Motor vehicle collision device with differential-pressure stop valve

A technology of collision device and cut-off valve, which is applied in the direction of bumpers, etc., can solve the problems of poor anti-rear collision performance, anti-frontal collision performance, failure to reach the collision curve, and inability to absorb kinetic energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

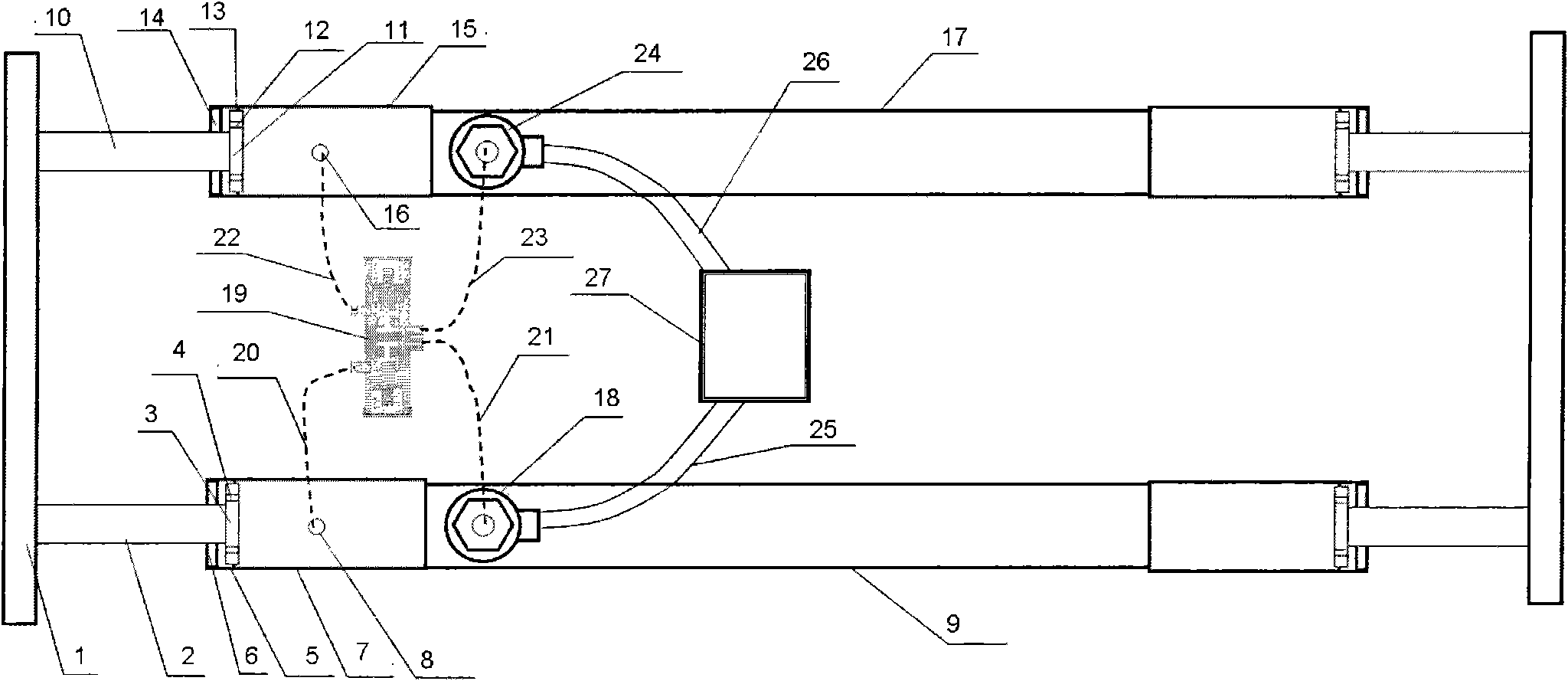

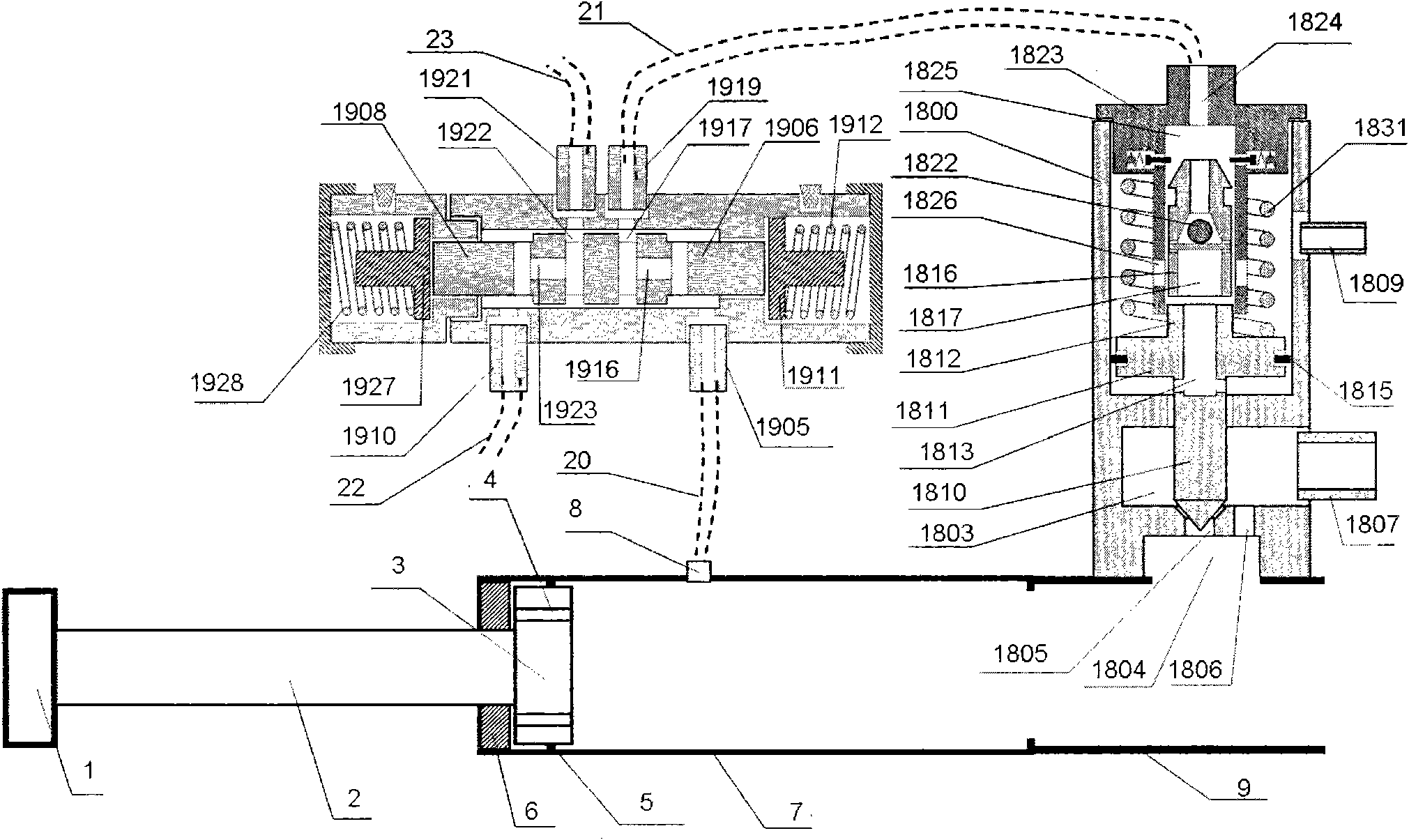

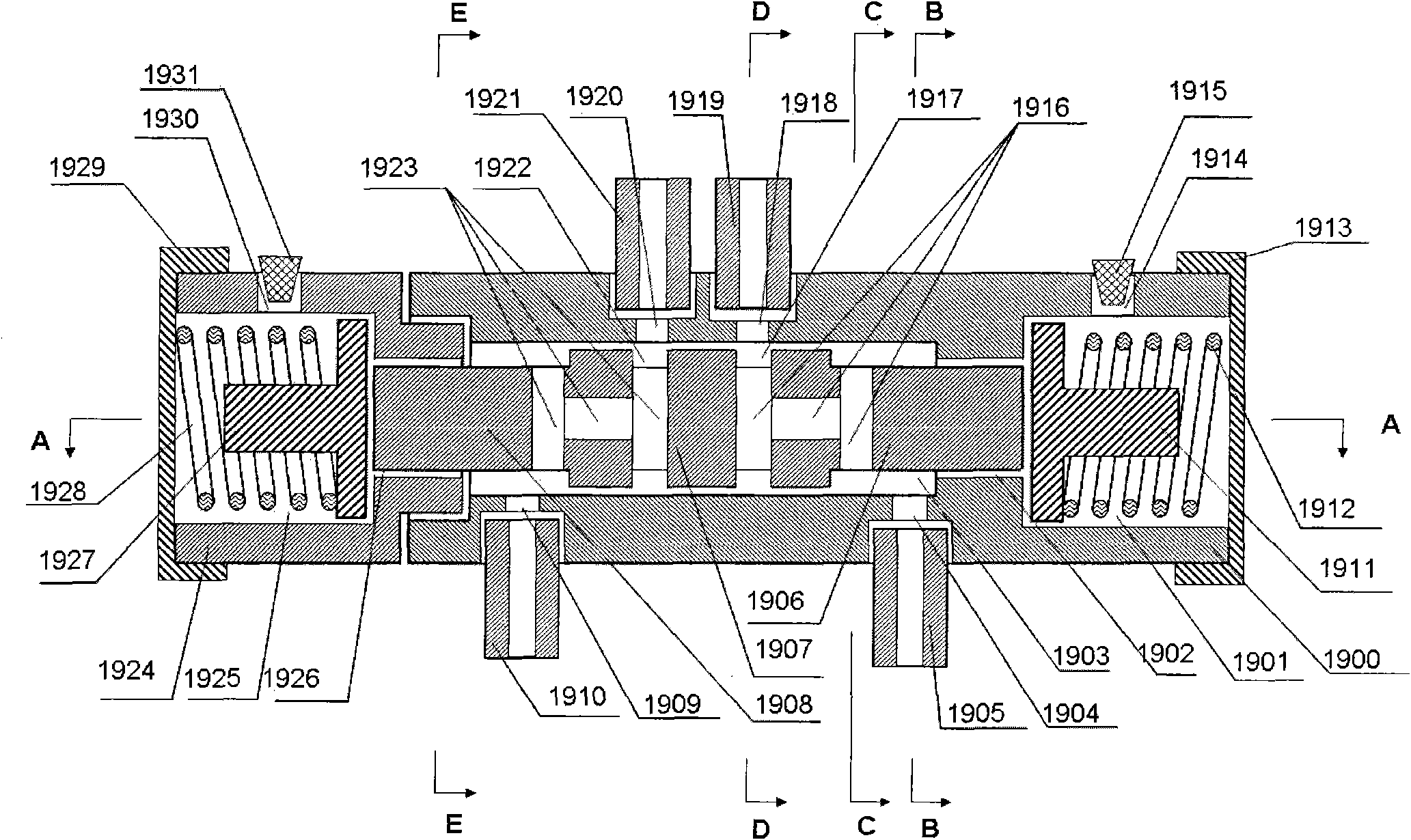

[0048] figure 1 It is a top view schematic diagram of a motor vehicle collision device with a differential pressure shut-off valve of the present invention; figure 2 It is a partial cross-sectional schematic diagram of a motor vehicle collision device with a differential pressure shut-off valve of the present invention; image 3 is a schematic cross-sectional view of a differential pressure stop valve; Figure 4 It is a schematic cross-sectional view of the A-A plane of the differential pressure stop valve; Figure 5 It is a schematic cross-sectional view of the B-B plane of the differential pressure stop valve; Figure 6 It is a schematic cross-sectional view of the C-C plane of the differential pressure stop valve; Figure 7 It is a schematic cross-sectional diagram of the D-D plane of the differential pressure stop valve; Figure 8 It is a schematic cross-sectional view of the E-E plane of the differential pressure stop valve; Figure 9 is a cutaway view of the switc...

no. 2 approach

[0063] Figure 17 It is a schematic cross-sectional view of the second embodiment of the differential pressure stop valve; the principle of the second embodiment is basically the same as that of the first embodiment, the only difference is that an opening sealing nipple 1934 is added; the sealing nipple with holes is added 1934 is between the first shut-off valve seat 1900 and the second shut-off valve seat 1924 .

no. 3 approach

[0065] Figure 18 It is a schematic cross-sectional view of the third embodiment of the differential pressure cut-off valve; the principle of the third embodiment is basically the same as that of the first embodiment, the only difference is that there is a first cut-off valve stem seal on the right section of the cut-off valve stem 1906 Ring groove 1935; there is a second cut-off valve stem seal ring groove 1937 in the left cut-off valve stem 1908; the first cut-off valve stem seal ring groove 1935 and the second stop valve stem seal ring groove 1937 Installed with sealing rings (1936, 1938).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com