Brewing technology of Maotai-flavour Baijiu

A sauce-flavored liquor and process technology, applied in the preparation of alcoholic beverages, methods based on microorganisms, microorganisms, etc., can solve the problems of late-stage product impact, and achieve the effects of small external conditions, easy collection, and soft wine taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below by means of specific embodiments:

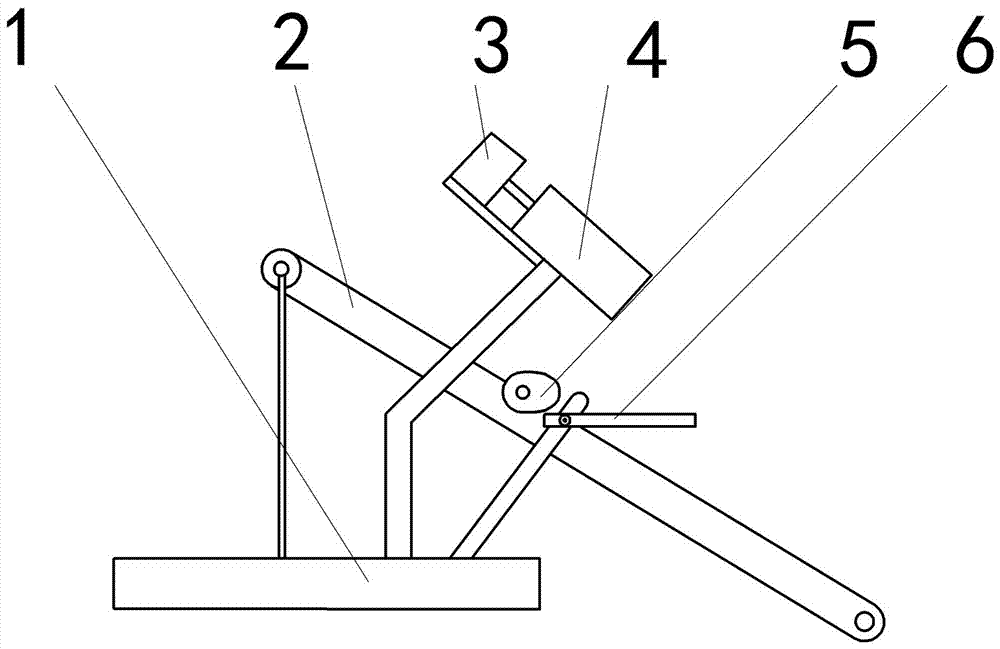

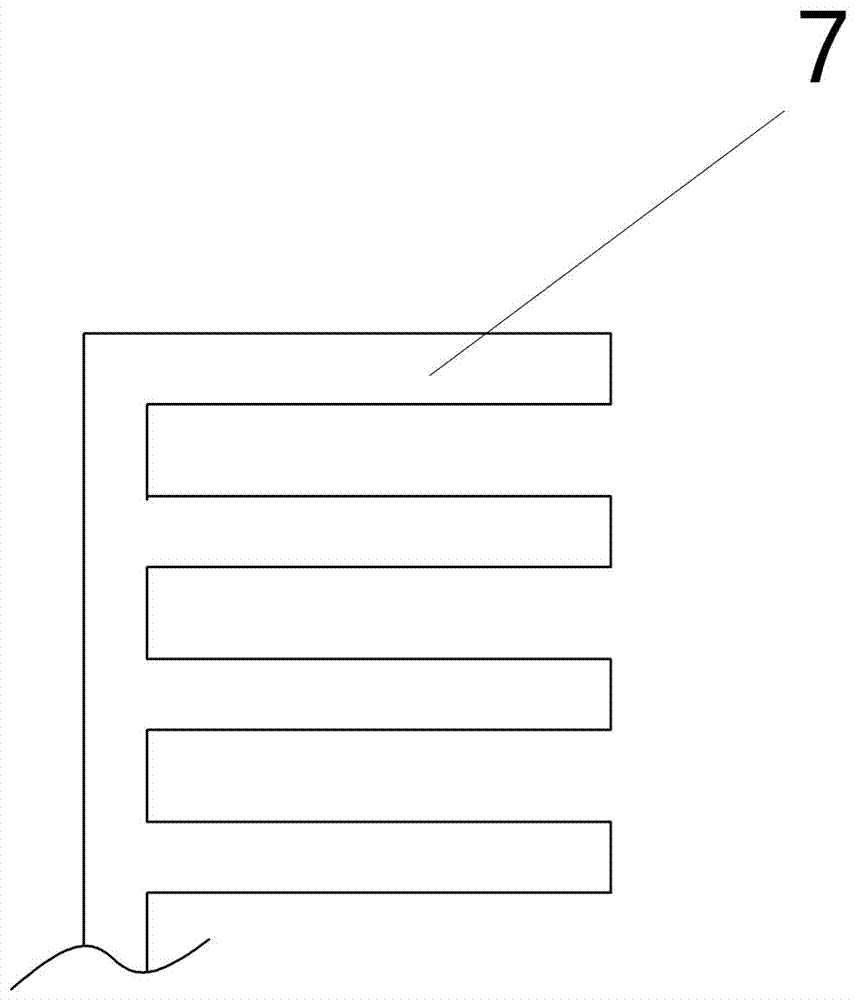

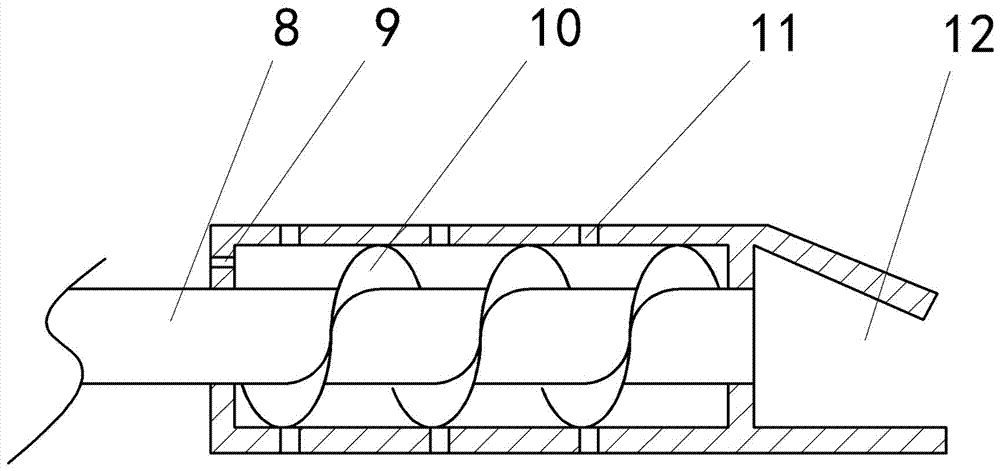

[0034] The reference signs in the drawings of the description include: bracket 1, conveyor belt 2, second motor 3, outer cylinder 4, eccentric wheel 5, lifting plate 6, screening rod 7, rotating shaft 8, air outlet 9, spiral blade 10, Jet hole 11, suction hole 12.

[0035] Embodiment: During the production period of this embodiment, the room temperature was 7-25° C., and three cycles of continuous production were carried out. A brewing process of Maotai-flavor liquor, each production cycle of which comprises the following steps:

[0036] 1) Raw material crushing: including sorghum crushing and high-temperature Daqu crushing;

[0037] 2) Steaming of auxiliary materials: steam the chaff, spread it out to room temperature, and store it in piles after drying;

[0038] 3) Hot water to moisten the grain: Use hot water above 90°C to moisten the grain, and the amount of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com