Automatic centering device for elevator guiderail conveyer line

A technology of automatic centering and elevator guide rails, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of hidden dangers of workers, pushing to the outside of the conveyor line, collisions with the outer edge of the conveyor line, etc., to ensure accurate Performance and stability, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

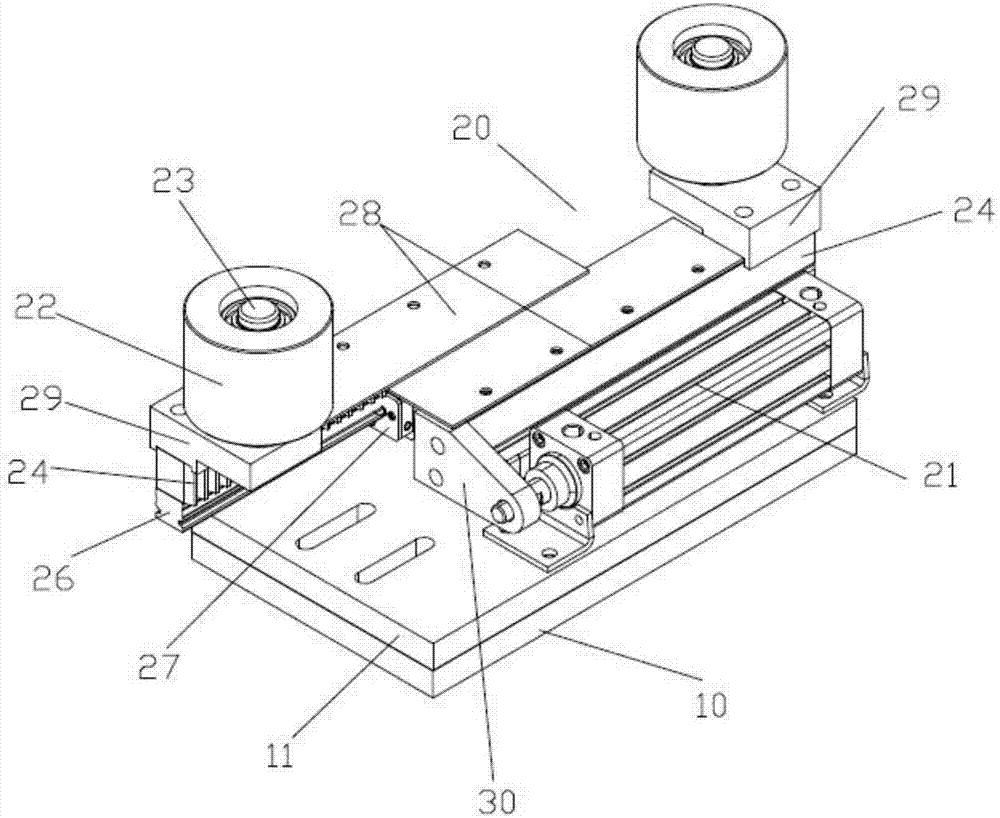

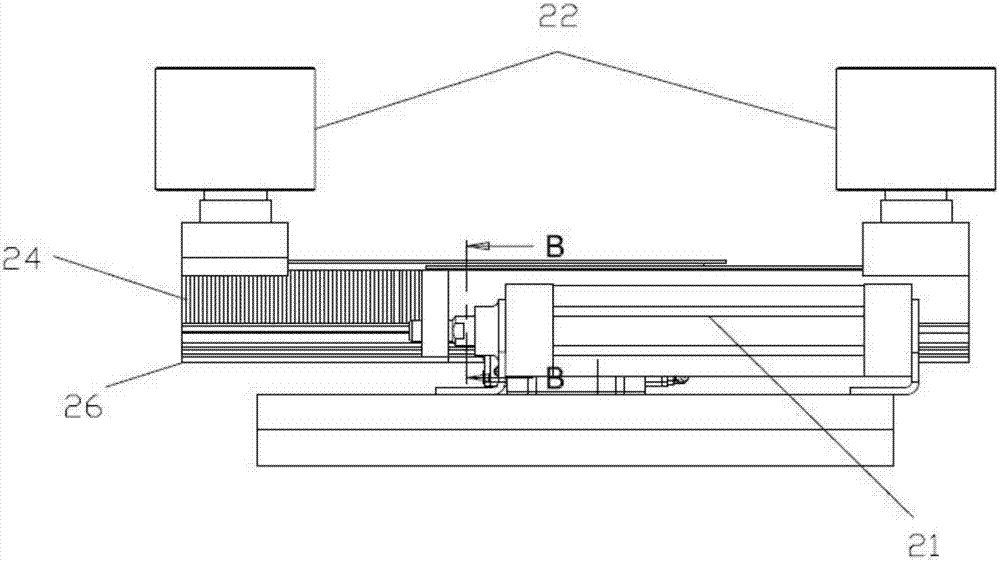

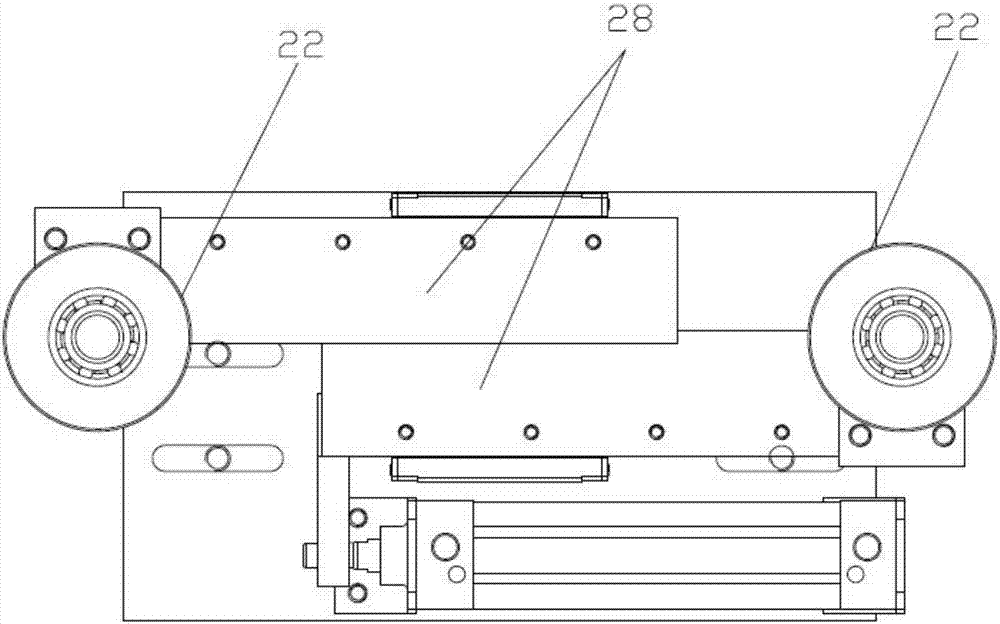

[0029] The elevator guide rail requires multiple processes to complete during the manufacturing process. Due to the long size and heavy weight of the guide rail, it is necessary to set up a conveyor line between the previous process and the next process. If it is not in place, or the guide rail of the elevator is shifted during the process, it is easy to collide with the outer edge of the conveyor line. In serious cases, it will be pushed directly to the outside of the conveyor line, which will affect the progress of the conveyor. There are corresponding hidden dangers.

[0030] Aiming at the deficiencies in the prior art, the present invention provides an automatic centering device for the elevator guide rail conveying line, which can correct deviation in time during the conveying process of the elevator guide rail, prevent the hidden danger of elevator guide rail deviation, improve conveying efficiency, and ensure conveying safety.

[0031] The technical solutions of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com