Metering method and device for fuel coal of boiler

A metering device and coal-burning technology, applied in the direction of measurement device, combustion method, and fuel supply regulation, can solve problems such as poor reliability and practicability, inaccurate metering, distortion or fracture, and ensure stability and accuracy. , to ensure accuracy, to avoid the effect of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

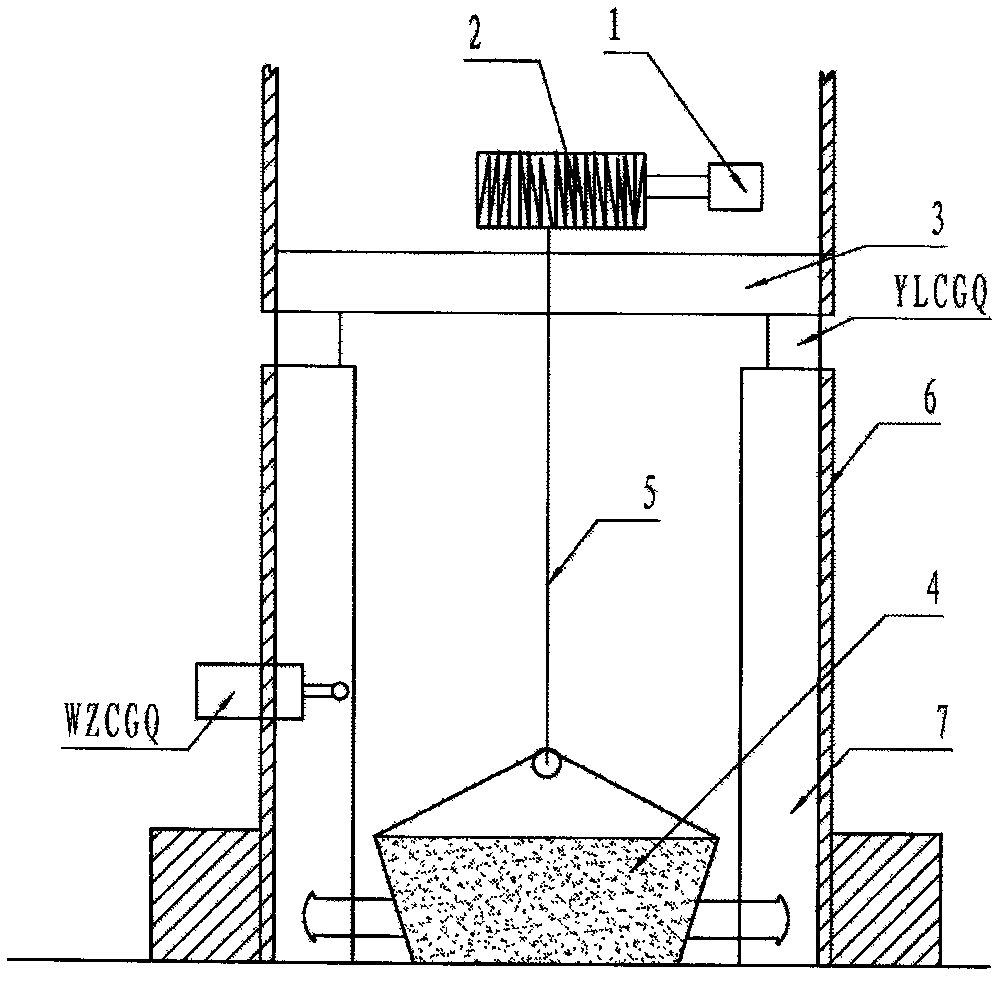

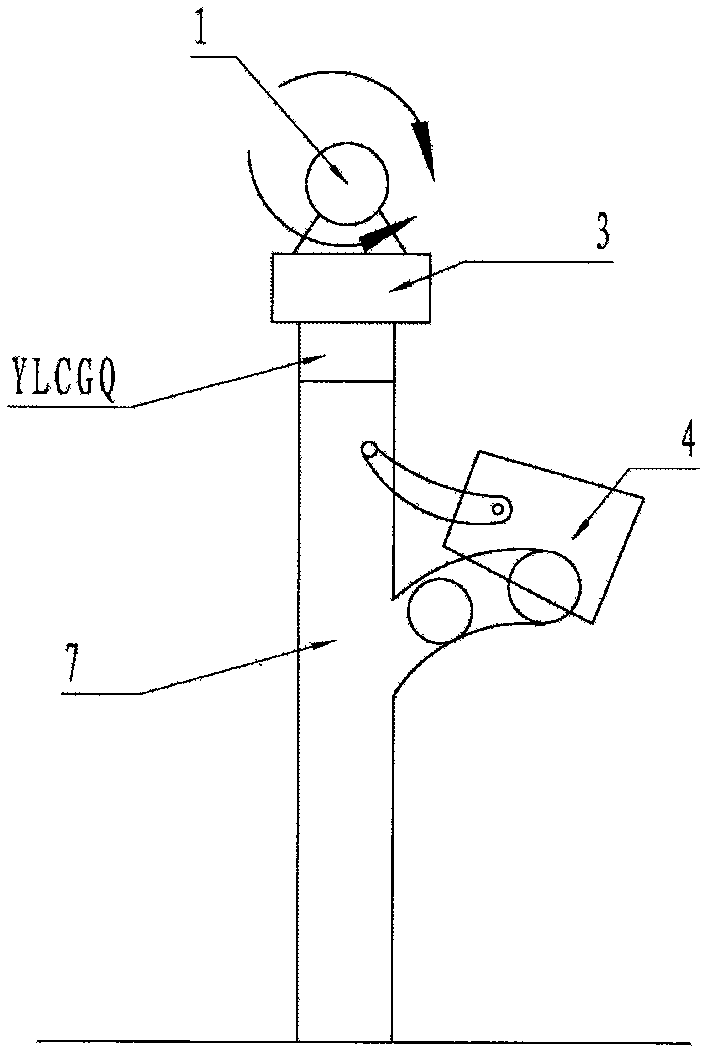

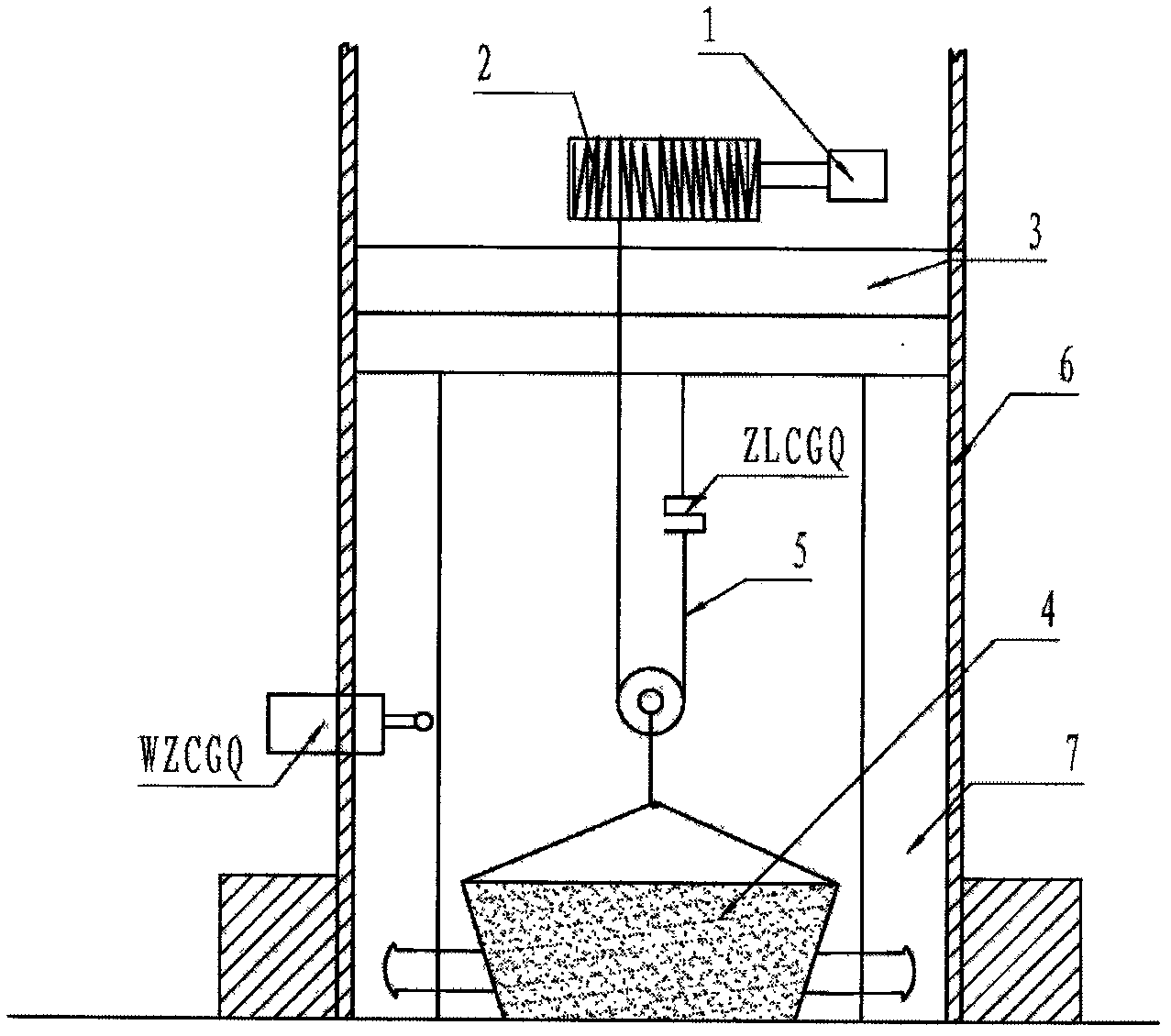

[0027] Below with accompanying drawing as embodiment the present invention is further described: as figure 1 , 2 As shown, the coal-fired metering device of the boiler includes an overturned coal hopper 4, a slideway support 6 matched with the overturned coal hopper 4, a coal hopper hoist, a weighing sensor and a coal counting controller, a coal hopper lifting sensor SJCGQ, a position Sensor WZCGQ. Said hoist is made up of frame 3 and driving motor 1 assembled on frame 3, winding shaft 2 connected with the output of driving motor 1 and lifting rope 5 wound on winding shaft 2. Rope 5 is connected with coal bucket 4. The load cell is a pressure sensor YLCGQ, and the pressure sensor YLCGQ is installed between the frame 3 and the support 6 of the hoist; the output of the pressure sensor YLCGQ is connected to the input end of the programmable controller PLC. The position sensor WZCGQ is installed on the slideway 7 of the slideway type support 6, and the output of the position se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com