Power car collision device of belt pipe wall type jet energy dissipator

A technology of collision device and energy dissipator, which is applied to bumpers and other directions, can solve problems such as extrusion deformation of motor vehicle body, unfavorable personnel protection, and reduction of piston cylinder length, so as to reduce rollover and tail swing accidents, and reduce injuries or deaths. , the effect of reducing the number of injection holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

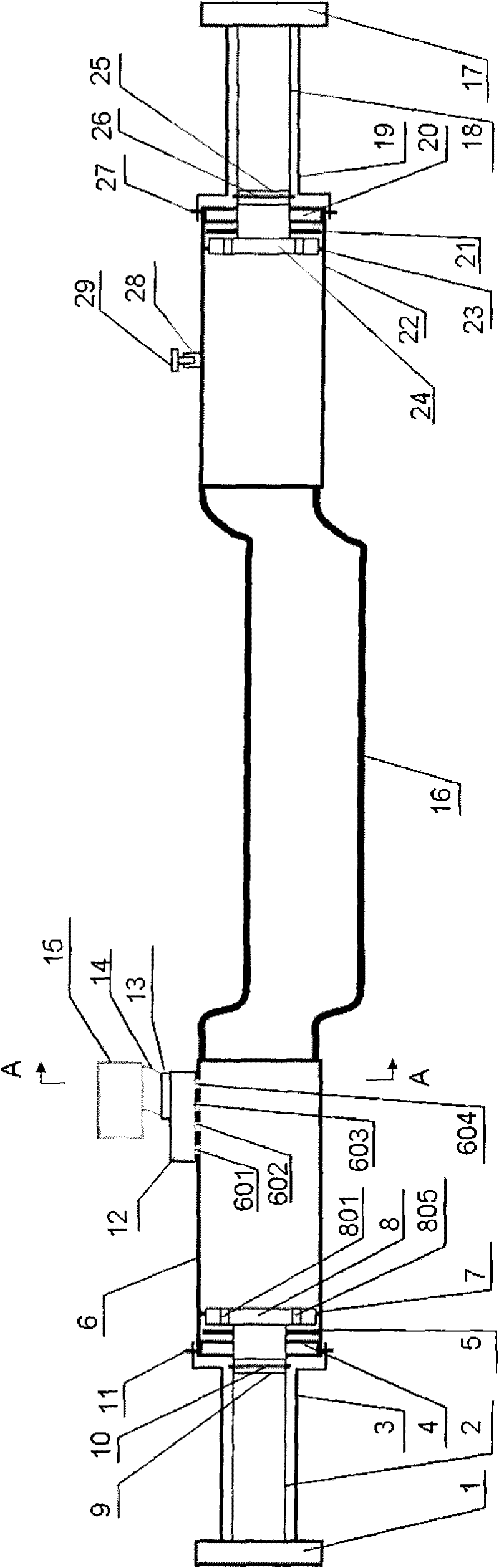

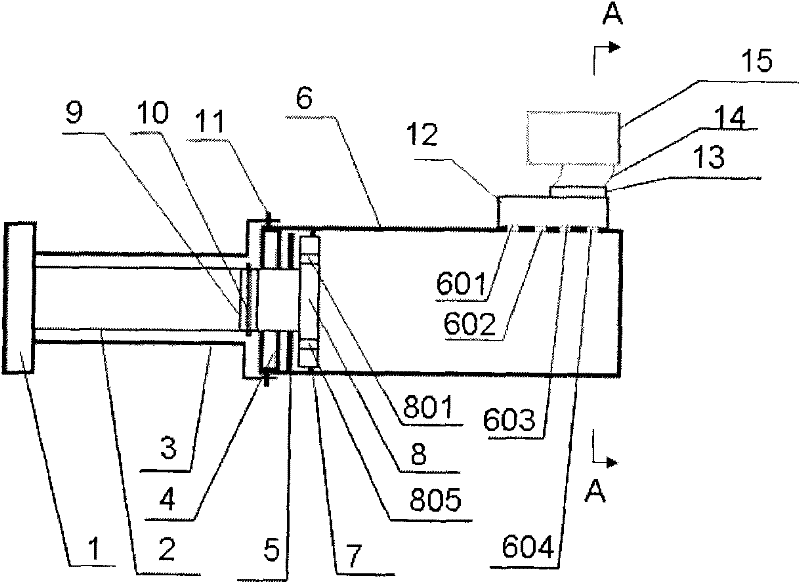

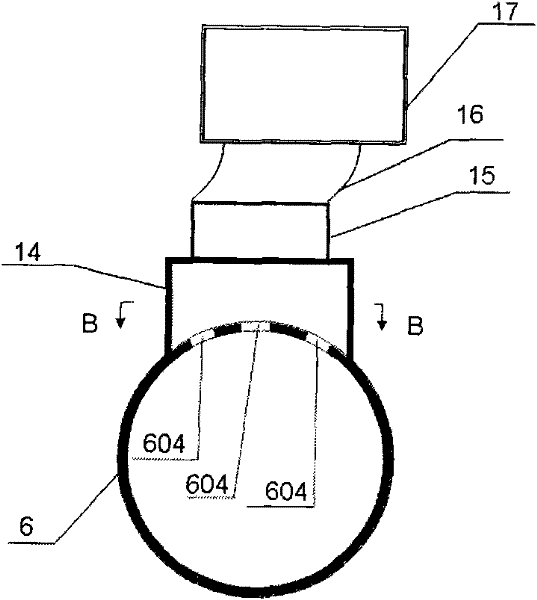

[0044] figure 1 It is an installation schematic diagram of a motor vehicle collision device with a pipe wall type jet energy consumer of the present invention; figure 2 It is a schematic cross-sectional view of a motor vehicle collision device with a wall-type jet energy consumer of the present invention; image 3 It is a schematic cross-sectional view of plane A-A of a motor vehicle collision device with a wall-type jet energy consumer of the present invention; Figure 4 It is a schematic cross-sectional view of B-B plane of a motor vehicle collision device with a pipe wall type jet energy consumer of the present invention; Figure 5 It is a schematic cross-sectional view of the double piston and the piston ejector rod; Figure 6 It is a schematic diagram of the left view of the double piston and the piston ejector rod; Figure 7 It is a top view schematic diagram of the connection of a motor vehicle collision device with a pipe wall type jet energy consumer according to ...

no. 2 approach

[0072] Figure 11 It is a cross-sectional view of the second embodiment of a motor vehicle collision device with a wall-type jet energy consumer of the present invention; Figure 12 It is a schematic diagram of the installation and connection of the second embodiment of a motor vehicle collision device with a pipe wall jet energy consumer of the present invention. The second embodiment is basically the same as the first embodiment: on the basis of the first embodiment, the low-pressure connecting pipe 14 and the antifreeze box 15 are removed, and a drain pipe sealing plug 34 is newly added; the drain pipe sealing plug 34 is installed on the discharge pipe 13. When a collision occurs, the pressure in the spray buffer chamber 12 will increase rapidly, the drain pipe sealing plug 34 will be destroyed, and the antifreeze will be sprayed into the air.

no. 3 approach

[0074] Figure 13 It is a schematic diagram of the third embodiment of a motor vehicle collision device with a pipe wall type jet energy consumer according to the present invention; Figure 14 It is a cross-sectional view of the third embodiment of a motor vehicle collision device with a pipe-wall jet energy consumer according to the present invention.

[0075] The third embodiment is basically the same as the first embodiment: the only difference is that the injection buffer chamber 12 has changed the shape of a cylinder, and correspondingly all the pipe wall injection holes are distributed around the first piston cylinder 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com