid medicine injection device, a second liquid medicine injection device, an injection part and an aircompression device, wherein through the air supply device and the first liquid medicine supply device, first liquid medicine is injected into the first liquid medicine injection device; through the air supply device and the second liquid medicine supply device, second liquid medicine is injected into the second liquid medicine injection device; through the first liquid medicine injection device and / or the second liquid medicine injection device; the first liquid medicine and / or the second liquid medicine are / is conveyed to the injection part; through the air compression device, air is conveyedto the injection part; and through the injection part, the air, the first liquid medicine and / or the second liquid medicine are / is injected into soil. Consequently, the problem that the ground rigidity and the ground endurance are reduced due to a conventional tubular rock breaking device, and then a surface bump is formed and adjacent structures are destabilized can be solved.

Owner:JIU

Motor vehicle collision device with jet energy consumer

InactiveCN102107633AReduces liquid pressure peaksReduce peak accelerationBumpersRear-end collisionEngineering

The invention provides a motor vehicle collision device with a jet energy consumer, comprising a piston cylinder, at least one screw hole joint, at least one high pressure connecting pipe and a jet energy consumer, wherein the jet energy consumer comprises high pressure buffer chambers, low pressure buffer chambers, shuttle valves, valve cylinders, valve cylinder end covers, screw holes and bolts with holes; the screw hole joint is orderly connected in a through hole of the piston cylinder along the vertical wall of the piston cylinder; one end of the high pressure connecting pipe is connected with the screw hole joint while the other end of the high pressure connecting pipe is connected with the screw hole through the corresponding bolt with hole; and each shuttle valve is arranged in the corresponding valve cylinder. The device provided by the invention can implement first soft collision and then hard collision of the vehicle body during the collision process, can automatically adapt to 100% front side collision and deflection collision, and can prevent the front side collision firstly and prevent the rear-end collision, guarantee the vehicle body at a stretch state, and greatly improve the safety of the motor vehicle.

Owner:凌建军

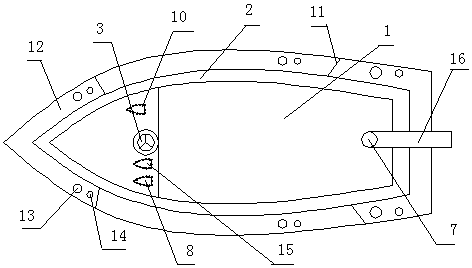

Anti-knocking-down and anti-side-turning bumper boat

InactiveCN108128421AEasy to identify each otherAvoid bumpingCollision preventionSpecial purpose vesselsJet engineSteering wheel

The invention relates to the technical field of manufacturing of a bumper boat, in particular to an anti-knocking-down and anti-side-turning bumper boat. The knocking-down and anti-side-turning bumperboat is provided with a hull and an airbag collision body. The airbag collision body is arranged around the bottom of the hull, and a steering wheel and a power drive device are arranged in the hull.The knocking-down and anti-side-turning bumper boat is characterized in that air outlet nozzles with outlets facing downward are sequentially arranged on the periphery of the lower portion of the airbag collision body; the arrangement shape of the air outlet nozzles is similar to the shape of the airbag collision body, and each air outlet nozzle communicates with an exhaust pipe of a jet engine through an air outlet pipe; an intake pipe of the jet engine is arranged above the stern of the hull, and an electromagnetic valve is arranged on each air outlet pipe; an electromagnetic valve controlswitch is arranged on an operation panel near the steering wheel in the hull; the electromagnetic valve control switch and each air outlet nozzle are arranged in similar shapes, and the electromagnetic valve control switch controls air outlet of the air outlet nozzles at the same position. The opening and closing of the electromagnetic valve are controlled to control air outlet of the air outlet pipes by the electromagnetic valve control switch and the knocking-down and anti-side-turning bumper boat has the advantages of convenient use, high safety, great fun and the like.

Owner:梁书鸣

Gear meshing defective product detection device

The invention relates to the technical field of gear processing, and in particular, relates to a gear meshing defective product detection device which comprises a base, a driving mechanism, a positioning mechanism, a clamping mechanism and a tooth aligning mechanism; the driving mechanism and the positioning mechanism are arranged on the two sides of the top of the base respectively, the clamping mechanism is arranged on one side of the driving mechanism, and the tooth aligning mechanism is arranged on the positioning mechanism; and the positioning mechanism comprises a guide unit and a detection unit, and the clamping mechanism comprises a workpiece fixing unit and a locking unit. A gear is subjected to tooth alignment processing by a turbine rod, so that the gear can be quickly processed after tooth alignment of the gear is unqualified, a rack capable of floating and moving can be self-adaptively meshed with the gear, teeth cannot be rigidly inserted into tooth grooves of the gear, tooth crests of the gear are prevented from being damaged, and the processing rhythm of the gear cannot be influenced when a small-modulus gear or a thin gear is met; and when tooth crest chamfers of some products are too large, the racks are correspondingly pushed away, so that collision force is not too large, and tooth crests are prevented from being damaged.

Owner:浙江陀曼智能科技股份有限公司

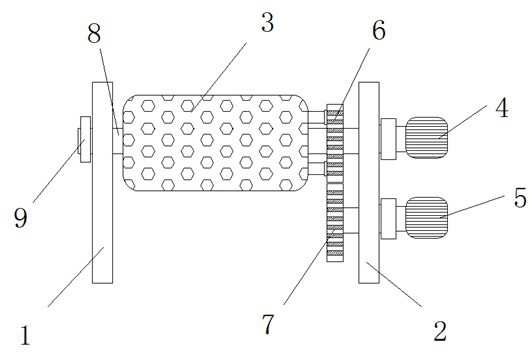

Compressed air filter

The invention discloses a compressed air filter, and belongs to the field of compressed air filtering devices. The compressed air filter comprises a cylinder body. A gas inlet pipe and a gas outlet pipe are arranged on the cylinder body. The gas inlet pipe inclines downwards and backwards to intersect with the wall of the cylinder body so that an included angle can be formed. A spiral diversion groove is formed in the cylinder body. The inlet end of the diversion groove is connected with the gas inlet pipe. The outlet end of the diversion groove is open. A plurality of filter screens are arranged in the cylinder body. The gas inlet pipe is connected with the diversion groove in a tangent mode so that the direction of compressed air entering the gas inlet pipe can be smoothly guided. By fine filtering out water in compressed air in the filter and discharging compressed air, the quality of an air source is prevented from being influenced by too much water in compressed air, pneumatic elements are prevented from being damaged by too much water, basically no electric energy is needed, mechanical loss is little, and no maintenance is needed.

Owner:HUNAN JIUDING TECH (GRP) YONGZHOU DINGLI FEED CO LTD

Production and transportation device for plastic-coated steel pipe

The invention relates to the technical field of plastic-coated steel pipes, and provides a production and transportation device for plastic-coated steel pipes. The production and transportation devicecomprises first side walls, second side walls, a first bottom plate and a second bottom plate; the two side edges of the first bottom plate are both connected with the first side walls, material grooves used for containing the plastic-coated steel pipes are formed and internally provided with shock-proof structures, and the shock-proof structures comprise material-loading plates and anti-collision plates; and first buffer structures are clamped between the first side walls and the second side walls, second buffer structures are clamped between the first bottom plate and the second bottom plate, each second buffer structure comprises a lifting assembly and a sliding assembly which are mutually connected, and the second buffer structures further comprise magnetic block assemblies. In this way, the production and transportation device can well buffer wobbling generated in the transportation process of the plastic-coated steel pipes, collision between the plastic-coated steel pipes is effectively avoided, and the quality of the plastic-coated steel pipes is improved.

Owner:山东共达电力设备有限公司

Long bar feeder

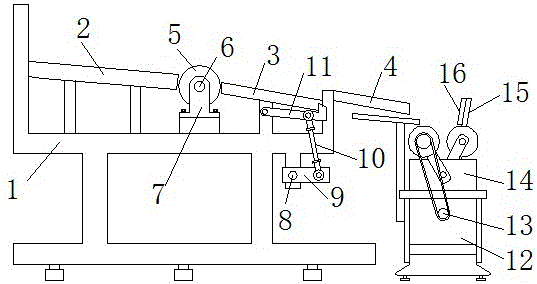

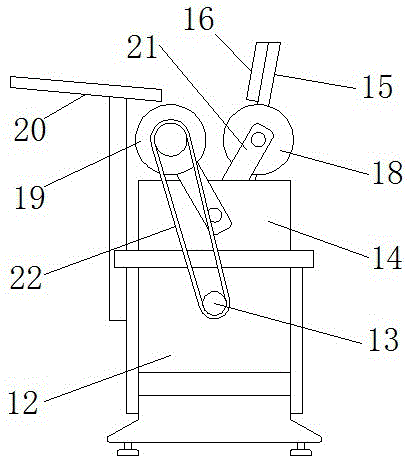

InactiveCN106553895AReduce falling speedReduce kinetic energyConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a long bar feeder. The long bar feeder comprises a frame, wherein a bar storage rack, a conveying rack and a loading rack are successively arranged on the upper part of the frame from left to right in a beveling manner; a drum is arranged between the bar storage rack and the conveying rack; a plurality of projections are arranged on the surface of the drum; a plurality of raising rods, rockers and cranks are arranged below the conveying rack; two ends of each rocker are respectively connected with the corresponding raising rod and the corresponding crank rotatably; the other end of each raising rod is rotatably connected with the frame; the cranks are driven by a first rotating shaft; a conveying mechanism is arranged on the right side of the frame; a plurality of supporting seats which are distributed equidistantly are arranged above the conveying mechanism; a first roll and a second roll which are arrayed in a cross manner in the left-right direction are arranged on the front side and the rear side of each supporting seat; and projected threads are respectively arranged on the surfaces of the first rollers and the second rollers. The long bar feeder has the beneficial effects that completely automated loading can be realized, and the circumstance that a collision force is over large when long bars collide with the conveying mechanism in a dropping process of the long bars is avoided.

Owner:卢文哲

Motor vehicle collision device with differential-pressure stop valve

A motor vehicle collision device with a differential-pressure stop valve comprises at least two piston cylinders, at least two pistons, at least two piston cylinder screw hole connectors, at least four high-pressure connection pipes, at least two switch control energy dampers and a differential-pressure stop valve; the differential-pressure stop valve comprises a stop valve substrate assembly, a stop valve rod assembly, a first T-shaped top plate, a second T-shaped top plate, a first top-plate spring, a second top-plate spring, a first end cover and a second end cover; and when the difference of the hydraulic force applied on an annular area of the first stop valve rod and the second stop valve rod is greater than the advance-applied force of the top plate springs, the pressure connection between the first high-pressure connection pipe and a second high-pressure connection pipe as well as between the third high-pressure connection pipe and the fourth high-pressure connection pipe is disconnected by the stop valve rod assembly, so that a switch valve rod assembly at the early state of the offset collision can be prevented from being forcedly opened in advance, and the offset collision capacity of a motor vehicle can be greatly improved.

Owner:凌建军

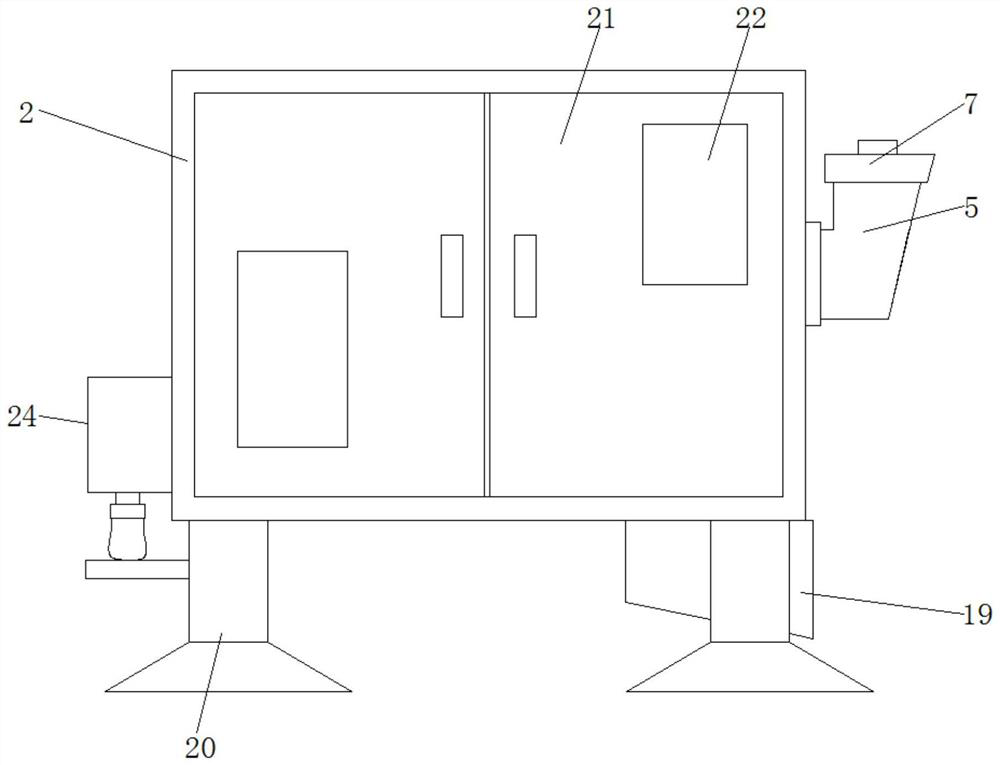

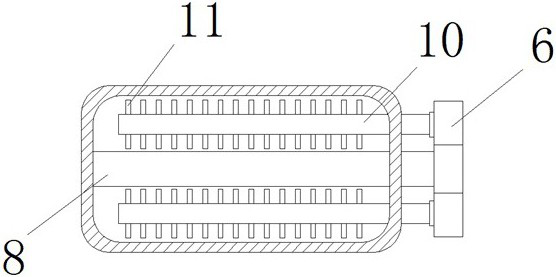

Ball mill capable of continuously processing lithium battery raw materials

PendingCN114130481AEasy to viewHearing protectionCleaning using gasesGrain treatmentsThermodynamicsElectric machine

The ball mill comprises a ball milling barrel, a discharging conveying mechanism, a heat dissipation mechanism and a dust removal mechanism, a supporting shaft is installed on one side of the ball milling barrel and rotationally connected with a protection box through a first bearing, and meanwhile the other side of the ball milling barrel is rotationally connected with a feeding pipe through a second bearing; the ball mill capable of continuously processing the lithium battery raw materials is provided with the heat dissipation mechanism and the dust removal mechanism, through the heat dissipation mechanism, when a first driving motor works, the first driving motor is driven by the heat dissipation mechanism, the first driving motor is driven by the dust removal mechanism, and the first driving motor is driven by the dust removal mechanism to continuously process the lithium battery raw materials. And rapid heat dissipation and cooling can be conducted, the possibility that a first driving motor is damaged due to high temperature is reduced, the working continuity of the first driving motor is guaranteed, dust in the protection box is cleaned through a dust removal mechanism after machining is completed, the cleanliness of the interior of the protection box is improved, and time and labor are saved.

Owner:江苏超聚新能源科技有限公司

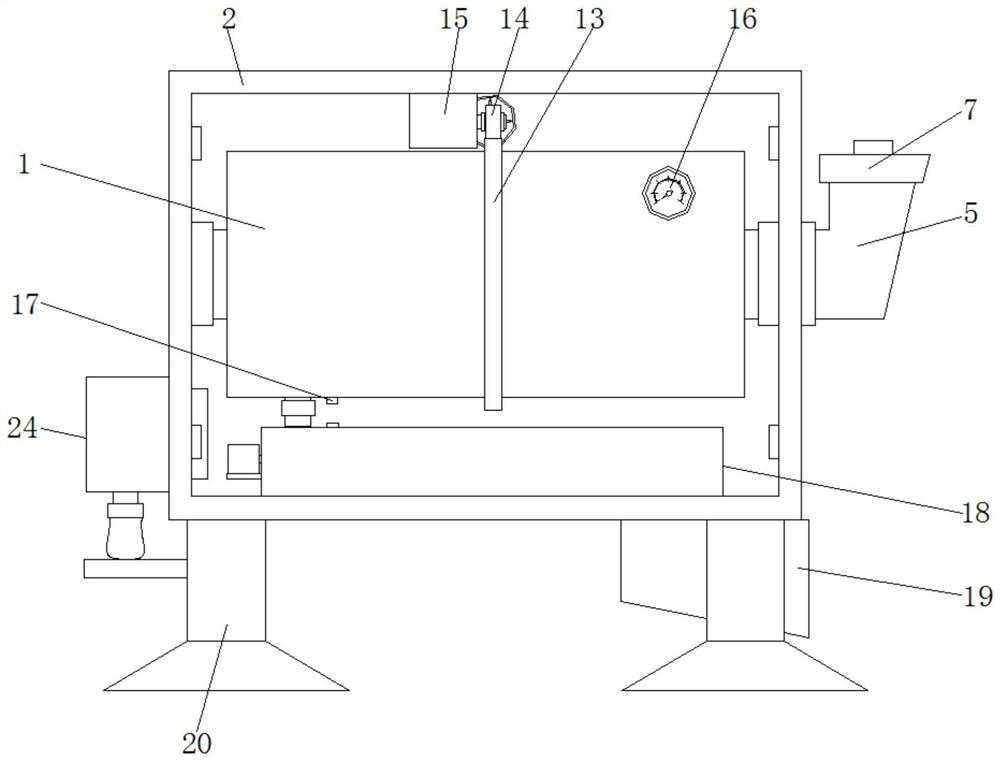

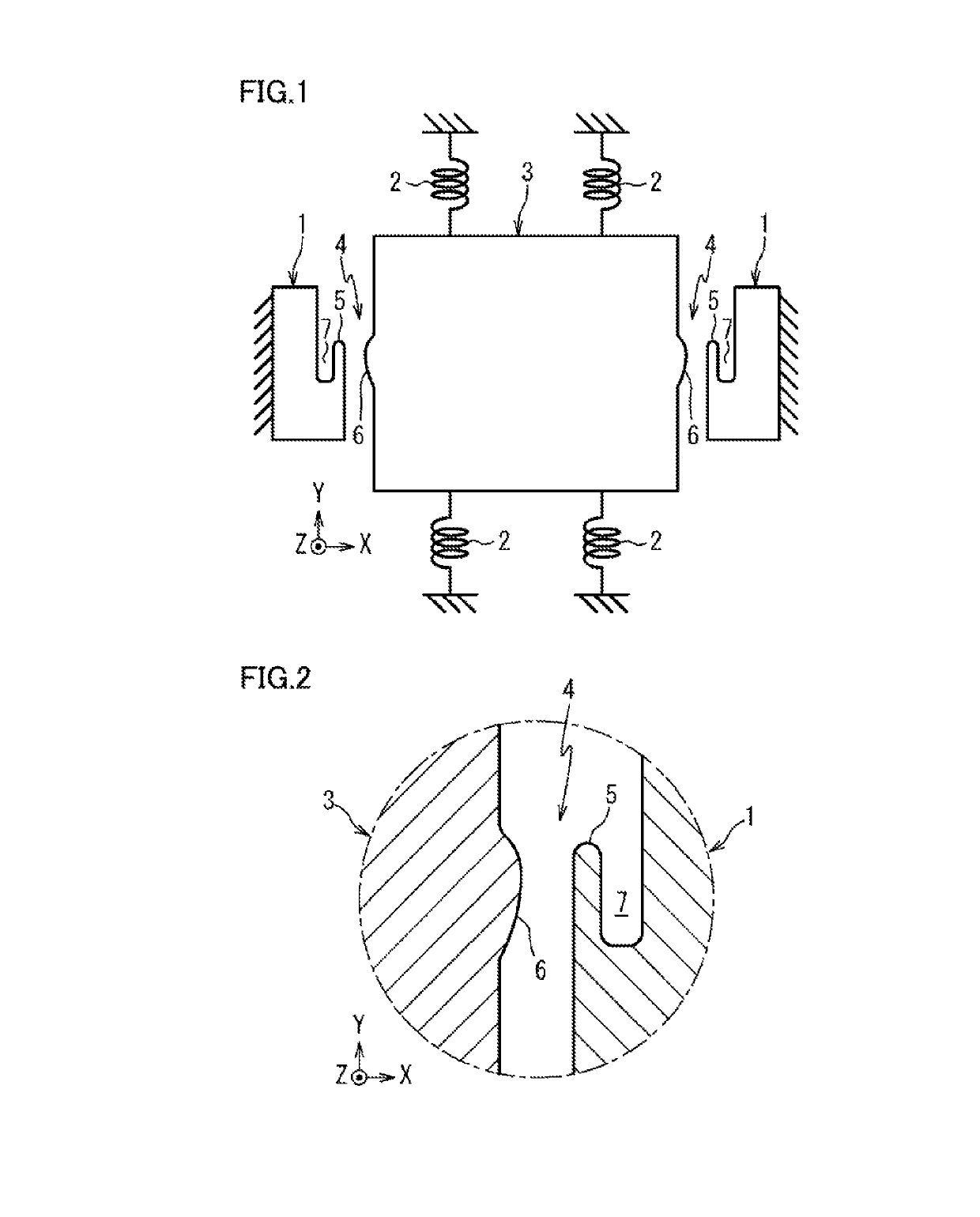

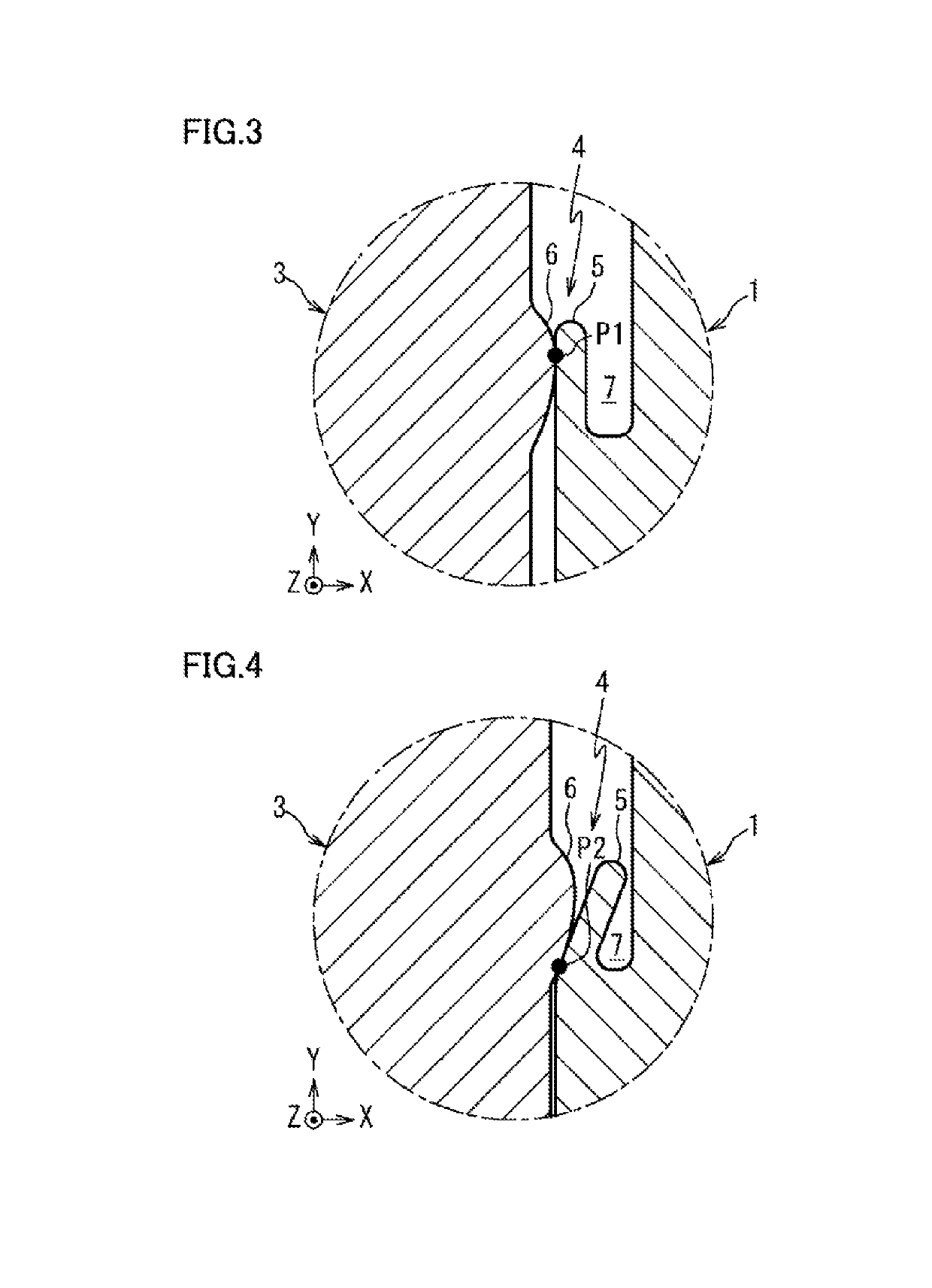

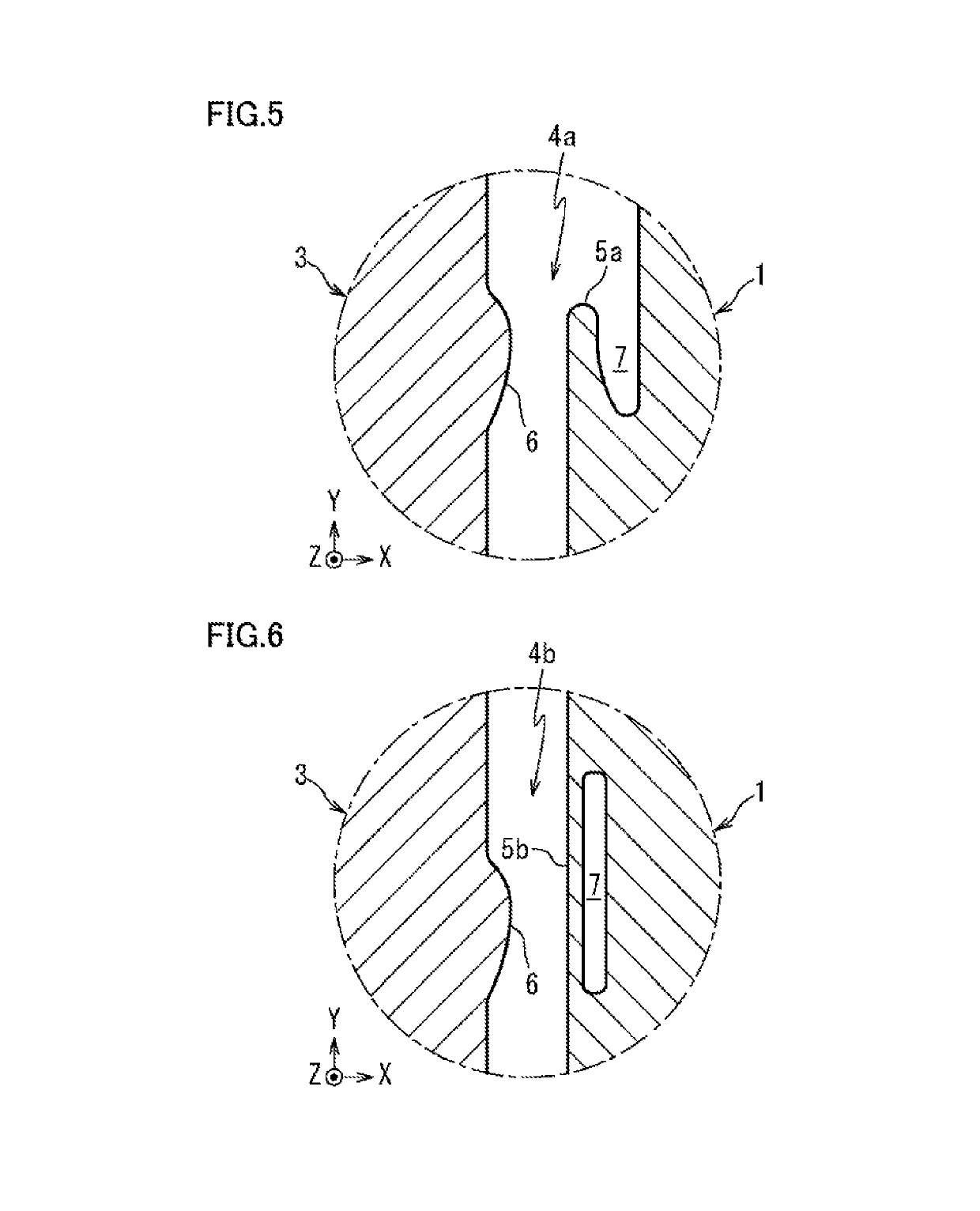

MEMS device

ActiveUS10287159B2Suppress stictionLess likely to be damaged during operationAcceleration measurement using interia forcesDecorative surface effectsElastomerMechanical engineering

A MEMS device including a fixed member and a movable member supported via a resilient body. The MEMS device includes an impact alleviation mechanism provided at a position where the movable member and the fixed member collide during operation. The impact alleviation mechanism includes a stopper provided to either the fixed member or the movable member and that protrude to be parallel between sides of the two members with at least one side edge fixed to the respective member. Moreover, the impact alleviation mechanism includes an elongate protruding member provided on the other of the fixed member and the movable member. The elongate protruding member and the stopper are configured such that as collision force increases between the movable member and the fixed member during operation, an abutment area of an outer edge position of the elongate protruding member approaches the fixed side edge of the stopper.

Owner:MURATA MFG CO LTD

Nut washing apparatus

The invention relates to the field of nut washing equipment, and discloses a nut washing apparatus. The nut washing apparatus comprises a machine body; a motor, a clapboard and a convex part which arearranged inside the machine body; an X-shaped through groove and a gear part are arranged on the clapboard; a rotating disk and a water pump are arranged on the motor; a work bucket is arranged on the rotating disk; a through groove, a sealing rubber sleeve, a rotating shaft, a drum, a brush, a support block, gears, a flute, a through hole and a water tank are arranged on the work bucket; a connector is arranged between the support block and the flute; a liquid injection tube is arranged inside the through hole; a trunk piston, an injection head, a plug and an annular groove are arranged inside the injection tube; a pressure bar is connected onto the trunk piston; a connector is arranged between the pressure bar and an outer wall of the machine body; a first water pipe is connected between the water tank and the liquid injection tube; and a second water pipe is connected between the water tank and the water pump. By adopting the technical scheme, the nut washing apparatus solves the problems of difficult washing on small-size nuts, such as apricot kernels, pine nuts and the like, by using existing nut washing equipment as well as serious resource waste in the prior art.

Owner:象山锦绣升平食品有限公司

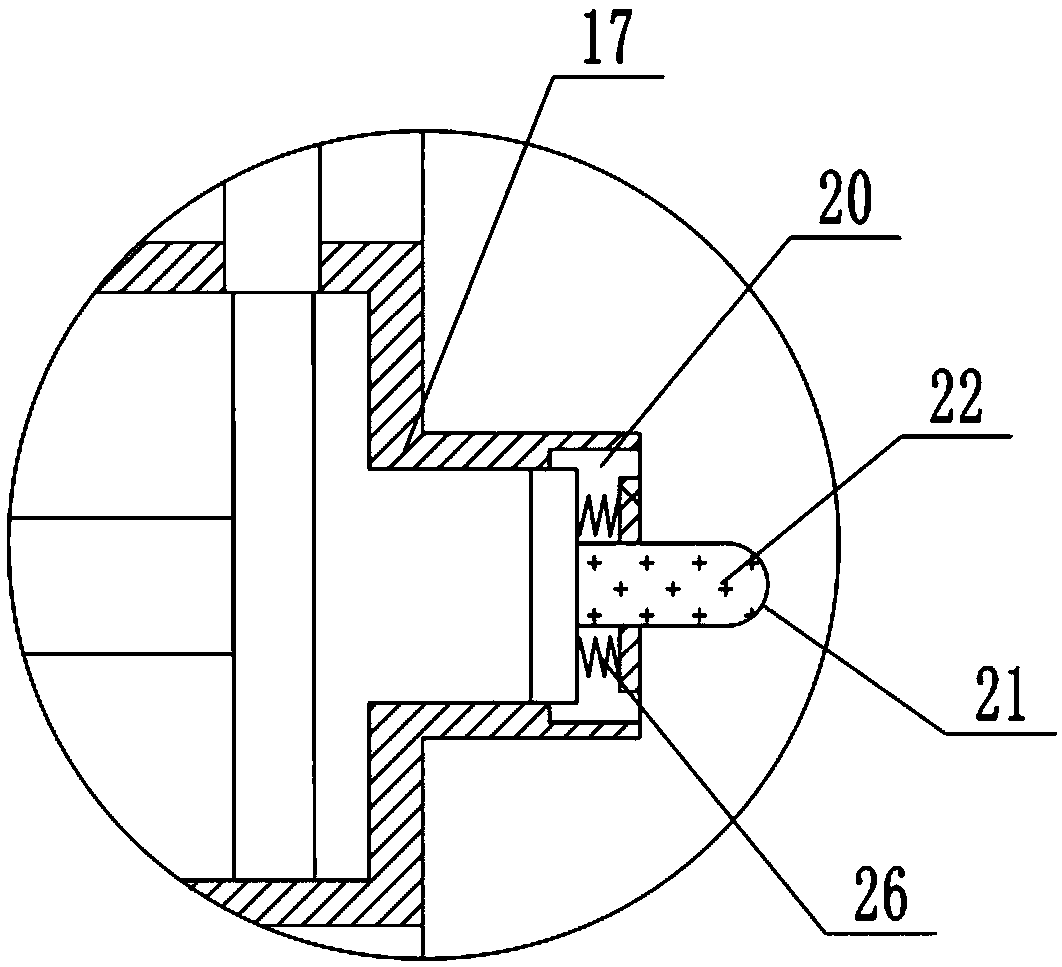

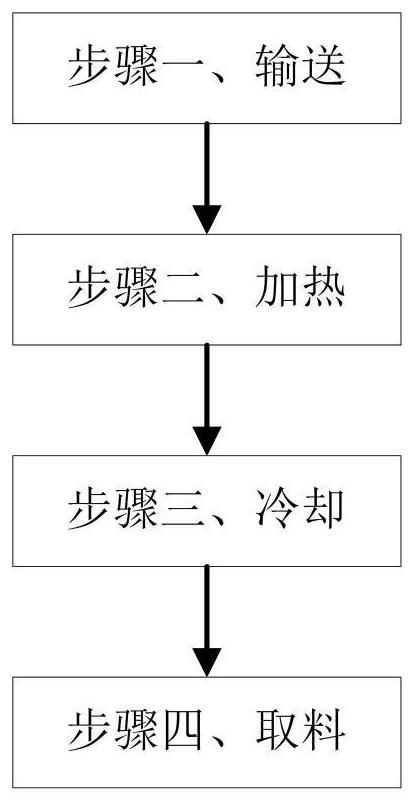

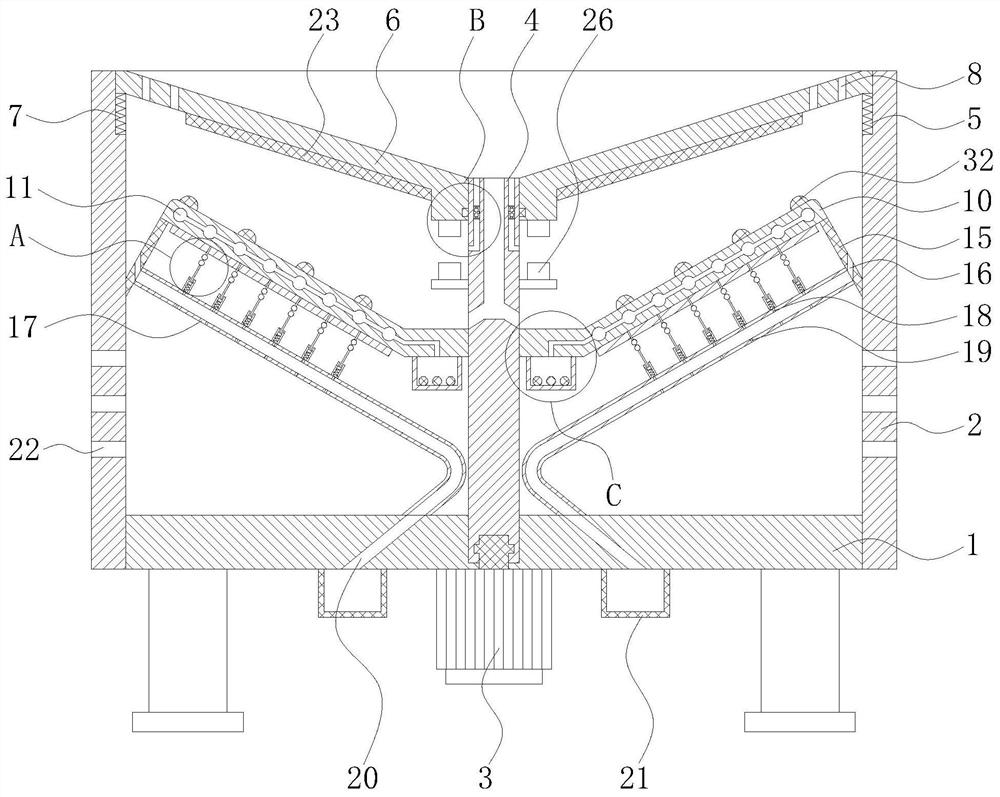

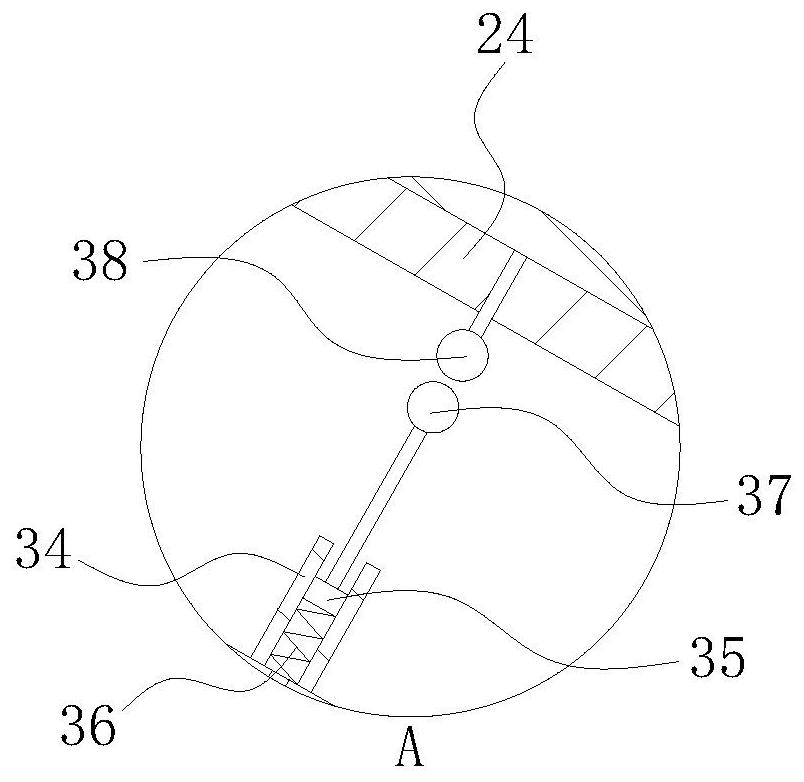

Drying technology for green organic compound fertilizer after granulation forming

PendingCN112815663AAvoid breakageIncrease the collision forceDrying chambers/containersDrying solid materialsThermodynamicsSoil science

The invention belongs to the technical field of fertilizer production, and particularly relates to a drying technology for a green organic compound fertilizer after granulation forming. The technology is completed by adopting a drying device for the green organic compound fertilizer after granulation forming in a cooperative mode, and comprises the following steps that S1, conveying is carried out, and specifically, fertilizer granules on the upper surface of a material containing disc slide to the upper surface of a heating disc from a first falling groove; S2, heating is carried out, wherein a main shaft and the heating disc are driven to rotate through a driving motor, the fertilizer particles on the heating disc slide towards the edge of the heating disc under the action of centrifugal force and absorb heat of the heating disc, and water in the fertilizer particles overflows from an air outlet groove after being evaporated; S3, cooling is carried out, wherein the fertilizer particles enter a material guide pipe through a second material falling groove, and air cools the fertilizer particles and takes away residual moisture on the surfaces of the fertilizer particles at the same time; and S4, material taking is carried out, the fertilizer particles fall into an annular material receiving box, the annular material receiving box is taken down, and the fertilizer particles are poured out. According to the drying technology, when the fertilizer particles are dried, the situation that the fertilizer particles are broken is avoided, and the situation that the fertilizer particles are bonded in the annular material receiving box is avoided.

Owner:张敏

Sprinkler for agricultural seedlings

ActiveCN111512935BIncrease spray water pressureIncrease the collision forceWatering devicesCultivating equipmentsIsosceles trapezoidAgricultural engineering

Owner:广西田东长江天成种苗有限公司

A fully automatic grinding machine for ore mining

ActiveCN112756072BExpand the speed range of useWide GrindingGrain treatmentsMining engineeringMineralogy

The invention relates to the technical field of grinding machine equipment, and discloses a fully automatic grinding machine for ore mining, including a frame and a drum, the inner wall of the drum is connected with a liner through a connecting block, and the liner and the drum A driving bag is arranged between the inner walls, and the driving bag is filled with expansion plastic fluid. The ore mining adopts a fully automatic grinding machine. Through the hinge of the lining plate, when the mineral material is rising, because the side of the lining plate away from the connecting block is lower, the formed slope forms a support for the mineral material, effectively reducing the mineral material. Skidding, and when the mineral material reaches the high point, the lining board will actively separate the mineral material when it is opened, which can ensure the separation of the mineral material from the drum at high speed, expand the operating speed range of the grinding machine, and use the expansion plasticity The instantaneous fluid expansion is approximately fixed to increase the impact force, and at the same time, the force buffer force can be distributed to the whole world, greatly reducing the damage caused by the impact force, and at the same time, the noise generated by the impact will also be greatly reduced.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

Ball-milling crushing equipment for nano-material production and processing

InactiveCN112619800AIncrease the collision forceEasy to crushGrain treatmentsElectric machineryStructural engineering

The invention discloses a nano-material, belongs to the technical field of nano-material production, and discloses ball-milling crushing equipment for nano-material production and processing, which comprises a first support plate; a second support plate is arranged on one side far away from the first support plate; a crushing box arranged between the first support plate and the second support plate; a rotating rod is movably connected between the first support plate and the second support plate, penetrates through a crushing box in a penetrating mode and is fixedly connected with the crushing box; and a first motor is fixedly connected to the side, away from the first support plate, of the second support plate. The ball-milling crushing equipment for the nano-material production and processing provided by the invention has the following beneficial effects: different from traditional crushing equipment, the crushing box rotates clockwise and stirring rods rotate counterclockwise, which make the collision force of nanomaterials greater and the nanomaterials are easily stirred and crushed; and meanwhile, the inner wall of a crushing cavity in the crushing box consists of a plurality of prismatic edges, so that the roughness of the inner wall is increased, the crushing is facilitated, four stirring rods are arranged for stirring, the uniform crushing is facilitated, the overall structure is reasonable, the operation is simple, the use is convenient, the production efficiency and the production quality are improved, and the like.

Owner:徐州世维材料科技有限公司

Automotive vehicle collision device with novel switch type jetting energy dissipater

InactiveCN102463946AAvoid wire contact stress injuriesAvoid friction and strainBumpersHigh pressurePressure difference

The invention discloses an automotive vehicle collision device with a novel switch type jetting energy dissipater, which comprises a piston cylinder, a screw hole joint, a high pressure connection tube and the novel switch type jetting energy dissipater, wherein the novel switch type jetting energy dissipater comprises a high pressure buffer chamber, a low pressure buffer chamber, a pedestal jetting hole, an upper part valve cylinder, a middle part valve cylinder, a lower part valve cylinder, an upper part shuttle valve, a middle part shuttle valve and a lower part shuttle valve; the pedestal jetting hole penetrates from the middle part valve cylinder to the low pressure buffer chamber; a liquid channel is arranged between the middle part valve cylinder and the middle part shuttle valve; a liquid channel is arranged between the lower part valve cylinder and the lower part shuttle valve; and each shuttle valve assembly can vertically shuttle according to a pressure difference between the upper end and the lower end, so that the corresponding liquid channel between the lower part valve cylinder and the lower part shuttle valve is closed. According to the automotive vehicle collision device with the novel switch type jetting energy dissipater, the contact strain problem and the loss problem of wires between the shuttle valve and the valve cylinder can be solved, the automotive vehicle can be ensured to have a bidirectional anti-collision function, and the automotive vehicle body can be ensured to be always in a stretching state.

Owner:凌建军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com