Vertical shaft impact type crusher

A vertical shaft impact and crusher technology, applied in the field of mining equipment, can solve the problems of poor crushing effect, poor rebound effect, and difficulty in refining the stone, achieving good wear resistance, avoiding repeated crushing, and fast discharging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

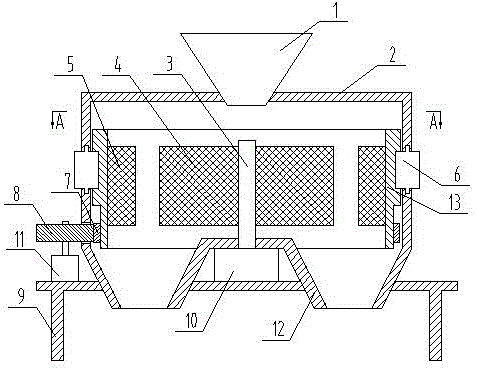

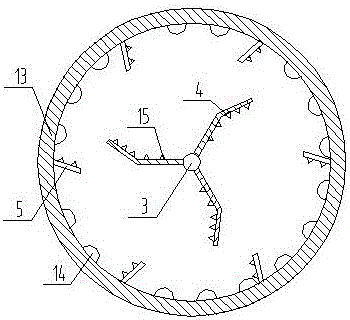

[0026] Such as Figure 1 to Figure 2 As shown, a vertical shaft impact crusher includes a feed hopper 1, a body 2, a rotating shaft 3, a frame 9, a positive rotation motor 10 and a discharge hopper 12, the upper end of the body 2 is provided with a feed hopper 1, and the The lower end of the body 2 is provided with a discharge hopper 12, and the discharge hopper 12 is assembled on the frame 9, and the forward rotation motor 10 is arranged on the frame 9, and the forward rotation motor 10 is connected with one end of the rotating shaft 3, and the rotating shaft 3 The other end of the body 2 passes through the bottom wall of the body 2 and is arranged in the inner cavity of the body 2, and the positive rotation ribs 4 are evenly arranged. The shaft 6, the roller 6 and the cylinder 13 are assembled together, the inner wall of the cylinder 13 is uniformly arranged with reverse ribs 5, and the outer wall of the cylinder 13 is equipped with a ring gear 7, so Said frame 9 is also pr...

Embodiment 2

[0029] Such as Figure 1 to Figure 2 As shown, a vertical shaft impact crusher includes a feed hopper 1, a body 2, a rotating shaft 3, a frame 9, a positive rotation motor 10 and a discharge hopper 12, the upper end of the body 2 is provided with a feed hopper 1, and the The lower end of the body 2 is provided with a discharge hopper 12, and the discharge hopper 12 is assembled on the frame 9, and the forward rotation motor 10 is arranged on the frame 9, and the forward rotation motor 10 is connected with one end of the rotating shaft 3, and the rotating shaft 3 The other end of the body 2 passes through the bottom wall of the body 2 and is arranged in the inner cavity of the body 2, and the positive rotation ribs 4 are evenly arranged. The shaft 6, the roller 6 and the cylinder 13 are assembled together, the inner wall of the cylinder 13 is uniformly arranged with reverse ribs 5, and the outer wall of the cylinder 13 is equipped with a ring gear 7, so Said frame 9 is also pr...

Embodiment 3

[0036] Such as Figure 1 to Figure 2 As shown, a vertical shaft impact crusher includes a feed hopper 1, a body 2, a rotating shaft 3, a frame 9, a positive rotation motor 10 and a discharge hopper 12, the upper end of the body 2 is provided with a feed hopper 1, and the The lower end of the body 2 is provided with a discharge hopper 12, and the discharge hopper 12 is assembled on the frame 9, and the forward rotation motor 10 is arranged on the frame 9, and the forward rotation motor 10 is connected with one end of the rotating shaft 3, and the rotating shaft 3 The other end of the body 2 passes through the bottom wall of the body 2 and is arranged in the inner cavity of the body 2, and the positive rotation ribs 4 are evenly arranged. The shaft 6, the roller 6 and the cylinder 13 are assembled together, the inner wall of the cylinder 13 is uniformly arranged with reverse ribs 5, and the outer wall of the cylinder 13 is equipped with a ring gear 7, so Said frame 9 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com