Motor vehicle collision device with jet energy consumer

A technology of collision device and energy dissipator, which is applied to bumpers and other directions, can solve problems such as extrusion deformation of motor vehicle body, unfavorable personnel protection, and reduction of piston cylinder length, so as to reduce rollover and tail swing accidents, and reduce injuries or deaths. , the effect of reducing the number of injection holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

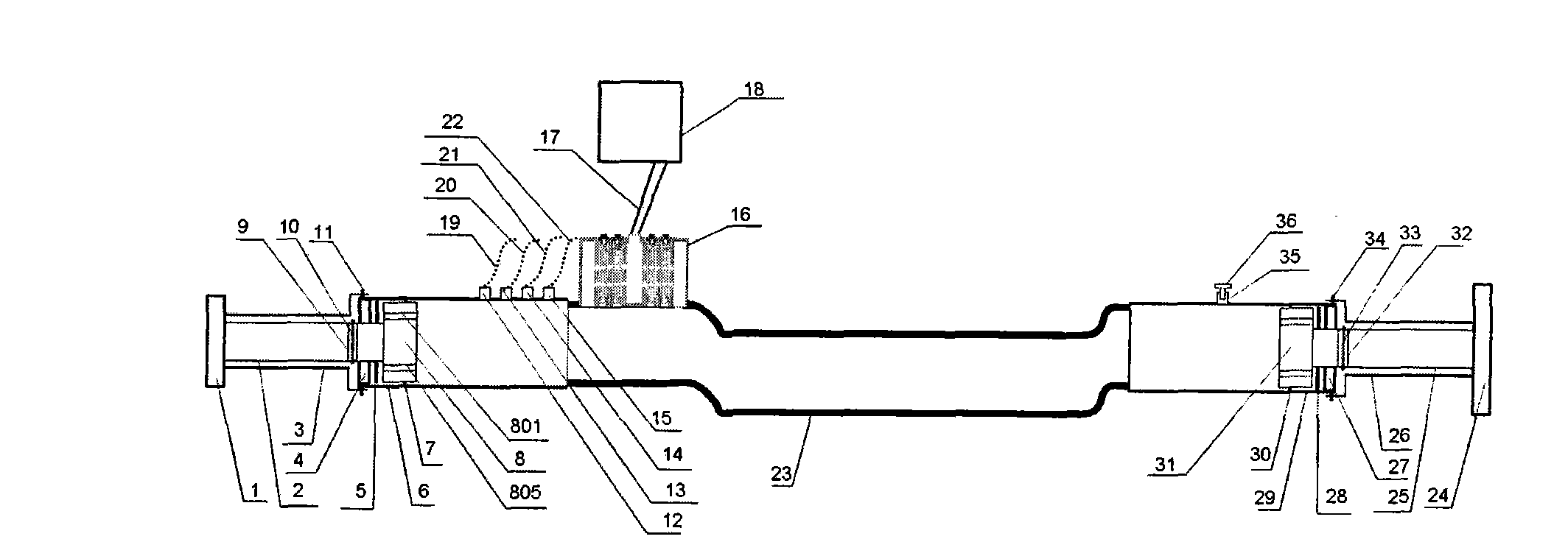

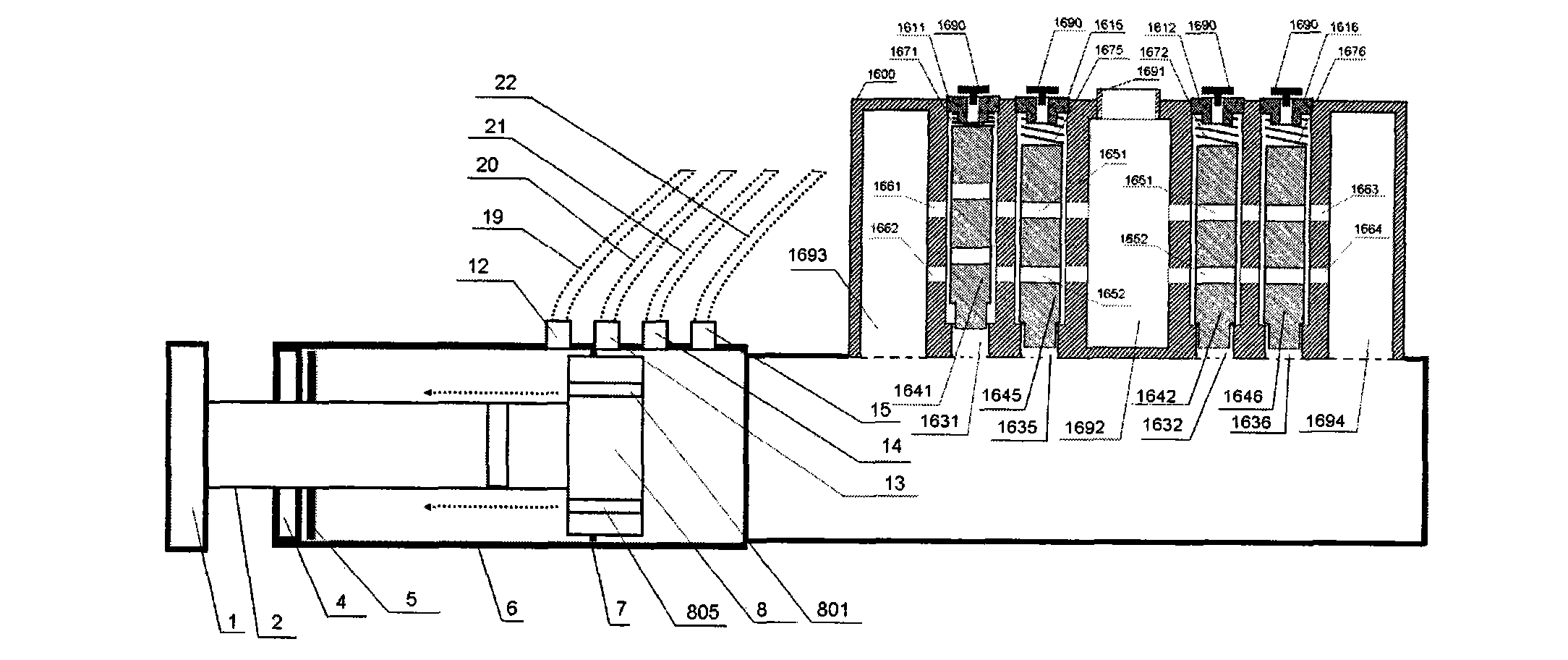

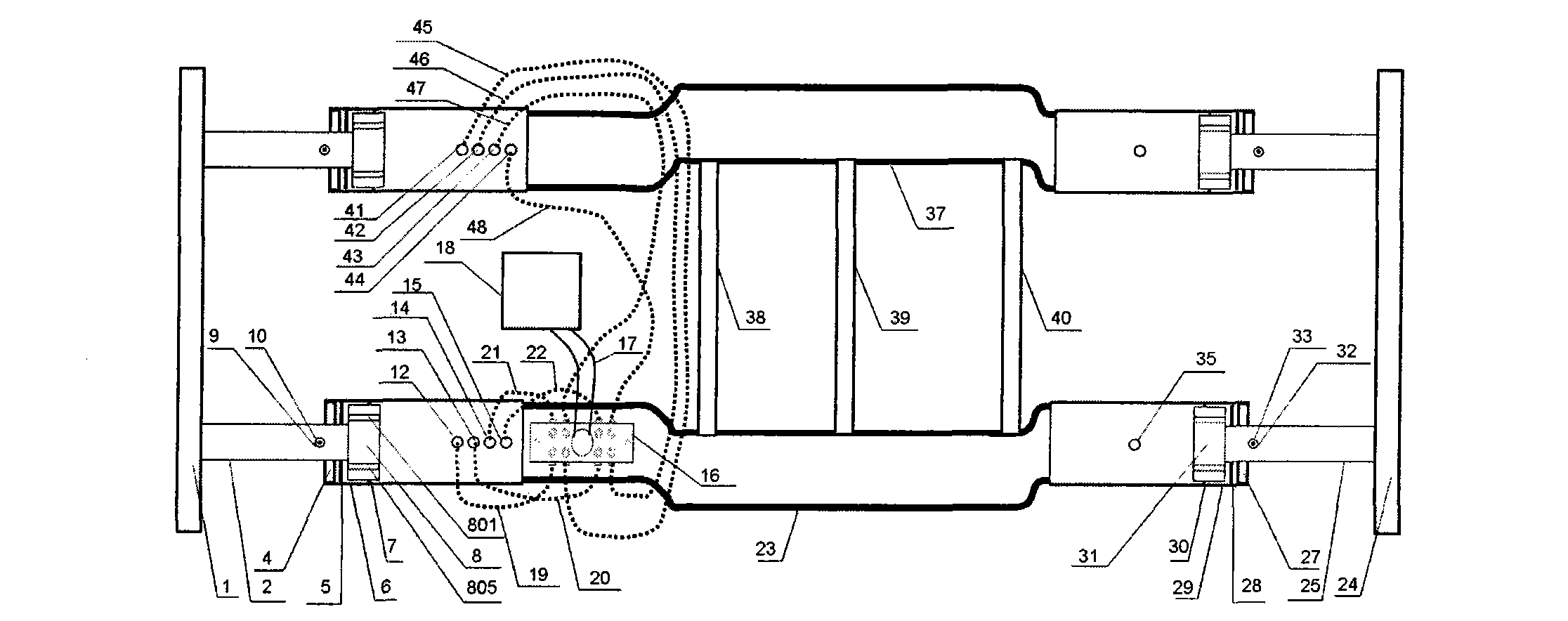

[0049] Such as Figure 1 to Figure 15As shown, the motor vehicle collision device with jet energy consumption device of the present invention comprises a first collision rod 1, a first piston push rod 2, a first preload sleeve 3, a first piston cylinder end cover 4, a first piston injection Hole seal washer 5, first piston cylinder 6, first piston seal ring 7, first piston 8, first pin hole 9, first pin 10, first fixing screw 11, first screw joint 12, second screw Hole joint 13, third screw joint 14, fourth screw joint 15, jet energy consumer 16, low pressure connecting pipe 17, antifreeze buffer box 18, first tubular longitudinal beam 23, second collision bar 24, The second piston push rod 25, the second pre-tensioning sleeve 26, the second piston cylinder end cover 27, the second piston injection hole sealing gasket 28, the second piston cylinder 29, the second piston sealing ring 30, the second piston 31, The second pin hole 32, the second pin 33, the second fixing screw 3...

no. 2 approach

[0084] Figure 17 It is a cross-sectional view of the second embodiment of the motor vehicle collision device with jet energy consumer in the present invention; Figure 18 It is a schematic diagram of the installation and connection of the second embodiment of the motor vehicle collision device with jet energy consumer in the present invention; Figure 19 It is a cross-sectional view of the differential pressure three-way valve of the motor vehicle collision device with jet energy consumer in the present invention.

[0085] The second embodiment is basically the same as the first embodiment, except that four valve cylinders, four valve cylinder end covers, four shuttle valves, four springs, four bolts with holes, four threaded holes, and four positioning valves are removed. Pin, four plugs. Including removing the fifth valve cylinder 1635, the sixth valve cylinder 1636, the seventh valve cylinder 1637, and the eighth valve cylinder 1638; the fifth valve cylinder end cover 16...

no. 3 approach

[0092] Figure 20 It is a cross-sectional view of the third embodiment of the motor vehicle collision device with jet energy consumer of the present invention; Figure 21 It is a schematic diagram of the installation and connection of the third embodiment of the motor vehicle collision device with jet energy consumer according to the present invention.

[0093] The third embodiment is basically the same as the first embodiment, except that four valve cylinders, four valve cylinder end covers, four shuttle valves, four springs, four bolts with holes, four threaded holes, and four positioning valves are removed. Pin, four plugs. Including removing the second valve cylinder 1632, the fourth valve cylinder 1634, the sixth valve cylinder 1636, and the eighth valve cylinder 1638; the second valve cylinder end cover 1612, the fourth valve cylinder end cover 1614, and the sixth valve cylinder end cover 1616 , the eighth valve cylinder end cover 1618; the second shuttle valve 1642, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com